HP-RTM stands for high-pressure resin transfer molding. It refers to the use of high-pressure pressure to mix and inject resin into a vacuum-sealed mold pre-laid with fiber reinforced materials and pre-set carbon parts. After the resin flows to fill the mold, soak, dissolve and demould, the composite material product is obtained. RTM & HP-RTM molding process is one of the composite material molding processes widely used in many industries. RTM, HP-RTM automated production line is used to produce composite structural parts with very high mechanical properties.

As a composite material molding machine supplier, Zhengxi has rich professional skills and designed an RTM & HP RTM automated press system and production line for aerospace and automotive manufacturing applications. It increases molded part productivity and improves process consistency. At present, the RTM & HP RTM production line has been gradually used in new energy vehicle parts, such as battery cases. This fully automated production line can produce 100,000 parts per year.

RTM & HP RTM Automated Production Line Equipment:

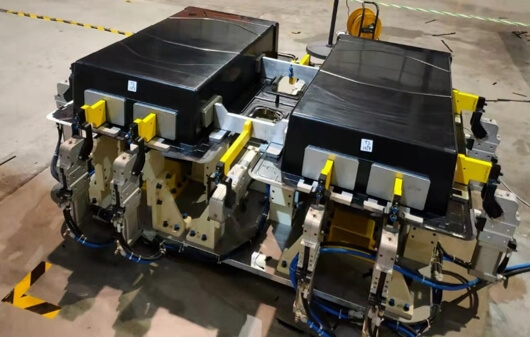

Zhengxi designs and supplies resin transfer molding (RTM) production lines equipped with automatic tool handling systems. It is characterized by versatility (with 10 different molds) and high efficiency. The RTM, HP RTM automated press systems are equipped with:

- Fiber preform processing center

- RTM injection system

- RTM hydraulic press

- Temperature Control System

- Forming mold

- Clamping and transferring equipment

- Machining equipment

- Automated mold loading and unloading system

RTM & HP-RTM process requirements for injection machines:

- High-pressure injection capability

- Injection precision control

- Communication with RTM press automation

RTM, HP-RTM process requirements for hydraulic presses:

- Tonnage to ensure clamping force

- Ensure the overall rigidity of the fuselage

- Automated integrated control of injection machines, mold temperature controllers, etc.

RTM & HP-RTM mold:

- Automatic feeding gripper

- Automated uninstall handle

- Cooling tooling

RTM, HP-RTM process requirements for mold temperature controller:

- Heating ability and temperature control ability

- Communication with RTM & HP-RTM press machine automation

Features of a Fully Automated Resin Transfer Molding (RTM) Production Line

- Mold integration

- Hydraulic pressure up to 10,000 kN

- Pressure plate size 3000 x 2000mm

- Integrated heating power unit

- Upper mobile table for mold filling with closed protective insulated injection cavity

- Automatic shuttle conveyor system

- Contact monitoring software with full traceability

Advantages of a RTM, HP RTM Automated Press Systems

- Ideal solution for automated processes

- Relatively short cycle times, which can be further optimized by gap impregnation or gap injection

- Low clock cycles and high output rates

- Parts with high-quality finish and exceptional strength

- Producing parts with high fiber content

- Repeatable and safe production processes

Zhengxi provides its customers with resin transfer molding (RTM) press lines as a one-stop solution. Our RTM and HP RTM automated press systems deliver parts of various sizes with impeccable quality. As a total integrator, Zhengxi has designed a full line with maximum efficiency to meet the highly complex requirements in composite production. Our RTM & HP RTM automated press production lines are perfectly suited to our customers’ needs. If you have any needs, please contact us immediately.