The head forming machine is also called the head stretching machine, the head cold press machine, or the head molding machine. It is a hydraulic press specially used for the head molding of large oil tanks and natural gas tanks.

The head refers to the end caps at both ends of the metal closed container, which is the pressure-bearing part of the pressure vessel. It is a metal cylindrical container, generally a rotary shell. According to the shape of the surface, the head can be divided into a hemispherical, elliptical, dish-shaped spherical crown, conical shell, and flat cover. It can not only ensure strength but also meet the needs of safe use. Among them, spherical, oval, dish-shaped, and spherical-shaped heads are collectively referred to as convex heads. They are used in various container equipment, such as oxygen cylinders, gas, natural gas tanks, heat exchangers, towers, reactors, boilers, and separation equipment.

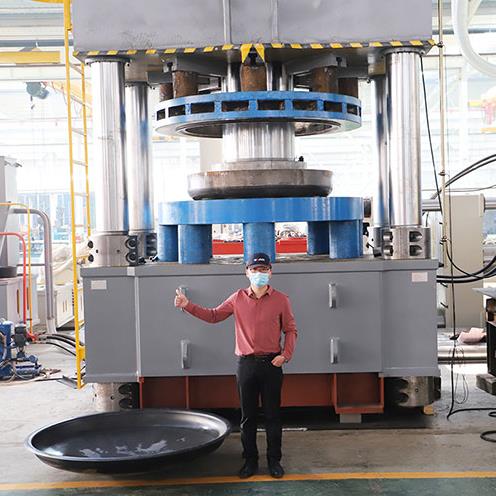

The production of the head is generally stamped or stretched by a hydraulic press. Zhengxi’s metal head forming presses are specially designed for pressing heads of various specifications and pressure-volume end caps. It has the characteristics of high production efficiency and a good molding effect. It has affected the head market for more than ten years. The commonly used tonnages are 1000 tons, 1600 tons, 1200 tons, 2000 tons, 2500 tons, 3000 tons, and so on. The head pressed by this machine is formed by cold pressing once, without heating, and can press the head with a diameter of 2800mm or less.

Table of Content:

- The Main Structure of the Head Forming Hydraulic Press

- The Composition Characteristics of the Head Forming Machine

- Advantages of Head Stamping Machine

- Optional Equipment for Head Forming Machine

- Metal Tank Head Forming Machine Conditions of Use

- Applications of Head Forming Press

The Main Structure of the Head Forming Hydraulic Press

- Main engine: The fuselage is composed of an upper beam, a movable beam, a lower beam, and 4 columns. The main oil cylinder adopts a single-cylinder structure.

- Hydraulic control system

- Electrical control system

- Lubrication system

- Safety protection system

The Composition Characteristics of the Head Forming Machine

- According to its material and process, the head-forming machine is divided into cold pressing head forming machine and hot pressing head forming machine. The body of the head stretching hydraulic press adopts a four-column or pre-tensioned split frame structure. Generally, the head stretching hydraulic press for formed parts adopts a four-column type. The structure is simple, economical and practical, and is guided by four columns. The headpiece with high precision requirements adopts a prestressed frame structure and is guided by four-cornered and eight-sided plane guide rails, with high guiding precision and strong anti-eccentric load capacity.

- The stretching head forming press and production line are mainly composed of the main engine, stretching cylinder, edge cylinder, hydraulic system, electrical system, lubrication system, cooling system, and other parts. The main machine includes an upper beam, lower beam, column, nut, stretching slider, blank holder slider, mobile workbench, and so on. Its fuselage is connected by 16 nuts and four columns, which is a closed structure with sufficient rigidity and strength. The tie rod is fastened by the hydraulic pre-tightening method to ensure the rigidity of the whole machine.

- The main cylinder assembly is installed in the upper beam. Stretching sliders and blanking sliders are installed between the upper and lower beams. The upper plane of the stretching slider is connected with the main oil cylinder assembly by bolts. The stretching dies connecting cylinder is installed on the lower plane of the stretching slider. The connecting cylinder is clamped by a quick-change oil cylinder. The blank holder cylinder is installed in the stretching slider, and the lower end is connected to the blank holder slider through a flange. A quick-change die ring device is installed in the blank holder slider. The lower beam is equipped with an ejection rotating device, which is used for ejecting and rotating oiling after the workpiece is stretched. The upper plane of the lower beam is equipped with a mobile worktable and its lifting and clamping device, positioning device, and bonding detection device. The guide of the column and the slider is made of alloy material, which has high hardness, good wear resistance, and high guide precision.

- The power part of the hydraulic system of the metal tank head forming machine consists of three upper and lower oil tanks. The upper oil tank is arranged at the rear of the upper beam or placed on the top of the upper beam to provide power oil for the equipment stretching cylinder and edge pressing cylinder.

Advantages of Head Stamping Machine

- The prestressed combined frame improves the anti-fatigue strength of the frame and the rigidity of the equipment, which is beneficial to ensure the quality of the product.

- Double ball hinge rocker type multi-working cylinder structure. It reduces the additional constraints of multiple cylinders on the movable beam and the additional force on the guide sleeve and seal of the oil cylinder, prolonging the life of the seal and guide sleeve.

- “X” shaped plane guide structure. High guiding precision, long life of the guide plate, and little influence of heat radiation.

- Dimensional accuracy control of stamping parts. The precision level of the equipment reaches the precision level, which can meet the higher precision requirements of stamping parts.

- The computer-controlled blank holder force curve changes with the surface design technology. The change curve is pre-imported through the man-machine interface, and the size of the blank-holding force is infinitely controlled by the computer.

Optional Equipment for Head Forming Machine

- Mobile workbench

- Punching buffer device

- The four corners of the blank holder slider and the hydraulic cushion are respectively pressure-adjusting devices (stretching asymmetrical parts).

- Photoelectric protection device

- Floating rails and rolling brackets for touch

- Mold quick clamping mechanism

- Stroke, pressure, digital display digital device control device

- Touch industrial display

- Hydraulic system heating and cooling device

Metal Tank Head Forming Machine Conditions of Use

- Equipment working area temperature: 0~50℃ (±)

- Power supply: three-phase four-wire system 380V, 50HZ, voltage fluctuation range 380V±10%

- Cooling method: water cooling device

- The medium used in the hydraulic system: No. 46 anti-wear hydraulic oil

Applications of Head Forming Press

Zhengxi is a professional hydraulic press factory in China that provides high-quality metal tank head forming machines. If you have any needs, please contact us.