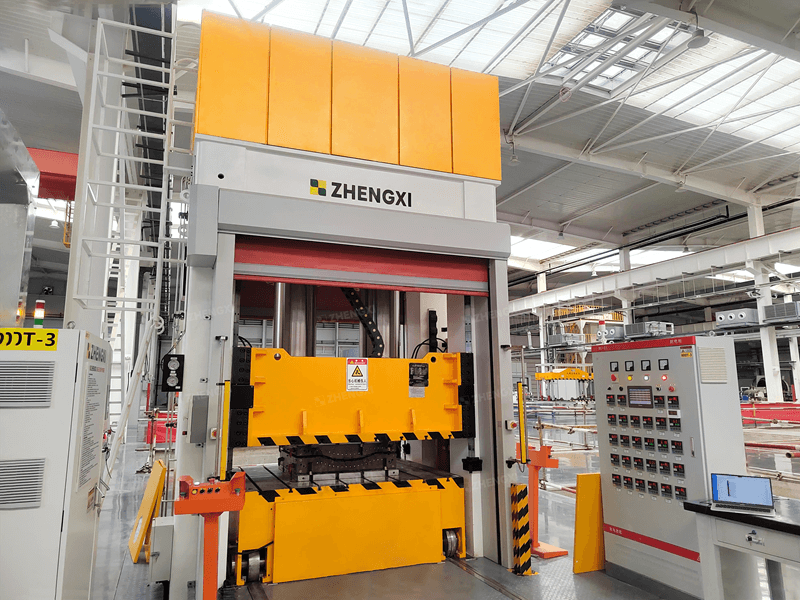

A train door panel stamping machine is a kind of mechanical equipment used to manufacture train doors. Its function is to manufacture train door panels by placing sheet metal in the equipment and then applying pressure and impact to shape the sheet into the desired shape and size. This equipment is often used in mass manufacturing to ensure consistent quality and accurate dimensions for vehicle doors.

Our 3000-ton deep drawing hydraulic press is very suitable for metal material forming, sheet metal bending, drawing, cold punching, extrusion processing, etc. It adopts a four-column structure, which is economical and practical. The equipment has sensitive and reliable movements, fast speed, low energy consumption, and low noise. The pressure and stroke can be adjusted arbitrarily within the specified range, and the operation is simple.

The main part of the truck train door panel forming hydraulic press includes hydraulic cylinders, beams, columns, and liquid filling devices. The power mechanism consists of a fuel tank, a high-pressure pump, a control system, an electric motor, a pressure valve, a directional valve, etc. The hydraulic control adopts a cartridge valve integrated system to reduce leakage points, ensure reliable operation, and have a long service life.

It can realize both constant pressure and fixed stroke molding processes and has the function of maintaining pressure holding time. The working pressure and stroke can be adjusted within the specified range. The train door panel forming machine adopts button centralized control and has three operating modes: adjustment, manual, and semi-automatic.

The Process Flow of a 3000-ton Hydraulic Press for Stamping Train Door Panels:

- Place the cut plate of a certain size in the mold cavity of the hydraulic press.

- Start the train door panel forming hydraulic press, and the oil cylinder pushes the slider to drive the upper mold downward.

- The upper mold and the lower mold are closed, and the molding is formed after a certain period of pressure holding.

- The oil cylinder returns and the upper mold and lower mold are separated.

- The ejection cylinder ejects the door panel in the mold cavity.

- Take it out and you will get a train door panel product of a certain shape and size.

Characteristics of the 3,000-ton Train Door Panel Forming Hydraulic Press:

- The train door panel stamping machine adopts a four-column structure. The frame and movable workbench have high guiding precision, good rigidity, and strong resistance to lateral force. Especially suitable for pressing asymmetrical products. Compact structure, high-cost performance, economical and applicable.

- The hydraulic control adopts a cartridge valve integrated system, which has a small impact, reliable action, and few leakage points.

- The oil cylinder is integrally forged and precision ground. The new cylinder sealing element has strong reliability and long service life under high-pressure conditions.

- The stretching and blanking sliders can be connected into one body to realize single-action process actions. The guide rail has an automatic lubrication device, which is beneficial for improving work efficiency and operating safety.

- The four columns are made of high-strength alloy steel, with hard chromium plating on the surface and good wear resistance.

- The working pressure and stroke of the 3000-ton train door panel forming hydraulic press can be adjusted within the specified range according to process requirements. It adopts button centralized control to realize three operation modes: manual, semi-automatic, and automatic.

- The electrical system is controlled by PLC.

- Two molding processes of constant pressure and fixed stroke can be realized. It has a pressure-maintaining delay function and the delay time is adjustable.

Advantages of 3000-ton Train Door Panel Stamping Machine:

- High pressure: The maximum pressure of this hydraulic press reaches 3,000 tons, which can meet the high-pressure requirements for molding and ensure molding quality.

- Large workbench area: The 3000-ton press has a larger workbench area, which can adapt to the molding needs of large-sized workpieces and improve production efficiency.

- Reliable working accuracy: The train door panel forming hydraulic press adopts precise pressure sensors and hydraulic system control. It can ensure the working accuracy during the molding process and improve the product quality.

- Easy to operate: It adopts an advanced digital hydraulic control system, which has the characteristics of easy operation and high reliability. Operators only need simple training to operate.

- High efficiency: The train door panel stamping forming machine is driven by a hydraulic system, which is fast and efficient, improving production efficiency.

- The high degree of automation: The hydraulic press adopts an automated control system, which can realize automated operations of various molding tasks and reduce labor intensity.

- Professional application fields: The 3,000-ton four-column hydraulic press can be widely used in the molding of large structural parts in vehicles, rail transit, aviation, ships, and other industries to meet the needs of molding production.

Zhengxi provides high-quality train door panels forming hydraulic presses, which are used to press side door panels of railway trains and door panels of freight trains. Machinery and equipment for stamping train door panels generally require relatively large tonnage. Commonly used are 3000 tons, 4000 tons, 5000 tons, and other four-column hydraulic presses or frame hydraulic presses. If you have any needs, please contact us.