FRP cable trays are a type of cable management system commonly used in various industries to support, protect, and organize electrical cables and wires. They are made from a combination of fibers (such as glass, carbon, or aramid) embedded in a plastic resin matrix. FRP cable protection covers offer several advantages over traditional metal cable trays, including corrosion resistance, lightweight construction, and excellent strength-to-weight ratio.

These cable trays are designed to provide a safe and efficient solution for routing and supporting cables in different environments, such as industrial plants, commercial buildings, power plants, and more. They come in various shapes, sizes, and configurations to accommodate different cable layouts and installation requirements. FRP cable trays are often used in applications where exposure to corrosive chemicals, extreme temperatures, or high humidity levels is a concern.

Key Features and Benefits of FRP Cable Trays Include:

- Corrosion Resistance: FRP cable protection covers are inherently resistant to corrosion caused by chemicals, moisture, and environmental factors. This makes them suitable for installation in harsh and corrosive environments.

- Lightweight: Compared to traditional metal cable trays, FRP cable trays are lightweight, making them easier to handle, transport, and install.

- Strength: Despite their lightweight nature, FRP cable trays offer excellent strength and durability, making them capable of supporting a range of cable loads.

- Electrical Insulation: FRP is an electrical insulator, which adds an extra layer of safety when handling cables and prevents any potential electrical interference.

- Easy Installation: FRP cable boxes are often designed with user-friendly features that facilitate quick and straightforward installation. They can be cut, bent, and assembled to fit specific cable routing requirements.

- Fire Resistance: Depending on the specific composition of the FRP materials used, these cable trays can exhibit good fire resistance, contributing to overall safety in installations.

- Design Flexibility: fiberglass cable boxes can be manufactured in a variety of profiles and configurations, allowing for customization based on the specific needs of the installation.

- Low Maintenance: Due to their corrosion resistance and durability, FRP cable trays generally require less maintenance compared to metal alternatives.

- Longevity: Properly designed and installed FRP cable trays can have a long service life, especially in environments where corrosion is a concern.

FRP protection covers are available in various types, such as ladder trays, solid bottom trays, perforated trays, and trough trays. The choice of tray type depends on factors like cable capacity, ventilation requirements, and the specific environment in which they will be installed.

Overall, FRP cable trays offer a reliable and versatile solution for cable management needs, particularly in settings where resistance to corrosion and environmental challenges are important considerations.

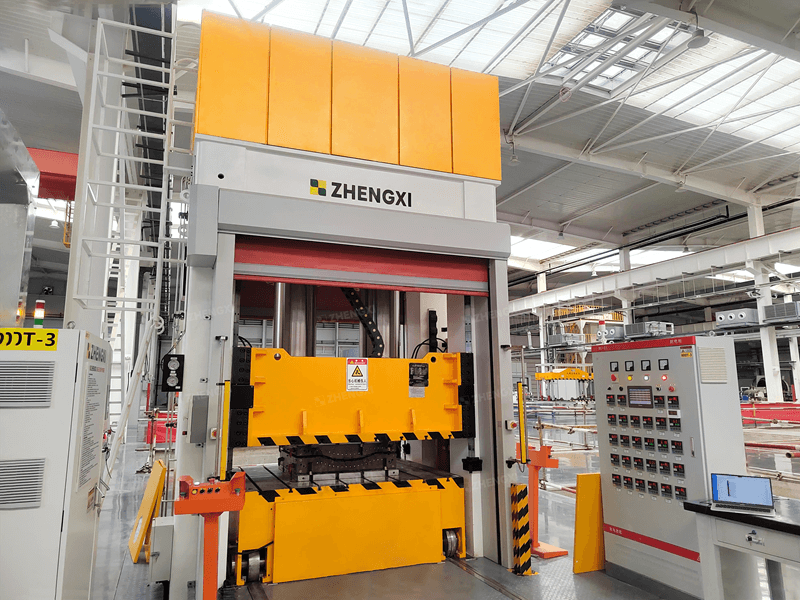

Use SMC Hydraulic Press to Make FRP Cable Trays

An SMC press machine is a specialized piece of equipment used in the manufacturing process of FRP cable protection covers. This machine plays a crucial role in shaping, consolidating, and curing the layers of FRP materials to create the final cable tray product. Here’s an overview of the components and functions of an FRP cable tray press machine:

1. Frame and Structure

The press machine features a sturdy frame and structure designed to withstand the pressures and forces exerted during the pressing process. It ensures stability and safety during operation.

2. Hydraulic System

The heart of the press machine is its hydraulic system. It includes hydraulic cylinders, pumps, valves, and controls that generate and regulate hydraulic pressure. The hydraulic system is responsible for applying controlled pressure to the FRP materials, ensuring proper consolidation and curing.

3. Heating Elements

Many FRP cable tray press machines are equipped with heating elements. These elements facilitate the curing process of the resin used in the FRP materials. They help maintain a consistent temperature within the press, which is critical for achieving optimal curing of the materials.

4. Mold Setup

The press machine is designed to accommodate the molds used for forming the FRP cable trays. The molds are positioned within the press and hold the layers of FRP sheets, resin, and reinforcements in the desired shape and configuration.

5. Pressure Control

The hydraulic system allows operators to control the amount of pressure applied during the pressing process. This control is essential to ensure proper bonding between layers and to achieve the desired mechanical properties in the finished cable tray.

6. Temperature Control

If equipped with heating elements, the press machine includes temperature controls. Operators can set and monitor the temperature inside the press to ensure that the curing process occurs within the specified temperature range for the resin being used.

7. Safety Features

Modern press machines are equipped with various safety features, such as emergency stop buttons, safety interlocks, and pressure relief valves. These features help prevent accidents and ensure operator safety.

8. Control Panel

The press machine’s control panel allows operators to adjust and monitor various parameters, including pressure, temperature (if applicable), and cycle times. It provides a user-friendly interface for efficient machine operation.

The process of using an FRP cable tray press machine involves assembling layers of FRP sheets, resin, and reinforcements within a mold, applying pressure to consolidate the layers, and then curing the materials at an appropriate temperature. This results in a strong and durable FRP junction box that can be used for cable management in various industrial and commercial applications.

It’s important to note that the specific design and features of an SMC hydraulic press machine may vary based on the manufacturer and the intended production scale. Manufacturers’ guidelines and operating manuals should be followed closely to ensure the safe and effective use of the press machine. Zhengxi is a famous hydraulic press factory in China and provides high-quality hydraulic press machines. If you have any needs, please contact us.