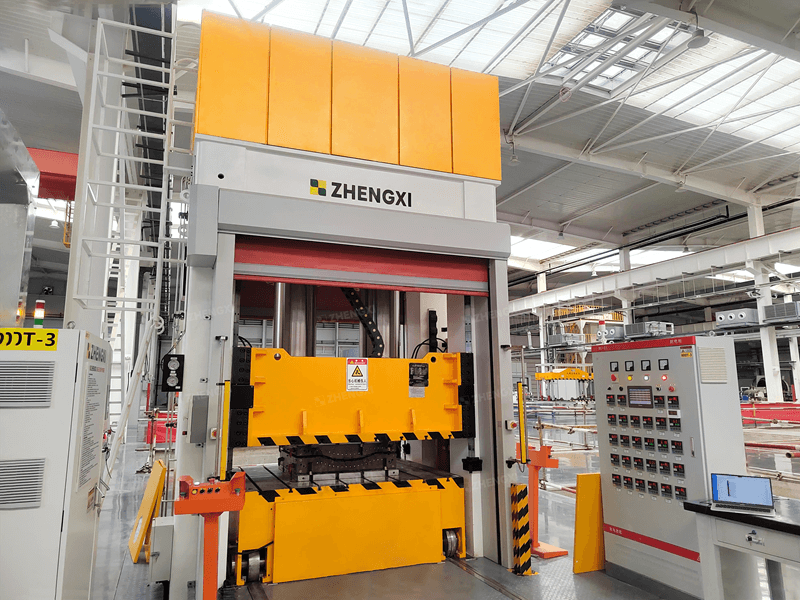

Plant fiber composite tray is a new product in the tray market. After the plant fiber material is crushed, it is molded at one time under the conditions of high temperature and high pressure. Hydraulic press is a critical pressure equipment. It provides all the pressure required for press molding. Due to the different specifications of the plant fiber composite pallets, the hydraulic presses used have different tonnages. The following is an 1200-ton new plant fiber composite pallet hydraulic press machine.

The molded plant tray is made of wood chips, hunting stalks, waste chemical fibers, etc., and is pressed and formed by a stamping press. Our 1200-ton plant fiber composite tray molding machine has an independent hydraulic system. It has good stability, high production efficiency, and low energy consumption. And it can be used for steam or thermal oil heating. Flexible and changeable, easy to change molds, and can produce pallets of various specifications. Easy to install, no foundation positioning required. It can be produced by placing it flat.

The plant fiber composite pallet hydraulic press has a reasonable design structure. High positioning accuracy and precise and balanced mold closing. Liquid filling and rapid pressurization can be fully pressurized in 35 seconds. Easy and simple to operate. Just lay the sawdust inside the mold and press the work button. The press can automatically complete the entire process of pressing down, adding pressure, limiting pressure, maintaining pressure, timing, releasing pressure, demoulding, and rising to the position. The pressing and curing time for molding a tray is about 400 seconds.

Features of the 1200-ton Plant Fiber Composite Tray Hydraulic Press:

- Structural design

The method used by the plant fiber composite pallet molding hydraulic press is computer optimization. Its design matches its name very well. The raw material it welds is all steel plate material. - Operation mode

During use, the frame-type wood-plastic fiber composite tray hydraulic press uses buttons to centralize the machine for easy control. - Guidance

The accuracy of the direction guided by the plant fiber composite pallet molding machine is relatively high. Its ability to resist pressure is relatively strong. It is mainly biased toward carrying capacity. This ability is its main potential. - Slider

It adopts four-corner and eight-sided full-length guide rails, with high adjustment accuracy and high rigidity. It is not easy for precision deviation to occur after adjustment. - Equipped with multiple sets of accumulators

When moving at low speed, the flow required by the load is less than the hydraulic pump flow. The excess flow of the hydraulic pump is stored in the accumulator. When the load-required flow rate is greater than the hydraulic pump flow rate, the liquid is released from the accumulator to supplement the insufficient flow rate of the hydraulic pump. When the machine is shut down but still needs to maintain a certain pressure, the hydraulic pump can be stopped and the accumulator can compensate for system leakage to maintain system pressure.

- Equipped with PLC and servo-hydraulic control system

The plant fiber composite pallet hydraulic press can be operated with one click. It has the characteristics of high efficiency, energy saving, low noise, low heat generation, high control accuracy, and easy maintenance. - Machine structure and composition

The 1200-ton plant fiber composite tray hydraulic press machine has a gantry frame structure. It is mainly composed of machine height, hydraulic cylinder, hydraulic system, power mechanism, and mobile workbench. It is connected through pipelines and hand pumps to form an overall operation. The hydraulic system consists of a main cylinder, a manual pump, a control valve, a pipeline, a fuel tank, a pressure gauge, and other additional control valves. Use the manual pump to control the driving cylinder, or the electric drive to drive the slider to move downward. The return journey completes various process actions through pressure relief and spring return.

Precautions for Use of 1200-ton Frame-type Plant Fiber Composite Tray Hydraulic Press Machine:

- When the slider drives the mold to press up and down, it is forbidden to put hands and heads into the working part of the pressing plate and mold.

- When the equipment is working, pressing, stretching, welding, cutting, bending, and twisting are strictly prohibited.

- Smoking, welding, and cutting are not allowed around the frame hydraulic press. Do not store flammable and explosive items, etc.

- When the 1200-ton frame-type plant fiber composite pallet molding machine is finished, the power supply should be cut off. Wipe clean equipment uprights and piston rods. Add lubricating oil, and clean the mold and workpiece.

- If the machine is running abnormally, cut off the power immediately.

- When adjusting the 1200-ton frame hydraulic press, the power supply must be cut off. Pay attention to the safety of your hands when moving the workpiece.

- All components of the 1200-ton plant fiber composite tray molding machine must be maintained regularly.

Plant Fiber Composite Pallet Hydraulic Press Machine Application:

Recycled raw materials: waste wood, waste wood chips, sawn chips, wood shavings, wood chips, logs, planks, tree branches, wood, wood chips, and waste pallets, etc. These fiber-rich materials can be used to produce composite pallets.

The plant fiber composite tray hydraulic press designed by Chengdu Zhengxi Hydraulic Equipment Co., Ltd. has many styles. Available for different standardized processing requirements. Customers in need can contact us immediately.