Leaf spring is one of the important parts of the automobile suspension system. Traditional leaf springs are made of steel materials and are used as elastic elements in different forms on different vehicles. Composite leaf springs use fiberglass-reinforced materials instead of metal materials. The mass of the manufactured component body is significantly lower than that of the metal leaf spring, which can optimize the overall structural design of the suspension, enhance safety, and achieve lightweight.

Advantages of Composite Leaf Springs:

Compared with traditional steel leaf springs, composite leaf springs have higher elasticity, stronger shock absorption, and higher vibration damping. It can effectively utilize its characteristics during vehicle driving to improve vehicle comfort and smoothness and reduce bumpiness.

In addition, the main material of this kind of spring is fiberglass composite material, which has strong fatigue resistance and the fatigue life is more than twice that of ordinary leaf springs. Composite leaf springs also contain more independent glass fibers. The load on the vehicle caused by the rupture of a single glass fiber can be freely transferred to other glass fibers to prevent damage to the load-bearing capacity of the suspension component.

Molding Process of Composite Leaf Spring and its Advantages and Disadvantages

The development process of composite leaf springs is very complex. Its production processes are divided into winding modeling, high-pressure epoxy resin transfer modeling, SMC molding, RTM process, and others.

- The winding modeling process is to pre-impregnate the glass fiber composite material, wrap it around the mold, and then go through processing methods such as mold closing and solidification to form a composite leaf spring. The advantages of winding molding are higher hardness, good fatigue characteristics, higher manufacturing efficiency, a simple process, and easy management. However, it faces major problems such as weak bonding force and easy splitting.

- High-pressure epoxy resin transfer modeling refers to using high pressure to mix epoxy resin according to the hedging risk ratio and pouring it into a vacuum-sealed mold that is pre-paved with glass fiber-reinforced materials and pre-set inserts. The mold is filled with resin flow, Impregnation, curing, and demoulding to obtain the molding process of composite products. Molding can meet the current production of leaf springs with different diameters and shapes. The products are compact and smooth in appearance, making them convenient for later industrial production.

- The SMC molding process uses traction force as the main force to solidify the impregnated glass fiber tapes and fiber fabrics through the mold to continuously manufacture composite leaf springs with different cross-section forms. The advantage of the SMC molding method is that it can continuously draw composite leaf springs of different sizes. However, it is still technically difficult to continuously manufacture leaf springs with variable cross-section structures, and the manufacturing cost is relatively high.

- The RTM process can manufacture medium-diameter width, large-variable cross-section structural leaf springs, and perform metal insert operations. However, there is deformation of the fiber layer, poor operating environment, and difficulty in meeting environmental protection standards.

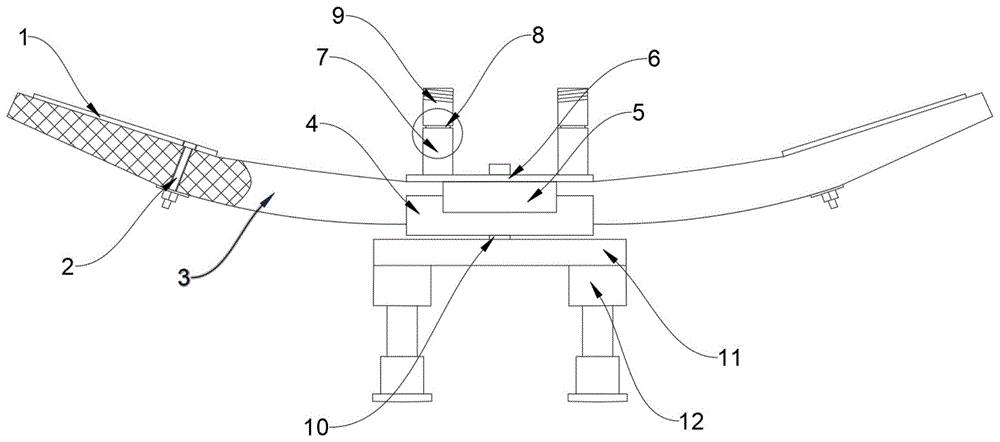

GFRP Composite Leaf Spring (glass fiber reinforced plastic leaf spring)

This composite leaf spring uses the HP-RTM (high-pressure resin transfer molding) process, using glass fiber as the reinforcing material and polyurethane (epoxy resin) as the resin matrix for mass production.

GFRP composite leaf spring manufacturing process:

- Fabric cutting: Use an automatic cutting machine to cut the fabric into pre-shaped sizes.

- Pre-shaping: The cut fabric is put into the pre-shaping mold by a robot for pre-shaping.

- Putting into the mold: Put the preshaped fabric into the forming mold through a robot.

- Injection molding: Close the mold and inject resin into the mold. Set a certain pressure and time to form and solidify with a composite material press.

- Demolding: Open the mold and eject the part. Use a robot to place it in the designated position.

- Deburring: Remove the burrs of the product.

- Machining: Place the workpiece on the tooling and process it into a specific shape through CNC.

- Inspection: Qualified products will be obtained after 100% inspection.

Advantages of GFRP composite leaf springs:

- The mass of the body is greatly reduced, and it is more than 60% lighter than the traditional steel structure leaf spring.

- Good design ability, high strength, and long fatigue life.

- Help the suspension system reduce the number of independent parts and simplify the structure and assembly process.

- One mold with multiple cavities designed for mass production.

Summarize

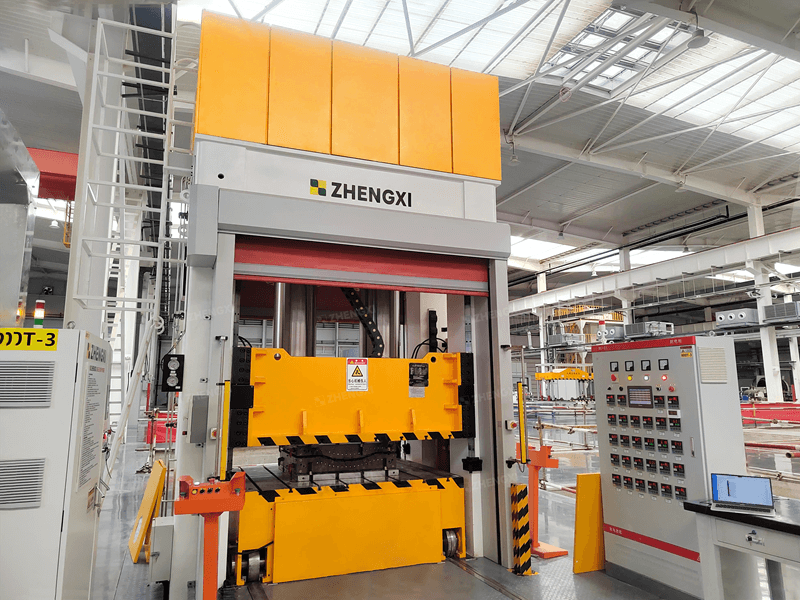

The application of composite leaf springs in car lightweight engineering will further enrich the car suspension design, better leverage the advantages of leaf springs such as high strength and large elastic strain, further improve the car suspension structure, and effectively control the impact of the external environment on the car. As a professional hydraulic press manufacturer, Zhengxi provides composite leaf springs manufacturing machines, which can help you better complete the lightweight of your vehicle.