Car longitudinal beams are also called car bottom beams. Together with the car’s cross beam, it forms a key part of the car’s load-bearing capacity. It is usually stamped from low alloy steel plate. Depending on the car model, there are many specifications and sizes of automobile longitudinal beams. If you want to press and shape large longitudinal beams at one time, you need to use a high-quality automotive longitudinal beam hydraulic press.

The hydraulic press for automobile longitudinal beams can complete the pressing, punching, stretching and other processes at one time only needs to be matched with a suitable mold. It has the advantages of high stamping precision and fast speed, and is suitable for mass production.

Automobile longitudinal beam hydraulic presses are also called automobile girder press forming presses. There are two types of fuselage structures commonly used. One is a multi-cylinder and multi-column structure automotive longitudinal beam hydraulic press. The other is a frame automotive longitudinal beam hydraulic press. Commonly used sizes include 2000 tons, 2600 tons, 3000 tons, 3500 tons, 4000 tons, 5000 tons, 6300 tons, etc. They are suitable for automobile longitudinal beam stretching process. In addition, it can also be used for other metal sheet press forming and correction processes.

Automobile Longitudinal Beam Forming Process Method

- Use blanking die to perform preliminary processing of sheet metal.

- Initial forming of the sheet metal surface.

- Shape and flange the sheet.

- Punching and trimming the sheet to complete stamping.

Technical Characteristics of Automobile Longitudinal Beam Hydraulic Presses

- The eccentric load is large during the forming process of the longitudinal beam. The machine adopts a slider intelligent balancing system and ensure the parallelism during the pressing process of automobile longitudinal and cross beam hydraulic press.

- The hydraulic press machine consists of multiple hydraulic pads. Hydraulic pad automatic synchronization technology is adopted to ensure that the movements of each hydraulic pad are synchronized during the forming and ejection of longitudinal beams.

- Adopt intelligent frequency conversion control technology to achieve stepless control of loading and unloading speed. And through Ethernet connection technology and PLC control technology, the position speed of loading and unloading and the production rhythm are reasonably matched, thereby improving production efficiency.

- The automobile longitudinal and crossbeam hydraulic press adopts a new six-column and twelve tie-rod structure. The press has good strength, small deformation during operation, strong ability to resist eccentric load, and low cost.

Multiple cylinders are evenly arranged, and which cylinders can be intelligently selected according to product conditions. At the same time, it automatically controls the opening and closing of the oil pump. In response to the forming requirements of longitudinal beams with variable cross-sections, the main cylinder of the press can be independently controlled whether to pressurize or not, ensuring the forming quality of automobile longitudinal beams and achieving energy saving and consumption reduction.

Product Features of Automotive Longitudinal Beam Hydraulic Press

- There are two types of machine tools: single machine and double machine linkage.

- The 4000-ton hydraulic press for automobile longitudinal beam is all welded components. After the whole fireplace is tempered and processed by a large CNC floor boring and milling machine, the accuracy is maintained well.

- The fuselage adopts a multi-pillar structure. The surface of the column has been treated by medium frequency quenching, which has good strength, high hardness, wear resistance and tensile resistance.

- The slider stroke uses imported displacement sensors to detect and send signals. Closed-loop control, electro-hydraulic proportional pump execution, good cylinder synchronization effect, and strong slider anti-eccentric load ability.

- This machine has independent power mechanism and electrical system. Adopt PLC control technology and advanced “human-machine interface” control. Centralized control by buttons enables adjustment and semi-automatic operation modes.

- The press is equipped with safety measures such as two-hand operation, multiple emergency stops, overload protection, eccentric load protection, and safety guardrails.

- According to user needs, the machine tool can be equipped with an upper feeding mechanism, lower hydraulic pad, mold changing lifting guide rail, mobile workbench, etc., and can provide users with machine tools with a frame structure.

Application of Hydraulic Press for Automobile Longitudinal Beams

The 4000T automotive longitudinal beam hydraulic press is mainly used for cold stamping of various large and medium-sized covering parts, stretching, bending, forming and other processes of thin plates. In order to expand the scope of the process, some products can also be punched and blanked (blanking) and other processes. It is generally suitable for the manufacturing process of thin plate parts forming in aviation, automobile, tractor, machine tool, instrument, chemical and other industries.

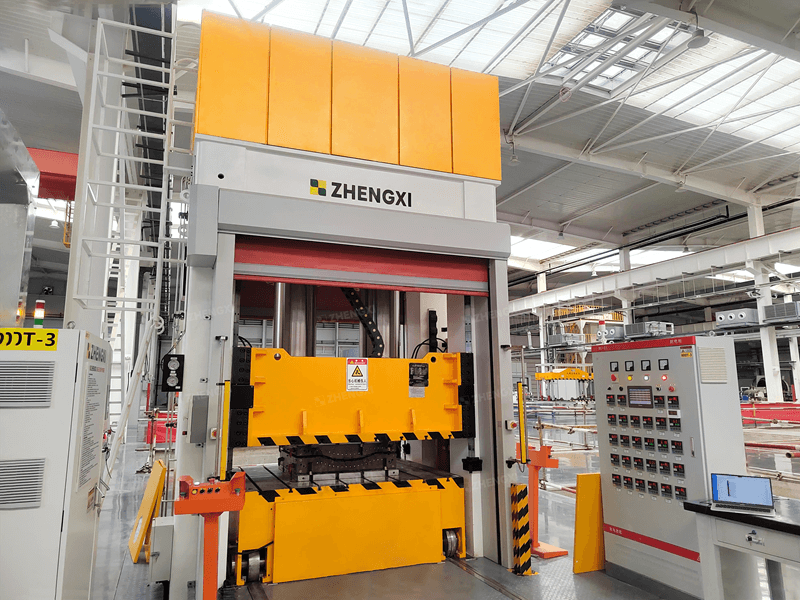

As a famous hydraulic press supplier in China, Zhengxi offers high-quality automobile longitudinal beam hydraulic presses and truck chassis hydraulic presses. If you have any needs, please contact us!