The hydraulic press for making GMT block pallets is usually a piece of equipment specially designed to handle GMT (Glass Mat Thermoplastics) materials. The manufacturing process of GMT block pallets requires fiberglass-reinforced gypsum or thermoplastic resin to be pressed into block products of specific shapes and sizes. The hydraulic press uses the pressure and control provided by the hydraulic system to press the GMT material into the shape of the block pallet to meet the design requirements. These hydraulic press machines are often equipped with advanced control systems that can precisely adjust pressure, time, and temperature to ensure the manufacture of GMT block pallet products that meet standards.

GMT brick pallets are also known as composite brick pallets. It uses glass fiber as reinforcing material and thermoplastic resin as base material and is made by crushing, heating, cooling, pressurizing, and other methods. GMT block pallets are cheap and recyclable, durable, waterproof, temperature resistant, and lightweight. It is replacing traditional PVC brick pallets and wood brick pallets. To manufacture high-quality GMT block pallets, better raw materials and higher presses are required.

Manufacturing Process of GMT Brick Pallets

The raw materials for GMT brick pallets come from scraps of car interior decoration materials such as car ceilings, PE (polyethylene) floor mats, and car seat sets. Tear these raw materials into small pieces with a shredder. This shredded material is then accurately weighed into different sizes of brick pallets. And add other strong adhesive materials, such as PP, etc.

Wrap the weighed material in a soft, thick, high-temperature-resistant plastic tarp. Heat to high temperature using a heating machine. After a few minutes, the heated material is removed and placed on the press’s custom-sized mold. After finishing pressing, remove the GMT block tray from the mold.

Features of Hydraulic Presses for Making GMT Block Pallets:

- High pressure: The hydraulic press has high-pressure output capability and can effectively press GMT materials to ensure the compactness and strength of the product.

- Precise control: The hydraulic press is equipped with an advanced control system that can accurately control pressure, time, and temperature to ensure that the quality and size of the manufactured GMT block pallets meet the requirements.

- Strong durability: Hydraulic presses are usually made of high-quality materials, have good durability and stability, and can operate stably for a long time.

- Strong adaptability: The hydraulic press can be adjusted according to different GMT block pallet designs and requirements to adapt to different production needs.

Benefits of Hydraulic Press for Manufacturing GMT Block Pallets:

- Improve production efficiency: The hydraulic press can quickly and efficiently manufacture GMT block pallets, improving production efficiency and reducing production costs.

- Stable product quality: Through precise pressing and control, the hydraulic press ensures the stable quality of GMT block pallets with good physical properties and appearance.

- Environmental protection and sustainability: The manufacturing of GMT block pallets uses renewable materials such as fiberglass and gypsum, which is conducive to environmental protection and sustainable development.

- Customized design: The hydraulic press can be customized according to customer needs to meet the manufacturing requirements of GMT block pallets of different shapes, sizes, and functions.

Application of Hydraulic Press for Making GMT Block Pallets

The manufacture of GMT block pallets is one of the main applications of this hydraulic press. The GMT block pallet hydraulic press mainly presses the mixed GMT materials pre-placed in the mold into block pallets of the required shape and size through the high pressure provided by the hydraulic system. This kind of pallet is usually used for consignment, transportation, and storage, and is widely used in the logistics industry, manufacturing, and warehousing industries.

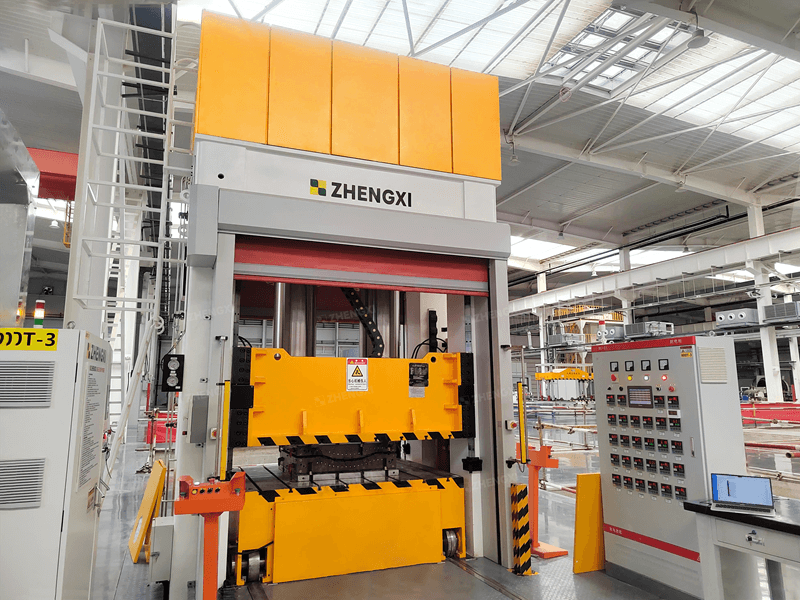

Zhengxi is a well-known hydraulic press factory in China, that provides high-quality hydraulic presses for making GMT block pallets. In addition, we also provide FRP manhole covers hydraulic presses, hydraulic presses for FRP septic tanks, and composite pallet presses. If you have any needs, please contact us.