Carbon fiber is the most important inorganic high-performance fiber. This is determined by factors such as the nature of its materials, the complexity of industrial technology, the importance of application fields, and the scale of the market.

The most important form of application of carbon fiber is as a reinforcement of resin materials. The formed carbon fiber reinforced plastic (CFRP) has excellent comprehensive properties. It is used in missiles, space platforms and launch vehicles, aircraft, advanced ships, rail vehicles, electric vehicles, trucks, wind turbine blades, fuel cells, power cables, pressure vessels, uranium enrichment ultra-high-speed centrifuges, special tubes, public foundations Sixteen fields, including facilities, medical and industrial equipment, sports and leisure products, and fashion and living appliances, have practical and potential applications.

The application of carbon fiber reinforced polymer in the above fields and its recent technical progress will be reviewed below.

1. CFRP As a Key Material for Missiles, Space Platforms, and Launch Vehicles

Carbon fiber is the material basis of the modern aerospace industry and is irreplaceable. CFRP is widely used in aerospace fields such as missile weapons, space platforms, and launch vehicles. In the application of missile weapons, CFRP is mainly used to manufacture primary and secondary load-bearing structural components such as missile fairings, composite brackets, instrument cabins, bait cabins, and launch tubes.

In terms of space platform applications, CFRP can ensure small structural deformation, good bearing capacity, radiation resistance, aging resistance, and good space environment tolerance. It is mainly used to manufacture structural components such as bearing tubes, honeycomb panels, substrates, camera barrels, and parabolic antennas of satellites and space stations.

In terms of launch vehicle applications, CFRP is mainly used to manufacture rocket body fairings, instrument compartments, shells, interstage sections, engine throat liners and nozzles, and other components.

At present, the application of CFRP on spacecraft has matured day by day. It is an indispensable key material to realize the lightweight, miniaturization, and high performance of spacecraft.

2. CFRP As a Structural Material for Aircraft

In large advanced aircraft, CFRP is widely used as the main load-bearing structural material. And in the recently developed new airship, CFRP is also used as a structural material.

Modern aircraft fuselages are made of steel, aluminum, titanium, and other metals and composite materials. In order to save fuel and improve operating efficiency, reducing the weight of the fuselage has always been one of the core challenges in aircraft design and manufacturing technology.

The mature application of CFRP in the manufacture of aircraft fuselage provides the most effective way to reduce the quality of aircraft fuselage. For example, the fuselage mass of the Boeing 767 aircraft mainly made of metal materials (the amount of CFRP only accounts for 3%) is 60 t, and when the amount of CFRP is increased to 50%, the mass of the new Boeing 767 aircraft fuselage drops to 48 t. This alone greatly enhances the aircraft’s energy and environmental efficiency.

3. CFRP As an Advanced Ship Hull Structure

CFRP is very obvious to improve the ship’s structure, energy consumption, and maneuverability. CFRP technology is mainly used in the development of military ships. The hull adopts a CFRP sandwich structure, which has excellent performances such as high strength, high hardness, low mass, impact resistance, low radar and magnetic field signals, and electromagnetic wave absorption.

CFRP has also been used in the manufacture of ship propeller blades, integrated masts, and advanced surface ship superstructures.

Low noise and quiet operation is a core technology in the field of military ships and a key indicator of the performance of ships (especially submarines). Because when the propeller is running at high speed, there will be cavitation bubbles on the propeller blades, which will lead to the erosion of the propeller blades, accompanied by strong vibration and noise. CFRP blades are not only lighter and thinner, but also improve cavitation performance, reduce vibration and underwater characteristics, and reduce fuel consumption.

4. CFRP As the Body Structure of Rail Transit Vehicles

Lightweight is a key technology to reduce the energy consumption of train operations.

CFRP is the focus of material selection for the new generation of high-speed rail train bodies. It can not only reduce the weight of the rail train body, but also improve high-speed running performance, reduce energy consumption, reduce environmental pollution, and enhance safety. At present, the application trend of CFRP in the field of rail vehicles: from non-load-bearing structural parts such as car interiors and in-vehicle equipment to load-bearing components such as car bodies and frames; vehicle body, and other large-scale structural development. Based on the hybrid structure of metal and composite materials, the amount of CFRP has increased significantly.

5. CFRP As the Body Structure of Electric Vehicles

Research on the reduction of vehicle weight and production costs by materials shows that for every 10% reduction in vehicle mass, fuel consumption can be reduced by 6%. Among existing materials, CFRP has the best lightweight effect. The CFRP body has extremely high compressive strength and can withstand faster acceleration. And the agility and road feel of the vehicle is very good.

6. CFRP As Reinforcement Structure for Wind Turbine Blades

In order to improve the wind energy conversion efficiency of wind turbines, increasing the unit capacity and reducing the unit kilowatt mass are the key. Wind turbine blades are the key components for effectively capturing wind energy in wind turbines, and the length of the blades continues to increase with the increase in the capacity of a single wind turbine.

The increase in impeller diameter puts forward lighter and higher requirements on the quality and tensile strength of the blade. CFRP is a key material for manufacturing large blades, which can make up for the lack of performance of glass fiber composite materials (GFRP).

7. CFRP As the Core Material of Power Cables

There are serious line loss problems during the transmission of electric energy from the power plant to the power consumption site. Line loss refers to the power loss generated in power transmission links such as power transmission, power transformation, and power distribution.

The strength of CFRP aluminum core conductor is twice that of steel core aluminum conductor of the same quality. The transmitted current capacity is twice that of other core aluminum conductors. The line loss is 25%~40% lower than that of other core aluminum conductors. Its performance of high capacity, high efficiency and low sag far surpasses that of aluminum core conductors made of other materials.

8. CFRP As a Reinforcement Material for Special Tubes

Different from the long-term continuous pressure resistance of pressure vessels, special barrels such as gun barrels, gun barrels, and hydraulic cylinders need to withstand and release high pressure frequently for a long period of time. Such special-purpose pressure-bearing tubes reinforced by carbon fiber winding or prepreg coating have obvious effects in reducing their own weight, improving heat dissipation, improving precision, and extending life.

The successful application of CFRP technology on the barrel was soon extended to the reinforcement of various barrels. At the same time, special hydraulic actuators reinforced with CFRP are also available on the market.

9. CFRP As a Key Material for Public Infrastructure Construction

Bridges are important transportation infrastructure. In the construction of large-scale traffic channels across rivers and straits, many long-span bridges need to be built. The mass stress percentage of the CFRP main cable itself is greatly reduced, and the live load stress percentage is increased to 13% (the steel main cable is 7%). And the vertical bending, transverse bending, and torsional fundamental frequencies of the structure are greatly increased.

The increase in the safety factor of the CFRP main cable will improve the vertical and torsional stiffness of the structure. Increasing the elastic modulus of the CFRP main cable can greatly reduce the vertical deflection of the live load and increase the fundamental frequency of vertical bending and torsion. In conclusion, CFRP main cables can significantly improve the overall performance of long-span suspension bridges.

In addition, the fields of architecture and civil engineering were the first to use carbon fiber for structural reinforcement. By covering bridges and other buildings with carbon fiber fabrics, the durability of cement structures and the seismic performance of cement structures can be improved.

In the future, CFRP is likely to become a veritable building material. Countries around the world are speeding up technology development so that CFRP can be directly used as building structural materials. For example, use the conductivity of CFRP to make electromagnetic protection materials for buildings; embed sensors in CFRP to make smart building materials, and use the data transmitted by the sensors to grasp the possible damage to the building structure in real-time.

10. Application of CFRP in the Fields of Medical Devices and Industrial Equipment

In the field of medical equipment, it is used to manufacture mobile platforms for X-ray inspection machines by taking advantage of its total X-ray transmission. Utilizing the excellent mechanical properties of CFRP, it is used in the manufacture of medical devices such as orthopedics and organ transplantation, as well as rehabilitation products such as prosthetics and orthotics.

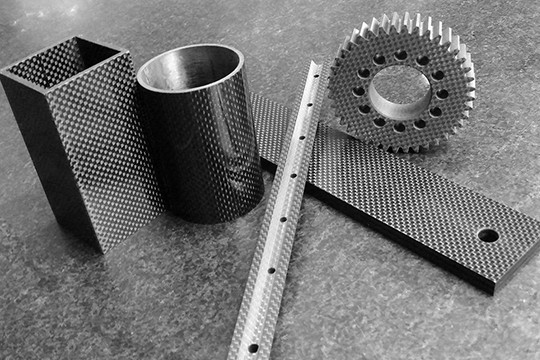

CFRP parts molded from chopped carbon fiber and nylon or polycarbonate with a mass fraction of 10% to 60% are light in weight, thin in thickness, anti-static and anti-electromagnetic, and are used in electronic information products such as notebook computers, LCD projectors, It is widely used in cameras, optical lenses, and large liquid crystal display panels. In addition, CFRP has excellent tear resistance, and can also be used to manufacture bearings, rollers, pipes, and other products. Its strength is the same as that of steel products, but its quality can be greatly reduced.

11. Application of CFRP in the Field of Sports and Leisure Products

Sports and leisure products are the earliest application fields for CFRP to enter the market. With the improvement of cost performance, this field has formed a stable demand for CFRP. Skis, ski poles, ice hockey sticks, tennis rackets, and bicycles are typical applications of CFRP in sports and leisure products.

12. Carbon Fiber as Fashion Element Material

The black and bright color of carbon fiber itself, as well as the texture, direction, and texture of its woven fabric and windings, provide fashion designers with rich imagination space and styling elements.

At present, clothing accessories made of carbon fiber include shoes, hats, belts, jewelry, wallets (clips), glasses frames, etc., travel supplies include luggage, etc., and household appliances include tables, chairs, bathtubs, etc. All these products show the cool, tough, proud, and elegant fashion characteristics of carbon fiber. They are both daily necessities and works of art, adding the ultimate luxury technology and artistic enjoyment to people’s life.

In summary, carbon fiber has a wide range of applications in many fields. The continuous subdivision of the application market will also promote the differentiated development of carbon fiber technology, and more and better carbon fiber products will be manufactured to promote the green development of society and meet people’s diverse life needs.

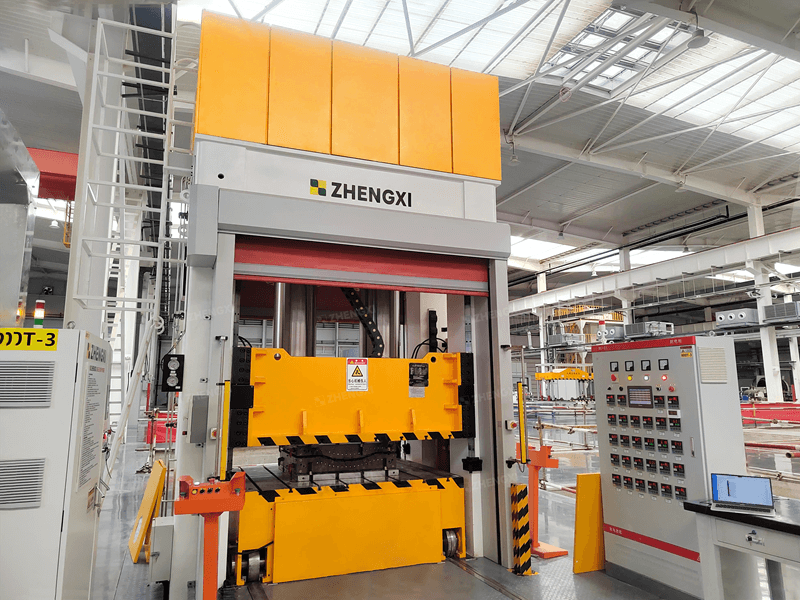

Zhengxi is a professional hydraulic press factory in China, that provides high-quality carbon fiber presses which form carbon fiber reinforced plastic products.