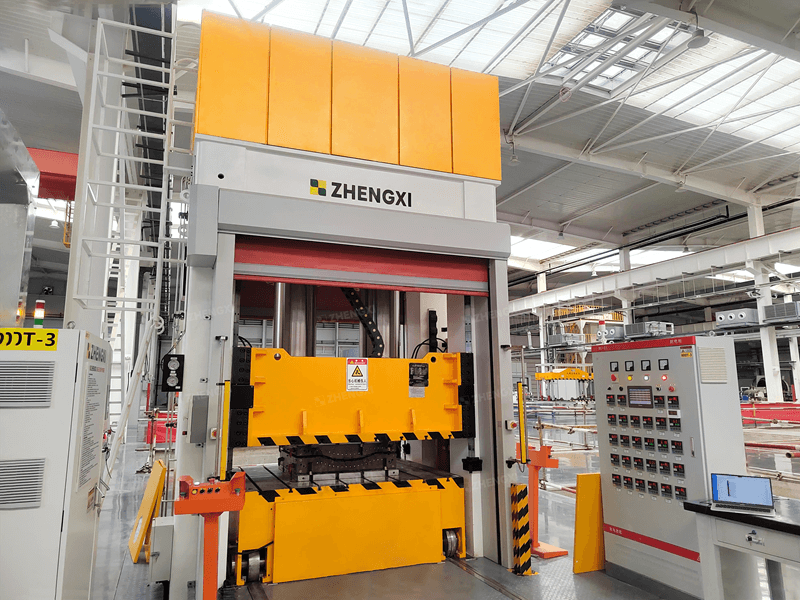

Truck chassis are also called car beams and car bottom beams. Together with the car’s cross beam, it forms a key part of the car’s load-bearing capacity. Usually stamped from low alloy steel plate. Depending on the car model, there are many specifications and sizes of automobile longitudinal and cross members. If you want to press and shape large longitudinal and cross beams at one time, you need to use high-quality truck chassis stamping equipment. It is recommended to choose our 2000T truck chassis hydraulic press.

The truck chassis press is mainly suitable for the pressing, punching, and blanking processes of large automobile bottom beams. It can also be used for the pressing, bending, and forming of other metal materials. The main components of this series of hydraulic presses include a hydraulic press host, mobile workbench, hydraulic transmission system, lubrication system, electrical control system, and other auxiliary devices. There are auxiliary automatic loading and unloading devices to cooperate with the work. The automatic forming process of truck chassis can be realized.

Working Conditions of Truck Chassis Press

1) Ambient temperature: -5℃~50℃

2) Relative humidity: ≤85%, No condensation

3) Running Ability: Support 24-hour continuous production

4) Power supply: AC323-528V, 50HZ TN-S

5) Air Supply: Dg15mm, 0.4~0.6Mpa

6) Water Supply: Water Pressure 0.2~0.3Mpa, Cooling Water≤28℃, CL of cooling water<25ppm.

Features of Truck Chassis Hydraulic Press:

- It is used in the stretching process of automobile longitudinal beams, and can also be used in other metal sheet pressing, forming, and correction processes.

- It has an independent power mechanism and electrical system. Using PCL technology, closed-loop synchronous control system button centralized control. It can realize three operation modes: inching, manual, and semi-automatic, and adopts different program controls according to the length of the user’s product to reduce power consumption.

- The working pressure, pressing speed, and stroke range of this machine can be adjusted according to process requirements.

- The press machine is designed as an assembled H-frame which has the best system rigidity, high precision, long lifetime, and high reliability, and is used for pressing sheet metal parts and can meet the demand of production at 3 shifts/ day.

- The hydraulic system adopts an integrated cartridge system combined with a proportional control valve. It can meet the requirements of a large flow rate, high synchronization accuracy, and large anti-eccentric load capability. The structure is simple and compact, and the action is sensitive and reliable, making it easy to diagnose and eliminate faults.

- The power system is installed in the upper position to reduce the machine’s floor space. There are safety guardrails around the upper beam and spare ladders to facilitate installation and maintenance.

- The eccentric load is large during the forming process of the longitudinal beam. A slider intelligent balancing system is adopted to ensure parallelism during the pressing process. It is composed of multiple hydraulic pads and adopts hydraulic pad automatic synchronization technology. Ensure that the movements of each hydraulic pad are synchronized during the forming and ejection of longitudinal beams.

- Intelligent frequency conversion control technology is adopted to achieve step-less control of loading and unloading speed. Through Ethernet connection technology and PLC control technology, the position, speed, and production rhythm of loading and unloading can be reasonably matched, thereby improving production efficiency.

Application of Truck Chassis Press

The truck chassis hydraulic press machine is mainly suitable for sheet metal part processes such as stretching, bending, crimping, forming, blanking, punching, correction, etc., and is mainly used for quick stretching and forming of sheet metal.

Technical Parameters of Truck Chassis Hydraulic Press:

| Name | Unit | Value |

| Name of machine | Hydraulic press | |

| Model | Yz27-2000T/900T | |

| Main cylinder pressure | KN | 2000 |

| Die Cushion force | KN | 9000 |

| Max. liquid pressure | MPa | 25 |

| Daylight | mm | 2000 |

| Main cylinder Stroke | mm | 1500 |

| Die Cushion Stroke | mm | 400 |

| Worktable size – LR | mm | 7000 |

| Worktable size – FB | mm | 1800 |

| Die cushion size | mm | 6440 |

| FB | mm | 1270 |

| Slider speed – Down | mm/s | 300 |

| Slider speed – Return | mm/s | 150 |

| Slider speed – Working | mm/s | 10-16 |

| Ejection speed – Ejection | mm/s | 80 |

| Ejection speed -Return | mm/s | 50 |

| Worktable moving distance | mm | 7000 |

| Position accuracy | mm | <0.1 |

| Servo motor | Kw | 160 |

| Pressure control accuracy | Mpa | <0.4 |

| Weight of machine | T | 350 |

Details of Truck Chassis Press

1. Main Body

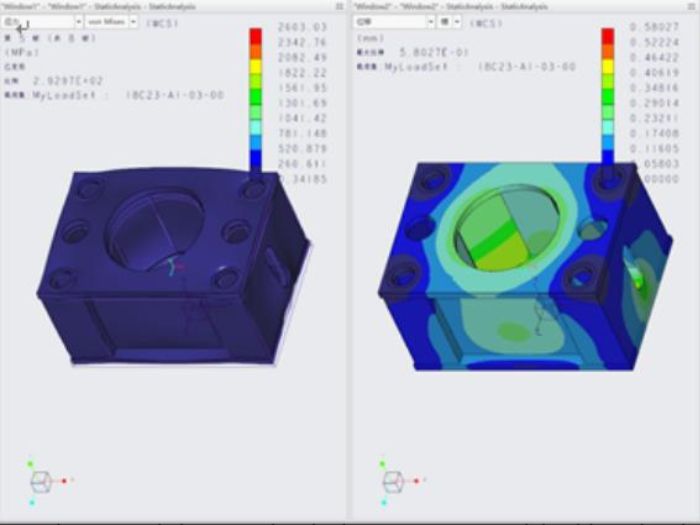

The design of the whole machine adopts computer optimization design and analyzes with finite elements. The strength and rigidity of the equipment are good, and the appearance is good. All welded parts of the machine body are welded by high-quality steel mill Q345B steel plate, which is welded with carbon dioxide to ensure the welding quality.

2. Cylinder

| Parts | Feature |

| Cylinder Barrel | 1. Made of 45# forged steel, quenching and tempering. 2. Fine grinding after rolling. |

| Piston Rod | 1. Made by chilled cast iron, quenching and tempering. 2. The surface is rolled and then chrome-plated to ensure surface hardness above HRC48~55.3. Roughness 0.8. |

| Seals | Adopt Japanese NOK brand quality sealing ring |

| Piston | Guided by copper plating, good wear resistance, ensures long-term operation of the cylinder. |

3. Pillar

The guide columns (pillars) will be made of C45 hot-forging steel. The guide sleeve adopts a copper guide sleeve, and the slide guiding system is an 8-point gib guiding system with replaceable phosphorus bronze linear.

4. Platen

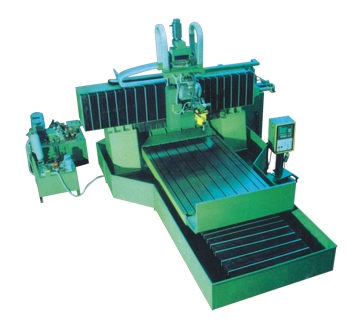

The platen of this machine is welded by a Q345B steel plate. The whole machine is heat treated to reduce welding stress and improve the stability of the machine. The platen surface is processed by a large grinder, which can confirm the good flatness.

5. Servo System

The main cylinder upper chamber is equipped with a pressure sensor. The slide is equipped with a displacement sensor controller. The truck chassis press adopts PID to adjust the pressure and position, through the speed of the servo motor to precede the closed-loop control. By adjusting the speed of the servo motor, it can control the pressure, speed, position, and other parameters of the hydraulic press.

6. Hydraulic System

- The oil tank has been set forced cooling filtering system to make sure the machine can steadily press in 24 hours.

- The hydraulic system adopts an integrated cartridge valve control system with fast response speed and high transmission efficiency.

- The oil tank is equipped with an air filter to ensure that the hydraulic oil is not polluted.

- The connection between the filling valve and the fuel tank uses a flexible joint to prevent vibration from being transmitted to the fuel tank and completely solve the problem of oil leakage.

- The hydraulic oil pipe is mainly made of seamless steel pipe, and the large diameter oil path is flanged. The pipe connection is connected by SAE flange as much as possible. It is a butt welding type with good welding effect and effectively solves the oil leakage problem caused by poor welding.

7. Electrical control system

- The control circuit system adopts a PLC programmable controller combined with a touch screen main control to realize various process action cycles of the machine tool.

- The core function of the control part is assumed by the “PLC” programmable logic controller. According to the needs of the process, the commands issued by the main control components (selection switches, buttons, etc.), are based on the signals measured by the detection elements such as displacement sensors, travel switches, pressure sensors, etc.

- The stroke of the slider is controlled by an absolute displacement sensor. The stroke and position conversion points can be directly set and displayed on the touch screen.

As a professional hydraulic press factory in China, zhengxi provides high-quality truck chassis presses. Besides, we also provide FRP tank-making machines, FRP manhole cover-making machines, composite hydraulic presses, metal forming machines, forging presses, and so on.