Hydraulic Trimming Press

Hydraulic Trimming Press for Automotive

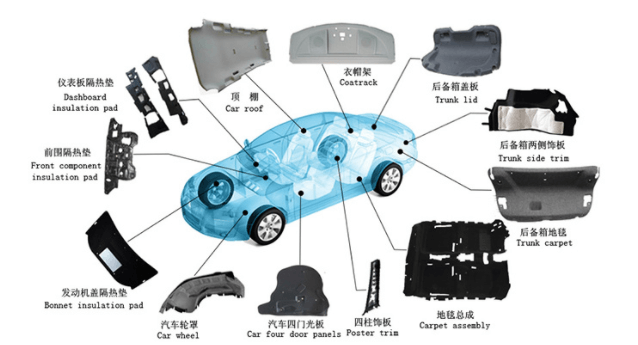

Commonly used automotive interior parts and accessories include car bumpers, hoods, air-conditioning shells, car shells, doors, interiors, rear axles, axle housings, frames, brake pads, car insurance films, etc. These fittings can all be press-molded by a hydraulic press.

The hydraulic trimming press machine is specially customized for automotive interior molding manufacturers (such as roofs, door leaves, sunroof panels, and rear frames). It is suitable for press molding, edge cutting, cutting, and other processes of automotive interior parts. It can also be used for the bending and flanging of metal parts.

The hydraulic press for forming automotive interior accessories has various structures such as four-column type and frame type.

Video

Watch the video below to learn more details.

Features of Hydraulic Trimming Press

1. The worktable of the hydraulic press for forming automotive interior parts has high guiding precision, good rigidity, and strong resistance to lateral force.

2. The cylinder is integrally forged and precision ground and has high reliability under high-pressure conditions.

3. The hydraulic control system adopts a plug-in basic system, which has reliable action, long service life, small hydraulic impact, and reduces connecting pipelines and leakage points.

4. The hydraulic trimming press machine adopts the electrical system controlled by a touch screen PLC, which has a compact structure, high precision, and good flexibility.

5. The upper limit of the roller has a safe locking structure. The photoelectric protection device is installed in front of the operation table to protect the equipment and ensure the safety of operation, mold replacement, and personal safety.

Applications of Hydraulic Trimming Press

This series of hydraulic presses are specially designed for the automotive interior parts industry. They are suitable for pressing, trimming, blanking, foaming, and other processes for automotive interiors, carpets, ceilings, storage boxes, and sound insulation cotton.

Zhengxi offers a hydraulic trim press for automobile interior trim parts that can be custom-built to fit the needs of high precision. We have offered the machines to many car manufacturers or first-tier suppliers of interiors, such as Hyundai, BMW, Volkswagen, Lamborghini, Ferrari, and so on.

H Frame Types Parameter

Model | unit |

| Specification model | ||||||

160T | 200T | 250T | 315T | 400T | 500T | 630T | |||

Nominal Force | KN | 1600 | 2000 | 2500 | 3150 | 4000 | 5000 | 630T | |

Return force | KN | 300 | 450 | 450 | 500 | 550 | 700 | 900 | |

Max liquid working pressure | MPA | 25 | 25 | 25 | 25 | 25 | 25 | 25 | |

Open height | mm | 1500 | 1500 | 1800 | 1800 | 1800 | 1800 | 1800 | |

Slider stroke | mm | 1200 | 1200 | 1400 | 1400 | 1400 | 1400 | 1400 | |

Effective worktable size | L-R | mm | 2400 | 2600 | 2600 | 2800 | 3000 | 3200 | 3500 |

F-B | mm | 1600 | 1600 | 1800 | 1800 | 2000 | 2000 | 2200 | |

Slider speed | down | mm/s | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

Press | mm/s | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 | |

Return | mm/s | 200 | 200 | 200 | 200 | 200 | 200 | 200 | |

Floor area and height | L-R | mm | 3700 | 4000 | 4000 | 4200 | 4400 | 4600 | 5000 |

F-B | mm | 2200 | 2200 | 2600 | 2600 | 2800 | 2800 | 3000 | |

H | mm | 5000 | 5200 | 5700 | 6200 | 6800 | 7000 | 7200 | |

Total power of equipment(approximately) | KW | 25 | 31 | 31 | 37 | 42 | 54 | 66 | |