Forged flange is a product with the best mechanical properties among flanges. Its raw material is generally a tube blank. After cutting, the hammer or the die of the forging machine is used to apply pressure on the blank to cause plastic deformation. Thus obtaining the desired shape and size.

Flange forgings are formed by forging and pressing after the metal is heated in the solid state. It requires the metal to have good thermoplasticity (also called forgeability). Generally, forgings are steel parts. It has high strength and good plasticity and is suitable for manufacturing important parts with high stress and high requirements, such as bolts, shafts, Gears, etc.

The forged flange is not easy to rust. The forging has a good streamlined shape, the structure is relatively dense, and the mechanical properties are good. Forged flanges can withstand higher shear and tensile forces.

1. Flange Forging Production Process

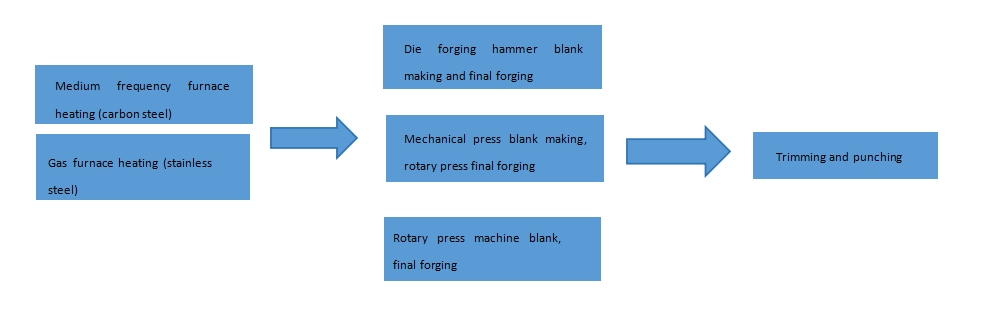

(1) Small flange production process

Small flange, directly forged, with high production efficiency. Open or closed forging processes can be used. When forging small flanges, medium-frequency induction furnace heating can be used. For stainless steel materials, due to the low efficiency of the intermediate frequency heating furnace, other heating methods can be used. Forging is divided into two steps, pre-forging and final forging. This can be done on a hammer or screw press, or the billet-making process can be done on another piece of equipment. Trimming and punching after final forging.

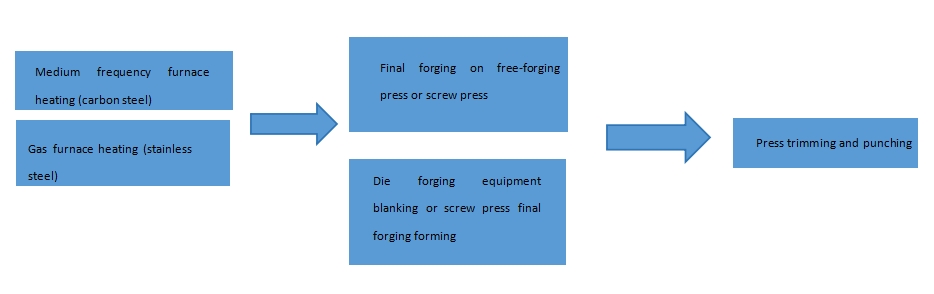

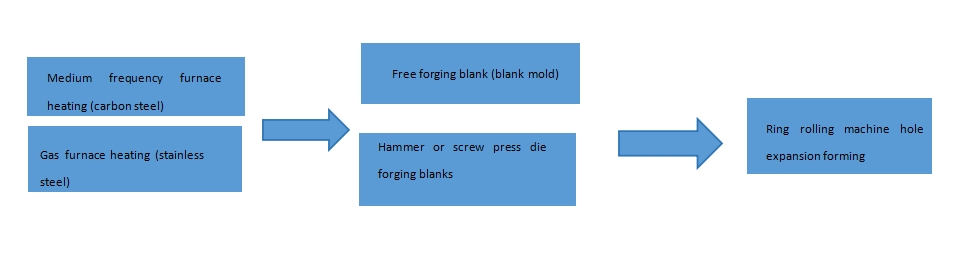

(2) Medium flange production process

Medium-sized flange can be directly forged or rolled after forging. According to the weight and material of the flange, select a suitable furnace type for heating and direct die forging. There are also pre-forging and final forging, which can be completed on different equipment. Pre-forging can be free forging or die forging, and final forging generally uses a hammer or hydraulic press. The medium-sized flange is rolled and formed, and the blank can be made by die forging on a large forging hammer or screw press. After the blank is rolled, it is rolled into shape.

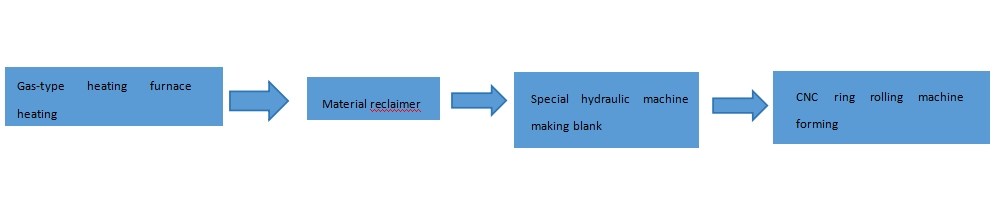

(3) Large flange production line

The large-scale flange production line is composed of a special blank-making hydraulic press, a CNC ring rolling machine, and a reclaimer. For heating of large flanges, chamber forging furnaces or trolley forging furnaces are usually used. The reclaimer places the material on a special hydraulic forging press to complete upsetting and punching. Rolled to shape on CNC ring rolling machine.

2. Flange Forging Process Block Diagram

(1) Small flange

(2) Medium flange

Direct die forging process

Rolling and expansion process

(3) Large flange

3. Analysis of Flange Forging Process

Small flanges are in high demand and can be produced automatically. When assembling the flange production line, use a mechanical press or an electric screw press to make the blank. Electric screw press for final forging. Mechanical press trimming and punching.

When the medium-sized flange is made from a free-forging mold, the operator requires high professional skills and the labor intensity is high. The large flange blanking hydraulic press is a special equipment that completes the upsetting, punching, and preforming processes on one piece of equipment. CNC ring rolling machine has good precision and high efficiency.