Automotive sheet metal parts are a type of automotive component, categorized as base components and auto parts, including crankshafts, cylinder blocks, cylinder heads, camshafts, frames, axle housings, and transmission cases. Automotive parts forming involves bending, arcing, stretching, and twisting flat sheet metal parts at specific angles. Automotive sheet metal forming equipment utilizes various hydraulic equipment, depending on the specific forming process.

Automotive parts deep drawing hydraulic presses are primarily used for stretching, flanging, and bending metal materials, and can also be used for pressing non-metallic materials. This equipment features high speed, flexible application range, high reliability, and economical usability. It ensures component quality, ease of use, and high productivity. It is suitable for bending, stretching, finishing, and straightening thick plates. Equipped with molds of varying specifications, it can produce automotive sheet metal parts of varying sizes and shapes.

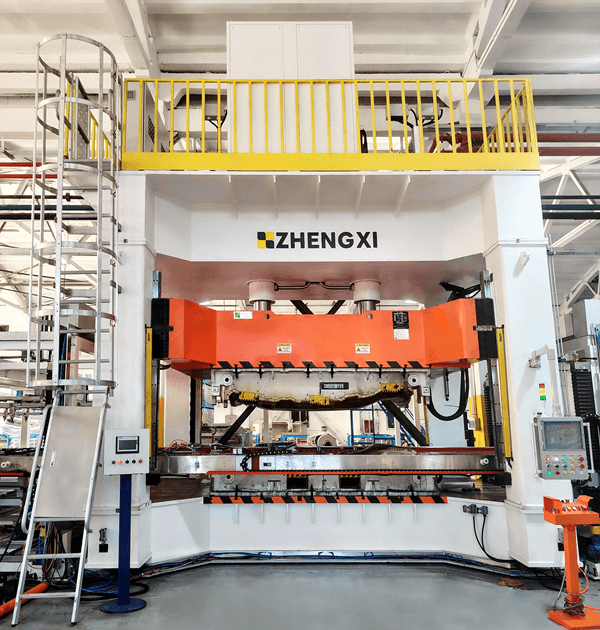

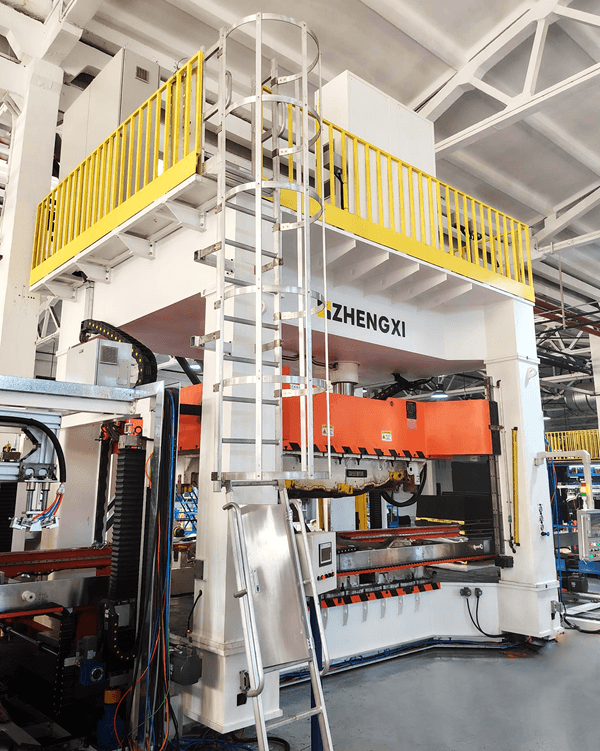

Our 400-ton frame-type hydraulic press is a custom-made machine designed specifically for automotive sheet metal stretching, tailored to meet the needs of our customers. It features a work surface measuring 1400 x 900 mm, an opening height of 1100 mm, and a cylinder stroke of 800 mm. It can be equipped with hydraulic pads and multiple ejectors. We also offer custom-made frame-type hydraulic presses in capacities ranging from 500 to 1600 tons. These presses are suitable for stretching automotive panels, molding, and hot forging automotive parts.

Features of the 400-ton automotive parts hydraulic press:

- The 400-ton hydraulic press utilizes a frame with eight guide rails on four sides, ensuring high precision and smooth operation.

- The frame and movable table offer high precision, excellent rigidity, and strong resistance to lateral forces, making it particularly suitable for pressing high-precision, asymmetrical products.

- It utilizes Mitsubishi or Siemens programmable controllers.

- It is primarily suitable for cold extrusion, coining, shallow drawing, and blanking of metal materials.

- The movable table of the 400-ton automotive parts hydraulic press offers high speed and high production efficiency.

- The cylinder is integrally forged and ground, ensuring high reliability under high pressure.

- The hydraulic control utilizes an integrated cartridge valve system, resulting in minimal leaks, minimal impact, and reliable operation, effectively protecting the life of the mold and equipment.

- The 400-ton frame hydraulic press is equipped with an automatic guide rail lubrication device to fully protect the guide posts and maintain precision.

- Mechatronic safety features, such as a support circuit for the lower cylinder chamber and an interlocking circuit for the upper and lower cylinder chambers, provide excellent safety.

Applications of the 400-ton Auto Parts Hydraulic Stretching Press

The 400-ton hydraulic stretching press can also stretch other products, such as stainless steel dish sinks, ash truck hopper basins, crash helmets, hardware, auto parts, stainless steel kitchen utensils, stainless steel water tank plates, headers, stainless steel sinks, rice cooker liners, automotive longitudinal and transverse beams, bridge corrugated steel webs, and automotive panels. Simply by changing the mold, a variety of stretched products can be produced.

Chengdu Zhengxi offers high-quality deep drawing hydraulic presses for the production of automotive parts. If you need any, please contact us.