The rainwater storage tank is a rainwater collection facility that covers a large area. Generally, it can be built under public areas such as city squares, green spaces, and parking lots. Its main function is to temporarily store the peak flow of rainwater runoff in it, and then slowly discharge the rainwater from the storage tank after the maximum flow drops. In this way, it can not only avoid the rainwater flood peak, realize the recycling of rainwater, but also avoid the pollution of the receiving water body by the initial rainwater, and also play a positive role in the drainage scheduling between drainage areas.

The location of the FRP rain water tank is generally set in the main rainwater pipe (canal) or at the intersection of large flow, or near the place with large water consumption, so as to make the layout of the whole system reasonable and reduce the engineering volume of the pipe (canal) system. It can be set up separately for a single building, or it can be set up in a group of buildings or areas.

FRP storage tank is a cylindrical container made of a composite material with unsaturated polyester resin (UPR) as the matrix material. It is characterized by lightweight, high strength, corrosion resistance, can withstand large loads, and has good anti-aging performance.

The underground fiberglass tanks are mainly used in roof rainwater collection systems in cities and factories. It adopts a non-powered fluidization design, has a unique water distribution system, and does not require special management. The FRP tanks have good integrity, no cracks, easy installation, and strong adaptability.

Features of Fiberglass Tanks for Sale

- The underground FRP tanks are produced in a monolithic shape with good sealing performance. No leakage, no pollution of surface water, and no corrosion of flowers, trees, wires and cables around the reservoir. In the pool, the high-level siphon is used to guide and dredge, and it has been precipitated and purified many times.

- The rainwater storage tank is made of new material FRP, which is resistant to aging, acid and alkali, and has a service life of more than 50 years.

- The fiberglass tanks adopt the buried type, with no power, no maintenance, and no management in the later period.

- The underground fiberglass tanks are produced in a factory, mechanized, batch, and integral form. Using new technology and new materials, it is small in size and large in effective volume.

In addition to being used for rainwater collection, FRP tanks are also widely used in the chemical industry. It can store various corrosive liquids, such as organic acid solutions such as sulfuric acid and hydrochloric acid, or neutral liquids such as alcohols, and other strong oxidizing chemical media. The number of cleanings is greatly reduced due to the smooth and smooth inner wall of these containers without stagnation. This saves manpower and material resources, reduces labor costs, and improves work efficiency.

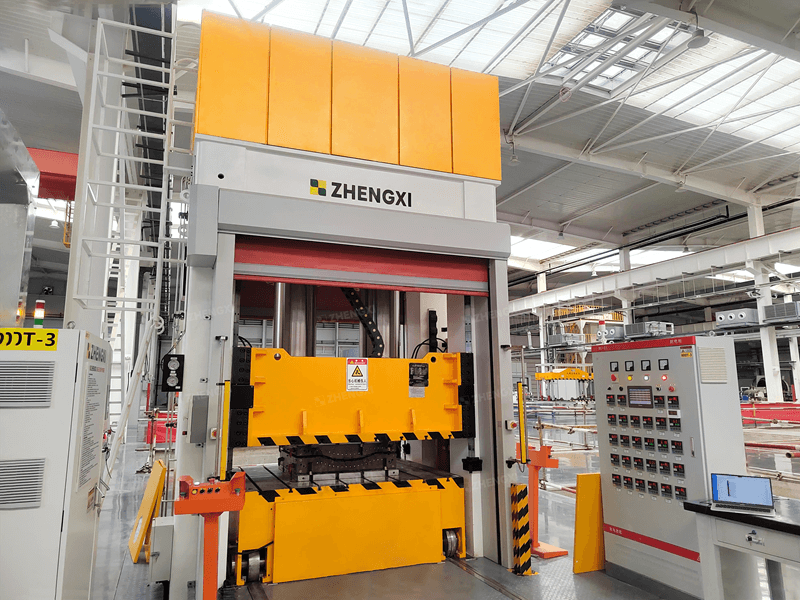

FRP Tanks Manufacturers Choose to Use SMC Hydraulic Presses

The main function of the SMC hydraulic press is to press the SMC sheet (commonly known as FRP) in a metal mold to produce FRP products.

The SMC molding machine adopts a three-beam and four-column structure, which has a strong anti-eccentric load capacity. Under full load, the eccentric load of the slider does not exceed 150mm. Good rigidity and precision retention, the body rigidity is higher than 1/6000. There is a fully welded 30mm skirt around the workbench on the top of the machine, and holes are installed at convenient places to install oil pipes to facilitate recovery of oil leakage. After the welding of the fuselage parts is completed, tempering treatment is carried out to eliminate the internal stress of the structure.

Zhengxi is a professional composite hydraulic press factory in China, providing high-quality SMC molding presses. The main cylinder of our SMC compression molding machine adopts a two-cylinder or three-cylinder structure, arranged in a horizontal line. The cylinder body is forged with high-quality steel, and the oil cylinder is sealed with domestic high-quality sealing rings. The slider is welded with high-quality steel. T-slot spacing and dimensions are to be determined by the purchaser. The slider is equipped with a locking device, the upper and lower positions of the stroke are limited, the slider can be stopped and locked at any position, and it is guaranteed not to slide down when it is still. The installation of the main cylinder adopts rigid body thread prohibition to ensure the safety of the working cylinder.

Zhengxi’s SMC hydraulic press is the first choice for FRP rain water tank manufacturers. It is not only safe to use but also durable. If you are interested, please contact us.