The SMC (Sheet Molding Compound) molding machine is specially used to mold SMC materials. It is widely used in automobiles, electrical, construction, aerospace, and other fields. Its characteristics are mainly reflected in the following aspects:

1. High Precision and High Stability

- Precise pressure control: SMC molding machine adopts an advanced hydraulic or servo control system, which can accurately control the molding pressure to ensure the density and dimensional accuracy of the product.

- Uniform temperature control: Equipped with an efficient heating and cooling system, it can evenly heat the mold to avoid product defects caused by uneven temperature.

- Good repeatability: Since parameters such as pressure, temperature, and time can be precisely controlled, the repeatability and consistency of the product are high, which is suitable for large-scale production.

2. High Efficiency and Automation

- Rapid prototyping: SMC molding presses have a short molding cycle and can usually complete a molding process within a few minutes, with high production efficiency.

- High degree of automation: Modern SMC molding machines are usually equipped with automatic loading and unloading systems, mold quick change devices, etc., to reduce manual intervention and improve production efficiency.

- Energy saving and environmental protection: By optimizing the heating and cooling systems, energy consumption is reduced, while waste generation is reduced, which meets environmental protection requirements.

- Strong and wide material adaptability: Not only suitable for SMC materials and compression molding of composite materials such as BMC (Bulk Molding Compound) and GMT (Glass Mat Thermoplastic).

- Various product shapes: It can produce products of various complex shapes, such as automotive parts, electrical housings, architectural decorative parts, etc. Convenient mold replacement: The mold design is reasonable and easy to replace, suitable for the production needs of multiple varieties and small batches.

3. Excellent Product Performance

- Good mechanical properties: SMC materials have the advantages of high strength, high modulus, corrosion resistance, etc., and the mechanical properties of compression molded products are excellent.

- High surface quality: The compression molding process can smooth the product’s surface and reduce the subsequent processing steps.

- Lightweight: SMC material has low density and light product weight, making it suitable for fields with strict weight requirements, such as automobiles, aerospace, etc.

4. Easy Operation and Maintenance

- Friendly operation interface: Equipped with a touch screen or human-machine interface, the operation is intuitive and straightforward, which is convenient for workers to get started quickly.

- Easy maintenance: The equipment has a reasonable structure, key components are easy to disassemble and replace, and the maintenance cost is low.

- High safety: Equipped with multiple safety protection devices, such as overload protection, emergency stop button, etc., to ensure safe operation.

5. High Cost-effectiveness

- Quick return on investment: The cost can be quickly recovered due to high production efficiency and good product quality.

- Long service life: The equipment is made of high-quality materials and advanced technology, with a long service life and low long-term operating cost.

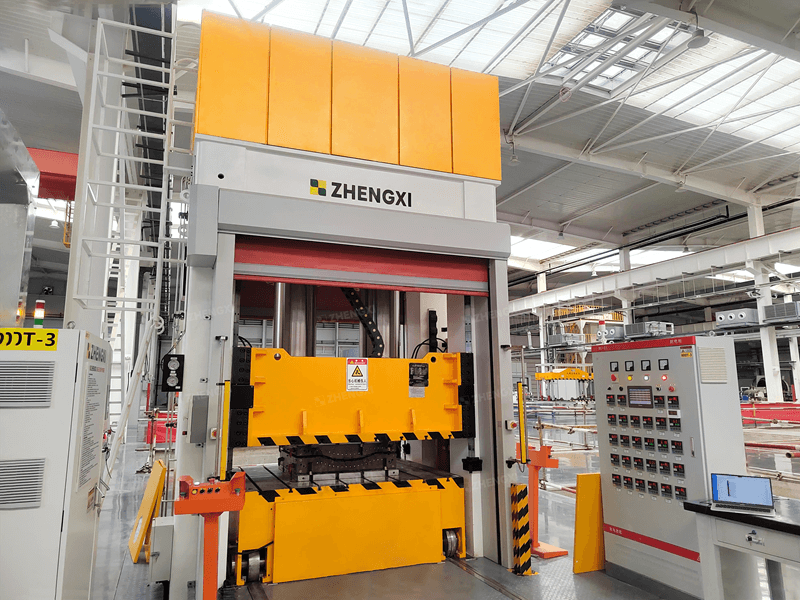

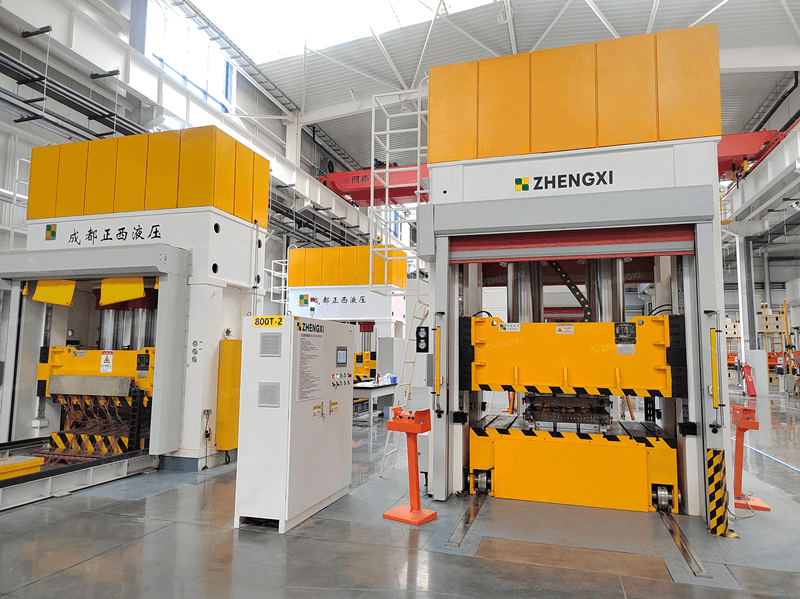

Chengdu Zhengxi, as a famous hydraulic press factory in China, provides high-quality SMC molding machines. If you have any needs, contact us!