Heated Platen Press

Heated Platen Compression Molding Press

- The entry and exit dies are ground and nitriding treated with a high-precision steel structure to create a high-precision horizontal platform.

- The design structure of the machine is precise, simple, and fast. The mold is easy to match.

- With the function of slow mold calibration, mold calibration is more accurate and suitable for various molding conditions.

Video

Watch the video below to learn more details.

A heated platen press is a kind of composite material molding equipment and also the main molding equipment for silicone rubber model products and non-model products. It has the characteristics of high pressure and wide adaptability. Our heated platen presses for sale provide repeatable and precise performance, providing the uniform pressure distribution needed to produce a wide variety of laminate, wood, and composite panels, as well as molded/vulcanized rubber products.

The heated platen compression molding press machine is suitable for pressing and molding thermosetting plastics, foam, resin, bakelite, thin metal, building materials, and other model products. It is mainly used for the production of wood-based panel products such as pressed bamboo flooring, plywood, building templates, carbon fiber panels, aluminum honeycomb panels, composite material panels, insulating material panels, special cardboard, and large-format refrigerated car box panels.

1. Vulcanization process:

Multi-stage heating can be set during the heating temperature heating process. Partition temperature control, PLC control temperature to make the temperature accurate. Independent control of heating up and down. (0 to 300 degrees, special request 400 degrees)

2. Pressurization process:

During the pressurization process, multi-stage pressurization can be set, and the pressure is controlled by PLC to make the temperature and pressure accurate.

The Advantages of Hydraulic Platen Press

Hot platen:

Made of high-quality carbon solid steel plate, with high precision, high strength, and durability.

Customize the size of the worktable to allow users to achieve convenient and comfortable operation.

Heating system:

Carefully segmented design, low energy consumption, uniform heat conduction, adjustable temperature.

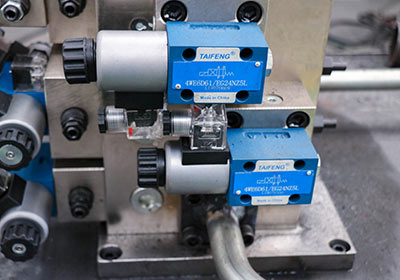

Hydraulic system:

The main hydraulic components are imported and the pressure can be adjusted.

Cylinder:

It is processed by precision numerical control and adopts an imported oil seal without oil leakage.

Automatic control:

Just press a button to complete the whole set of procedures such as platen rising, closing, pressurizing, holding pressure, timing, and platen descending.

Equipment Customization Scope

- Temperature control customization range: -40C~400C

- Equipment structure: H-frame type, four-column type, gantry type, box type, lamination type. Heating method: hot plate, hot box (1, electric heating and water cooling, 2, heat conduction oil heating and cooling).

- Forming methods: constant pressure forming, fixed stroke forming, pressure and temperature ramp control forming, and pressure and temperature curve control forming.

- Other optional functions: data recording (exportable and printable), auxiliary workbench, high-pressure injection system, and automatic mold opening mechanism.

- The heated platen press for sale is a combination of the Four-column or H-frame structure and is equipped with hot plates and a heating device to realize pressure under high and low-temperature conditions.

- Eight-sided guide structure, larger guide area, strong anti-eccentric load capacity.

- Multi-cylinder evenly distributed structure, heightened beam design, stronger molding stability.

- The hydraulic system is installed on the top of the machine, and equipped with a maintenance platform, which is environmentally friendly, has low noise, and is easy to maintain.

- ≥500mm/s fast mold clamping. It can be divided into multi-stage slow pressure molding, a reasonable time reserved for exhaust.

- High-pressure slow mold opening function, suitable for higher products.

- The quick response of the servo system, full digital control, and energy saving of oil pump power by 40%-80%.

- Microcomputer closed-loop heating control system, the temperature control can reach ±2°C, and mold heating can save more than 10% of electricity.

- Optional: exhaust gas purification system, mold changing trolley, remote after-sales service system, double closed-loop servo system.

- With a double closed-loop servo system, the pressure control accuracy can reach ±0.05Mpa. And the position control accuracy can reach ±0.01mm.

- Press pressure: 160 tons, 500 tons, 800 tons, 1000 tons, 1200 tons, 3000 tons, etc.

- Hot plate specifications: 1300*2500mm, 1400*2600mm, 2000*8000mm, 3000*16000mm, etc. (determined by the user’s product)

- The number of layers: single layer, 3 layers, 5 layers, 10 layers, 15 layers, 20 layers, etc.

- Number of hot plates: 2 pieces

- Hot plate spacing: 80mm, 100mm, 250mm.

- Nominal clamping force: 1.00MN/2.00MN/3.00MN/4.00MN/5.00MN

- (can be made according to user requirements)

- Heating method: electric heating/heat conduction oil (choose one of the two)

- Heating temperature: 0-300°C (customized according to user requirements)

- Control mode: PLC automatic control

Heated platen compression molding press is mainly used for integral molding of thermosetting (glass-reinforced plastic) plastic products and thermoplastic products. And it is suitable for molding various groups and sheets such as SMC, BMC, DMC, and GMT.

The heated platen hydraulic press is suitable for furniture factories, door factories, and wood-based panel secondary processing (professional veneer) factories. It is used for thermocompression bonding of furniture panels, building partitions, wooden doors, etc.

All kinds of wood-based panels: plywood, blockboard, MDF, particle board surface pressing

Various decorative materials: decorative cloth, stickers, veneer, PVC, etc.

It can also be used for drying and leveling veneers, and the leveling and shaping of colored decorative wood chips with remarkable effects.