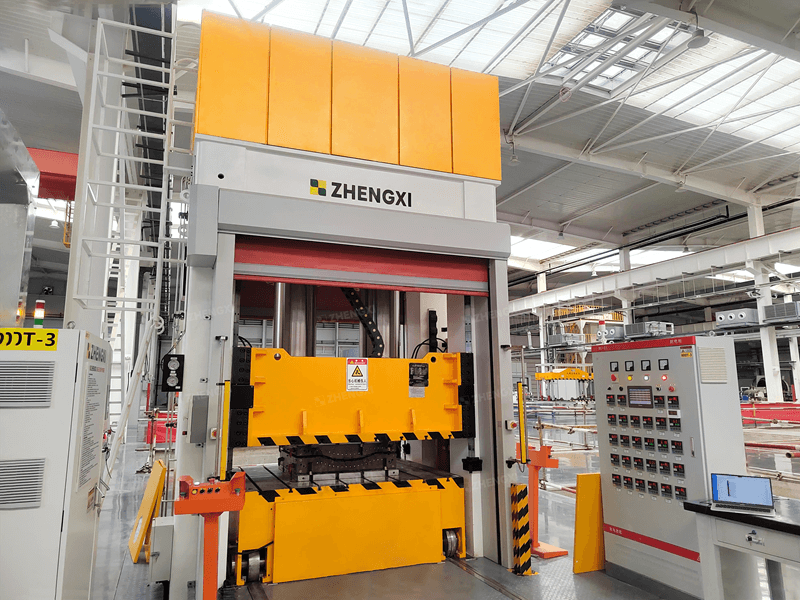

FRP water tanks are generally made by using an FRP water tank panel-making hydraulic press and supporting molds using an integral molding and one-time molding process. Fiberglass water tanks have the advantages of corrosion resistance, high strength, lightweight, and beautiful appearance. They are currently a popular type of water tank.

The FRP water tank hydraulic press is easy to operate and the working parameters are adjustable. The system can be configured with an in-mold core pulling control system and a preset in-mold ejection control system. It can realize a series of actions such as rapid descent, segmented compression, segmented deflation, working, pressure maintaining, slow mold opening, rapid return, slow demoulding, rapid ejection, ejection stop, rapid return, etc. The temperature can be Multi-point control.

Users can choose the appropriate FRP water tank forming hydraulic press according to their own parameter requirements. Generally, a three-beam and four-column structure is used. The tonnage can be selected according to the size of the water tank, such as 315 tons, 400 tons, 500 tons, 630 tons, 800 tons, and another different tonnage FRP water tank making hydraulic presses. This kind of equipment needs to be used in an environment of 0°C to 40°C, with an appropriate range of 40% to 95%. It adopts a 380V three-phase four-wire voltage system, and the voltage fluctuation is 380V±10%50HZ.

Features of 800-ton FRP water tank panel-making hydraulic press:

- The fuselage adopts a computer-optimized design and is an all-steel plate four-pillar structure. And after fireplace tempering or vibration aging, the accuracy is maintained well.

- The slider adopts a four-pillar guide rail guide, which has good adjustment accuracy, strong rigidity, and good accuracy retention.

- New cylinder sealing components have strong reliability and long service life.

- The slider of the molded FRP water tank panel forming hydraulic press runs fast and has high working efficiency.

- Hydraulic control adopts a cartridge valve integrated system. Reliable operation, large flow, small internal leakage, and long service life. The system is highly integrated, reducing connecting pipes and leak points.

- The working pressure of the slider, the stroke range of no-load rapid descent, and slow working advance can be adjusted according to process needs.

- Through the operation panel, two molding processes of fixed stroke and fixed pressure can be realized. It also has functions such as pressure holding and delay.

- The FRP water tank panel-making hydraulic press has an independent electrical control system, making the equipment reliable in operation, objective in action, and easy to maintain.

Fiberglass water tank panel forming hydraulic press machine processing technology:

The processing method of a fiberglass water tank is to put a certain amount of molding material into a pair of metal molds. Under a certain temperature and pressure, the molding compound is heated and plasticized in the mold cavity, flows under pressure, and fills the mold cavity to form the mold. The compression molding process requires heating and pressure during the molding process so that the plasticization of the molding material creates a flow that fills the mold cavity and causes the resin to undergo a curing reaction. When the composite molding material flows and fills the mold cavity, not only the resin flows, but the reinforcing materials also flow, so that the resin and fibers fill all parts of the mold cavity at the same time.

- Put an appropriate amount of fiberglass molding material into the mold.

- Add metal parts to improve the strength of the product or serve as a connection.

- Put the fiberglass molding material again to cover the metal parts.

- Start the fiberglass water tank panel making hydraulic press to suppress the raw materials.

- Heating and curing, pay attention to the heating time.

- After the heated and completely solidified raw materials cool down, the product in the mold can be removed.

- Grind, turn, drill, polish, and other processes on the molded products as required.

FRP water tank panel forming hydraulic press is specially used for molding HMC, TMC, FRP composite molding powder products, DMC, BMC lump (bulk) FRP molding plastic products, SMC, PLSMC, sheet FRP molding plastic products, FRP adsorption compression molding of preform molding plastic products, molding of fiberglass short fiber molding plastic products.

800T FRP Water Tank Panel Making Hydraulic Press Technical Parameter Table:

| Model/technical parameters | 630T | 800T |

| Nominal pressure(KN) | 6300 | 8000 |

| System pressure (Mpa) | 25 | 25 |

| Slider stroke (mm) | 700 | 800 |

| Maximum opening height (mm) | 1200 | 1300 |

| Effective area of workbench (mm *mm) – Left and right (distance between columns) | 1500 | 1800 |

| Effective area of workbench (mm *mm) – Front and back (from the front to the back of the workbench) | 1400 | 1500 |

| Idle travel downward speed (mm/s) | 180 | 180 |

| Pressing speed (mm/s) | 5-15 | 5-15 |

| Return speed (mm/s) | 150 | 150 |

| Lower top cylinder (T) | 120 | 150 |

| Lower top cylinder stroke (mm) | 200 | 200 |

| Motor power (KW) | 22*2 | 22*2 |

| Height of workbench from ground (mm) | 850 | 900 |

FRP Water Tank Panel Making Hydraulic Press Video

In addition to FRP water tank panel-making hydraulic presses, Zhengxi Hydraulic can also produce FRP septic tank molding machines, FRP meter molding hydraulic presses, composite panel molding machines, SMC/BMC molding machines, FRP automotive diversion/bumper molding machines, etc. Customers can customize it as per their requirements. Contact us now!

Related Blogs: