A hydraulic press is a machine that uses hydrostatic pressure to process metal, plastic, rubber, wood, powder, and other products.

Table of Contents

- What is the Hydraulic Press

- How does Hydraulic Press Work

- Types of Hydraulic Press

- Advantages of Hydraulic Press

- Disadvantages of Hydraulic Press

- What is a Hydraulic Press Used for

What is the Hydraulic Press

A hydraulic press refers to a machine that uses high-pressure liquid (oil, emulsion) as the working medium and transmits working pressure to realize various processes according to Pascal’s principle. It is often used in the pressing process and press forming process, such as: forging, stamping, cold extrusion, straightening, bending, flanging, sheet drawing, powder metallurgy, pressing, and so on.

The hydraulic press is generally composed of three parts: the main engine, the power system, and the hydraulic control system. It has the advantages of variable stroke, high working pressure, and stable work. The hydraulic press machine can reach a large forging depth, so it is suitable for the production of large forgings. During the production process, blank opening, upsetting, cutting, elongation, and other processes can be carried out on the hydraulic press.

How does Hydraulic Press Work

The basic principle of the hydraulic press is that the oil pump delivers the hydraulic oil to the integrated cartridge valve block. The hydraulic oil is distributed to the upper chamber or the lower chamber of the cylinder through various check valves and overflow valves. Under the action of high-pressure oil, the oil cylinder is moved. A hydraulic press machine is a device that uses liquid to transmit pressure. When a liquid transmits pressure in a closed container, it obeys Pascal’s law.

Working medium of hydraulic press

The function of the working medium used in the hydraulic machine is not only to transmit pressure but also to ensure that the working parts of the machine work sensitively, and reliably, with long life and less leakage.

The basic requirements of the hydraulic press for the working medium are:

- It has suitable fluidity and low compressibility to improve the efficiency of transmission.

- Anti-corrosion.

- Good lubrication performance.

- Easy to seal.

- Stable performance, long-term work without deterioration.

Hydraulic presses initially used water as the working medium. Later, it was changed to an emulsion made by adding a small amount of emulsified oil to water. This increases lubricity and reduces rust. In the later period, hydraulic presses with mineral oil as the working medium appeared. The oil has good lubricity, corrosion resistance, and moderate viscosity, which is beneficial to improve the performance of the hydraulic press.

Types of Hydraulic Press

There are many types of hydraulic presses. According to different classification methods, there are different types.

- According to the type of liquid that transmits pressure, there are two types of oil hydraulic presses and water hydraulic presses.

- According to the structural form, it is mainly divided into four-column type, single-column type (C type), horizontal type, vertical frame, universal hydraulic press, etc.

- According to the application, it is mainly divided into metal forming, bending, stretching, punching, powder (metal, non-metal) forming, pressing, extrusion, etc.

- According to the products to be pressed, there are also hydraulic presses of different tonnages. At present, the tonnages of our hydraulic presses are 63T, 100T, 150T, 200T, 250T, 300T, 315T, 500T, 630T, 800T, 1600T, 2000T, 2500T, 3150T, 4000T, 5000T, etc.

Advantages of Hydraulic Press

1. Easy access to maximum pressure

Since the hydraulic press adopts hydraulic transmission and static pressure work, the power equipment can be arranged separately. And multiple cylinders can work together. So it is possible to manufacture hydraulic presses machine with a large tonnage, such as 700,000 kN die-forging hydraulic presses. However, large forging hammers have vibrations, which require a large anvil and foundation to prevent shocks, and the crank press is limited by the strength of the crank connecting rod, so it is not suitable to make it too large.

2. Easy access to large work trips

The hydraulic press is easy to obtain a large working stroke and can exert full pressure at any position of the stroke. Its nominal pressure has nothing to do with the stroke, and it can stop and return at any position in the stroke. In this way, it is very convenient for the process that requires a long working stroke (such as deep drawing), as well as the installation of molds, pre-pressing, batch charging, or troubleshooting.

3. Easy access to a large workspace

Because it does not have a huge mechanical transmission mechanism, and the working cylinders can be arranged arbitrarily, the working space is large, which is convenient for organizing automated production lines.

4. Pressure and speed can be adjusted steplessly

Pressure and speed can be easily adjusted steplessly within a wide range.

5. Easy to control stress

Generally, the three-cylinder hydraulic machine can easily obtain three different pressures. If the high-pressure liquid is passed into the middle working cylinder, the primary pressure will be obtained. If it is passed into the working cylinders on both sides, the secondary pressure will be obtained. If the high-pressure liquid is passed into the three working cylinders at the same time, the full pressure will be obtained. And according to the process requirements, it can hold pressure for a long time in a certain stroke. Get reliable protection against overload due to reliable control of hydraulic pressure.

6. Easy to adjust the speed

The speed of the slider can be adjusted to a considerable extent within a certain range so that it can adapt to the different requirements of the process for the speed of the slider. When the pump is directly driven, the adjustment of the slider speed can be independent of the pressure and stroke.

7. Standardization of hydraulic components

Hydraulic components have been applied, standardized, and serialized. These bring convenience to the design and manufacture of the hydraulic press. And the hydraulic operation is convenient, which is convenient for remote control and automation.

Disadvantages of Hydraulic Press

- Due to the use of high-pressure liquid as the working medium (mechanical oil or emulsion), the precision requirements for hydraulic components are relatively high. The structure is relatively complicated, and the adjustment and maintenance of the machine are relatively difficult.

- At present, the leakage problem of liquid is still unavoidable. This not only pollutes the working environment, wastes pressure oil, but also has the danger of fire when used in thermal processing plants.

- There is a pressure loss in the flow of liquid and therefore less efficient. The efficiency is especially low when moving at high speed, so the fast small hydraulic press is not as simple and flexible as the crank press.

- Due to the compressibility of the liquid, it may cause the vibration of the press body or the hydraulic system when unloading quickly, so it is not suitable for punching, shearing, and other processes.

- The working fluid has a certain service life and should be replaced after a certain period of time.

- When the pump is directly driven, the installed power is larger than that of the corresponding mechanical press.

- Since it takes a certain amount of time to increase and decrease the pressure in the working cylinder, it also takes a certain amount of time to change the direction of the valve. And the idle speed is not high enough, so it is not as fast as a mechanical press.

What is a Hydraulic Press Used for

At present, hydraulic presses are mainly used in the following fields:

(1) The stamping and stretching forming process of metal sheet parts are mainly used in the forming and processing of metal covering parts in the automobile and home appliance industries.

(2) Pressure forming of metal mechanical parts, mainly including compression molding, extrusion forming of metal profiles, hot and cold die forging, free forging, and other processing techniques.

(3) Powder products industry, such as magnetic materials, powder metallurgy, etc.

(4) Compression forming of non-metallic materials, such as SMC forming, thermoforming of automotive interior parts, rubber products, etc.

(5) Hot pressing of wood products, such as hot pressing of plant fiber boards and profiles.

(6) Other applications: such as pressing, calibration, plastic sealing, embossing, and other processes.

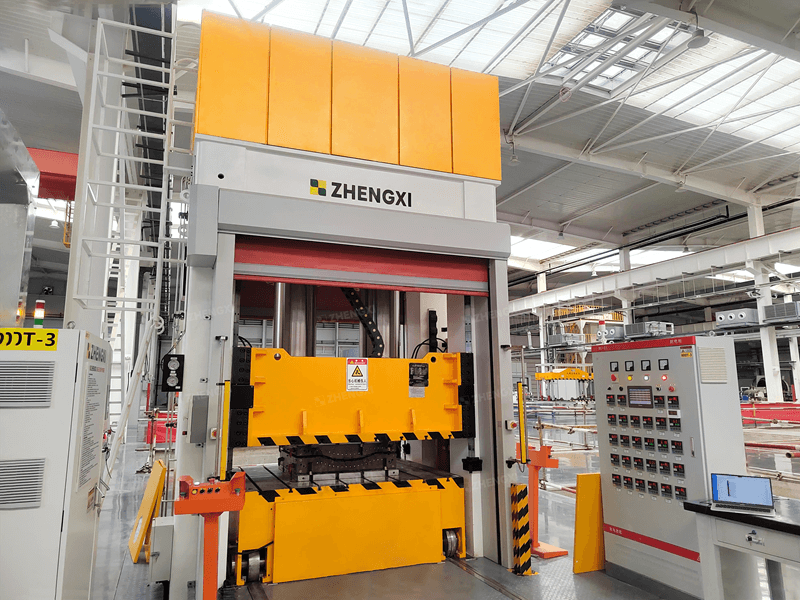

Zhengxi has a group of professional hydraulic press technicians to answer all related questions for you. Contact us now.