The composite resin drainage ditch cover adopts advanced technology and is formed by high-performance SMC sheet material after high-temperature molding. It is a kind of composite manhole cover. It is made of glass fiber and resin with SMC hydraulic press.

The composite resin drainage ditch cover has the advantages of high impact strength, low price, lightweight, and good anti-corrosion performance. It is widely used in municipal engineering, construction engineering, public engineering, gardens, and other places and areas that require ground and road drainage and drainage.

Performance Characteristics of Composite Drainage Ditch Cover

1. Preservative

Composite drainage ditch cover has very superior acid resistance, alkali resistance, resistance to organic solvents and salts, and many other gas and liquid media corrosion performance. It has incomparable superiority in the field of anti-corrosion. According to the requirements of actual use occasions, o-phthalic, isophthalic, and vinyl resins can be economically selected as matrix materials.

2. Lightweight, high strength, and easy to cut and install

Because it is made of resin and glass fiber, its density is small, only 1/4 of steel and 2/3 of aluminum. Its strength is 10 times that of rigid polyvinyl chloride. The absolute strength exceeds the level of aluminum and ordinary steel. Its lightweight can greatly reduce the foundation support, thereby reducing the material cost of the project.

The cutting and installation of the composite drainage ditch cover are simple, no large-scale lifting equipment is required, and only a small amount of labor and electric tools are required. This leads to a significant reduction in installation costs as well.

3. Aging resistance

In theory, the service life is more than 20 years.

4. Safety

The special structure of the composite drain cover also has the characteristics of anti-slip and anti-fatigue.

5. Color

Color can be chosen arbitrarily. Colors can be customized according to customer requirements to improve the environment of the production site.

6. Strong designability

The size is flexible and diverse, easy to cut, and stable in size.

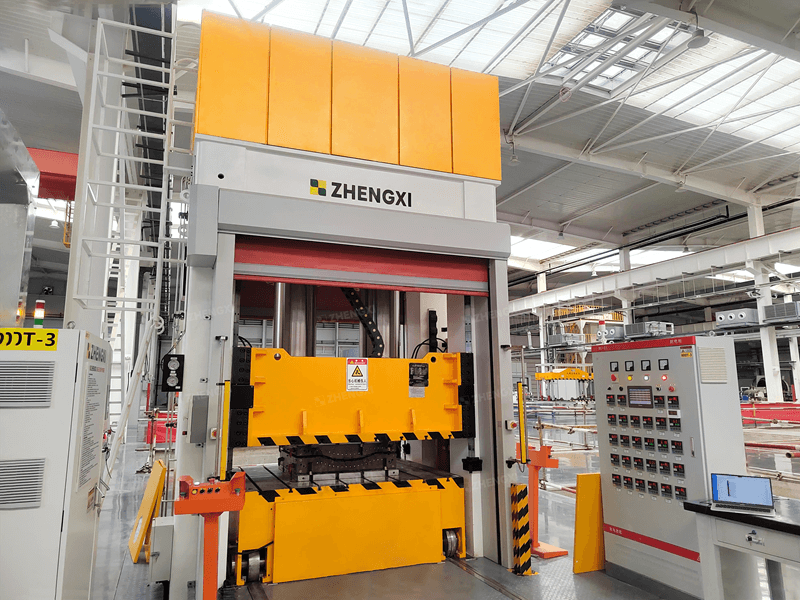

Composite Resin Drainage Ditch Cover Forming Hydraulic Press

According to Zhengxi’s experience in designing and manufacturing composite drain cover forming hydraulic presses, we recommended that customers use 315-ton, 400-ton, 500-ton, and 630-ton four-column hydraulic presses. The equipment can also be used to press BMC grate, tree pool cover, plastic manhole cover, trench cover, farm ditch cover, car wash cover, and other products.

The composite resin drain cover hydraulic press has a four-column structure, which is economical and practical, and has high pressing precision. It has an independent hydraulic pump station and electrical control system. The hydraulic control adopts a cartridge valve integrated system, which has a compact structure, reliable action, good sealing performance, long service life, and convenient installation and maintenance.

The oil pressure is displayed by a digital display electric contact pressure gauge, and the upper limit of the oil pressure can be set arbitrarily within the allowable range as required. The electrical system adopts button centralized control and has two operation modes of inching and semi-automatic. The working pressure and stroke can be adjusted arbitrarily within the specified range according to the needs, and two molding methods of constant pressure and fixed stroke can be completed.

Advantages of resin drain cover molding

① High production efficiency, easy to realize specialized and automatic production.

②The product has high dimensional accuracy and good repeatability.

③Smooth surface, no need for secondary modification.

④ It can form products with complex structures at one time.

⑤ Due to mass production, the price is relatively low.

All composite drain cover hydraulic presses can be added with the following optional configurations according to user requirements:

A. Mobile workbench

B. Foot switch or handle

C. PLC electrical control system

D. Industrial touchscreen

E. Grating protection device

F. Safety protection device

G. Stroke and pressure digital display device

H, upper and lower heating plates

I. Hydraulic system cooling device

J. Electro-hydraulic servo system

The key factors of thermoforming resin drain cover are mastering the required pressure, speed, time, and so on. The SMC hydraulic press designed and produced by Zhengxi is specially used to produce composite resin drain covers. It has the function of holding pressure and delaying time, and the delay time is adjustable. And the pressure, speed, and stroke required by the machine and equipment during work can be adjusted according to demand.

Customers can change the mold to complete the compression molding of resin drainage ditch covers with different structural styles. One machine with multiple functions reduces the investment cost of customers. Therefore, our SMC hydraulic presses are the first choice of many gutter cover manufacturers. Contact us for more information about hydraulic presses.