FRP septic tanks are mainly cylindrical integral septic tanks made of polymer materials and high-strength glass fiber-reinforced plastics. Its product substrate is an SMC sheet molding compound. It is molded by a special SMC hydraulic press through high temperature and high pressure.

FRP septic tank has the characteristics of high strength, corrosion resistance, wear resistance, high-temperature resistance, sound insulation, and leakage resistance. In addition, it has a beautiful surface appearance, is durable, and has a long service life. It has successfully solved the problems of leakage of brick structure septic tanks, short service life, poor operating conditions, difficult maintenance, high cost of reinforced concrete septic tanks, and long construction period. It is the first choice to solve the waste.

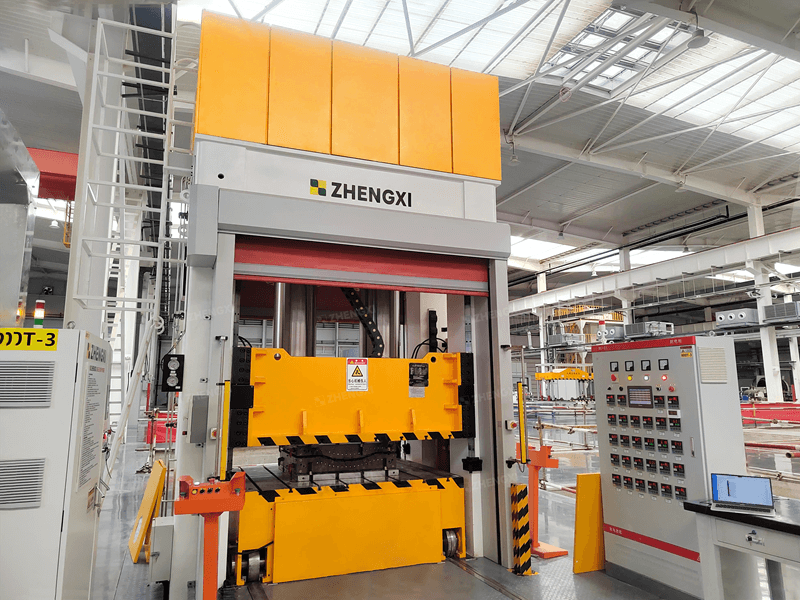

The Process of SMC Hydraulic Press Molding FRP Septic Tank

The main tool used in the manufacture of FRP septic tanks is the SMC hydraulic press. Put a certain amount of molding material into the metal mold of the SMC hydraulic press. Under a certain temperature and pressure, the molding compound is heat-plasticized in the cavity, flows under pressure, and fills the cavity to form a cycle.

The compression molding process requires heating and pressure during the molding process, so that the molding compound is plasticized to generate flow and fill the cavity, and the resin is cured. When the composite molding compound flows to fill the cavity, not only the resin flows but also the reinforcing material flows, so that the resin and fibers fill all parts of the cavity at the same time.

Zhengxi is a professional hydraulic press factory in China that provides high-quality SMC hydraulic presses. FRP septic tank manufacturers can contact us to purchase related machines.

Advantages of FRP Septic Tanks

- Anti-leakage. The product is formed by one-time compression molding of high-strength acid and alkali-resistant materials such as glass fiber and organic resin. The sealing performance is good, and it is not easy to cause fracture and damage caused by foundation settlement and scum layer on the inner plate of the pool. The problem of groundwater pollution by brick septic tanks is solved. It ensures the reliable operation of the septic tank and the function of anaerobic septic.

- High compressive strength. The FRP septic tank adopts an arched structure design, which has high compressive strength and uniform pressure.

- Long service life. The product is resistant to moisture, acid and alkali, oxidation, stretching, impact, high strength, and is not easy to deform at high and low temperatures.

- Good sealing. Not easy to leak, can effectively handle feces. The effect of anaerobic decay is better than that of traditional septic tanks, and it can prevent secondary pollution caused by groundwater leakage in traditional septic tanks. At the same time, it can improve the damage to the building caused by the softness and subsidence of the foundation.

- High economic benefit. It is molded by a super-large SMC hydraulic press through high temperature and high pressure. Factory production, mechanization, and mass production. Using new technology and new materials, it is small in size and large in effective volume. The overall cost is 80% of the reinforced concrete structure.

The Application of FRP Septic Tank

The product is formed at one time, integrally sealed, not easy to leak, high strength, impact resistance, large compressive load, acid and alkali resistance, corrosion resistance, light and durable, simple and convenient installation, economical and affordable, good sewage treatment effect, convenient water storage, and easy to use, long life, spliced into different volumes.

It is suitable for domestic sewage treatment in general industrial enterprises and civil buildings, residential communities, office buildings, hotels, restaurants, schools, hospitals, barracks, public toilets, buildings where people live, and industrial and mining enterprises. It can also be used as an oil-water filter pool for firefighting cisterns, accident emergency pools, micro-water irrigation cellars (water tanks), hotels, restaurants, and other places.