A new energy battery shell forming hydraulic press is key manufacturing equipment used to produce battery casings required for electric vehicles, energy storage systems, and other new energy applications. These shell-forming hydraulic presses play a vital role in the new energy industry. Their performance characteristics, advantages, and application areas will be introduced below.

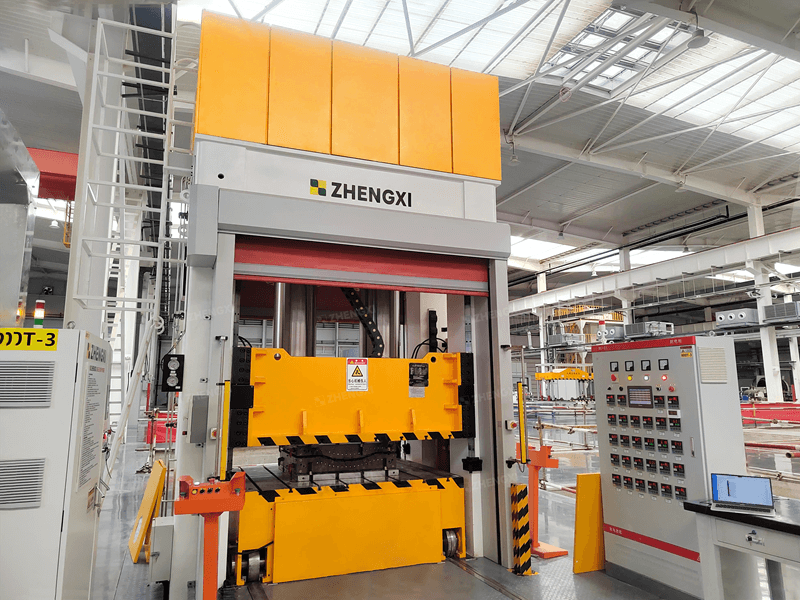

The 1250-ton hydraulic press is a new energy battery casing forming hydraulic press customized by Zhengxi Hydraulic according to customer needs. The equipment adopts a frame structure, which has good rigidity, high precision, and strong anti-eccentric load ability. Adopting a servo control system, it is efficient and energy-saving. Pressure and speed are adjustable.

The 1250-ton hydraulic press for stamping new energy battery shell adopts advanced joint technology and has a large upper and lower movement space, which facilitates the suppression of workpieces. The working pressure can be preset, and the slider guide is a rectangular guide rail with four corners and eight sides. The surface is high-frequency quenched, with high precision and adjustable gap. The friction pair of the guide rail is made of high-quality tin bronze alloy, which is more wear-resistant and has better accuracy maintenance.

Technical Parameters of 1250-ton Battery Shell Forming Hydraulic Press:

- Equipment model: YQ34-1250T

- System pressure: 25Mpa

- Effective area of workbench: 1300mmx1300mm

- Slider stroke: 1700mm

- Nominal pressure: 12500KN

- Maximum clearance: 2500mm

Characteristics of 1250 Tons New Energy Battery Casing Forming Hydraulic Press:

- The body of the battery shell forming hydraulic press adopts a computer-optimized design and is an all-steel plate welded frame structure. And after high-temperature tempering treatment, the accuracy is good.

- The 1250-ton composite hydraulic press adopts a cartridge valve integrated system, which has reliable operation, large flow, small internal leakage, and long service life. The system is highly integrated, reducing connecting pipes and leak points.

- It adopts button centralized control and has two operation modes: adjustment and semi-automatic (directional single shot and constant pressure single shot).

- Four-corner and eight-sided guide rails. It has high guiding precision, a strong ability to carry eccentric loads, and adopts centralized lubrication.

- New cylinder sealing components, high reliability, and long life.

- The slider runs fast and has high work efficiency.

- The working pressure of the slider, the stroke range of no-load rapid descent, and the slow working advance can be adjusted according to process needs.

- The 1250-ton hydraulic press for stamping new energy battery shell adopts a servo control system, which is highly efficient and energy-saving. Pressure and speed are adjustable.

Advantages of New Energy Battery Shell Forming Hydraulic Press:

- Improve production efficiency: The high degree of automation and high-speed molding capabilities of the battery shell molding hydraulic press significantly improve production efficiency and shorten the production cycle.

- Ensure product quality: Due to their high-precision control and repeatability, these hydraulic presses ensure consistent quality of battery casings, reducing defective products.

- Energy saving and environmental protection: Hydraulic systems generally save more energy than traditional mechanical forming methods, reducing the environmental impact of the production process.

- Diversified applications: The new energy battery casing forming hydraulic press can be applied to various new energy battery technologies, including lithium-ion batteries, solid-state batteries, and fuel cells.

Applications of Battery Shell Molding Hydraulic Press:

- Electric vehicle manufacturing: The rise of electric vehicles has made new energy battery casing molding hydraulic presses essential production equipment to meet the growing market demand for electric vehicles.

- Energy storage systems: Energy storage systems are used to store electrical energy to balance energy supplies. The manufacturing of these systems requires high-quality battery housings, in which hydraulic presses play a key role.

- Electric bicycles and electric motorcycles: Electric two-wheeled vehicles also use new energy battery technology, so hydraulic shell-forming machines are used for their battery component manufacturing.

- Industrial energy storage: The industrial field also requires large-scale energy storage systems, so these hydraulic machines are also widely used in the field of industrial energy storage.

In summary, the hydraulic presses for stamping new energy battery shell forming play an indispensable role in the new energy industry. They improve production efficiency and product quality through performance features such as high-pressure molding, high-precision control, and automation functions, and provide critical manufacturing support for electric vehicles, energy storage systems, and other new energy applications. They are widely used in the field of new energy vehicle manufacturing.