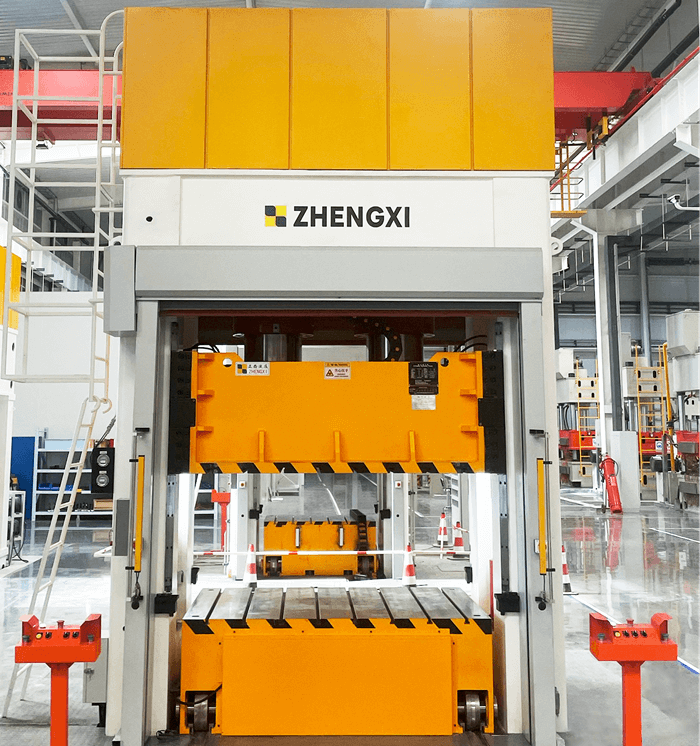

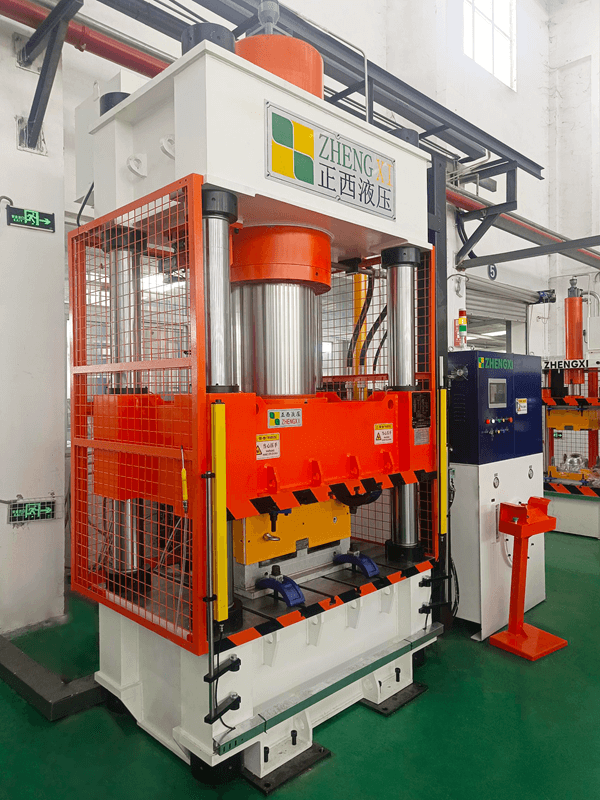

FRP molding hydraulic press is suitable for processing a variety of composite materials and fiber-reinforced materials. Its core advantage is to achieve full flow and solidification of materials through high temperature and high pressure to form high-strength and lightweight products. The following is a description of the specific applicable material classification and characteristics:

Thermosetting Resin-based Composite Materials

1. SMC (sheet molding compound)

◆ Features: It is pre-mixed with unsaturated polyester resin, glass fiber, filler, etc. into sheets with good fluidity, suitable for complex structural parts.

◆ Application: car bumpers, instrument panels, sanitary ware, electrical housings, etc.

◆ Molding advantages: The high pressure of the hydraulic press can quickly remove bubbles and ensure the product’s density.

2. BMC (bulk molding compound)

◆ Features: high resin content, short fibers, suitable for small precision parts.

◆ Application: circuit breaker housing, junction box, electrical switch, valve components, etc.

◆ Molding advantages: The hydraulic press can accurately control pressure and temperature to avoid material scorching.

3. DMC (bulk molding compound, similar to BMC)

◆ Features: Similar to BMC composition, but slightly lower fluidity, suitable for high-strength requirements.

◆ Applications: aviation interior parts, rail transit parts, corrosion-resistant pipe joints, etc.

Thermoplastic Composite Materials

1. GMT (glass fiber mat reinforced thermoplastics)

◆ Features: It is a composite of thermoplastic resin (such as PP, PA) and glass fiber mat, which can be recycled.

◆ Applications: car seat frames, luggage racks, logistics pallets, sports equipment, etc.

◆ Molding advantages: The hydraulic press quickly heats the material to soften it, and it can be rapidly molded, which is suitable for mass production.

2. LFT (long fiber reinforced thermoplastics)

◆ Features: The fiber length can reach 10-50mm, and the mechanical properties are excellent.

◆ Applications: new energy vehicle battery box, front frame, chassis guard plate, etc.

◆ Molding advantages: The high pressure of the hydraulic press can ensure uniform distribution of fibers and reduce product warping.

Fiber-reinforced Materials

1. Glass fiber reinforced materials

◆ Types: chopped fibers, continuous fibers, mats, etc.

◆ Applications: building formwork, ship decks, wind turbine blade components, etc.

◆ Molding advantages: The hydraulic press can realize the compaction and solidification of multiple layers of fibers, and improve the interlayer strength of the product.

2. Carbon fiber reinforced materials

◆ Features: high strength, low density, suitable for high-end fields.

◆ Applications: aerospace structural parts, high-end sports equipment (such as bicycle frames, golf clubs), lightweight automotive parts, etc.

◆ Molding advantages: The high-precision control of the hydraulic press can avoid carbon fiber damage and ensure product performance.

Other Composite Materials

1. Basalt fiber composite materials

◆ Features: high temperature resistance, corrosion resistance, higher cost performance than carbon fiber.

◆ Application: fire fighting equipment, chemical pipelines, high temperature insulation boards, etc.

◆ Molding advantages: hydraulic presses can adapt to the high modulus characteristics of basalt fiber and ensure the dimensional stability of products.

2. Natural fiber composite materials

◆ Types: flax fiber, sisal fiber, bamboo fiber, etc.

◆ Application: automotive interior parts (such as door panels, ceilings), environmentally friendly packaging materials, etc.

◆ Molding advantages: hydraulic presses can achieve low-temperature molding to avoid thermal degradation of natural fibers.

Material Selection and Hydraulic Press Adaptability

1. Fluidity matching:

◆ High-fluidity materials (such as SMC) are suitable for rapid molding, and hydraulic presses must have rapid mold closing and exhaust functions.

◆ Low-fluidity materials (such as LFT) require high pressure and long-term pressure maintenance, and hydraulic presses must be equipped with high-precision pressure control systems.

2. Adaptation of curing characteristics

◆ Thermosetting materials (such as SMC, BMC) require precise temperature and time control, and the hydraulic press needs to integrate a temperature control system.

◆ Thermoplastic materials (such as GMT, LFT) require rapid heating and cooling, and the hydraulic press needs to be equipped with efficient heating plates and cooling channels.

3. Fiber content and length

◆ High-fiber content materials require high-pressure compaction, and the hydraulic press must have a high tonnage (more than 500 tons).

◆ Long-fiber materials must avoid fiber breakage, and the hydraulic press must adopt a low-speed mold closing and pressure holding process.

Summary

The FRP forming hydraulic press is suitable for processing various composite and fiber-reinforced materials. Its core lies in achieving full flow, compaction, and solidification of materials through high pressure and precise control of the hydraulic system. When selecting materials, factors such as fluidity, solidification characteristics, fiber content, and length should be considered comprehensively, and the tonnage, temperature control, mold closing speed, and other parameters of the hydraulic press should be matched. With the widespread application of composite materials in automobiles, aerospace, new energy, etc., the technical requirements of FRP forming hydraulic presses will continue to increase, driving the industry to develop with high efficiency, precision, and greenness. If you have any needs, please contact us.