A hydraulic press is a machine that uses hydraulic oil as the power source and circulates the hydraulic oil in the oil tank through the force of the hydraulic pump. Let the cylinder/piston do work in a cycle to complete a certain mechanical action, as a kind of productivity machine. According to the structural form, hydraulic presses are divided into: four-column hydraulic presses, C-type hydraulic presses, horizontal hydraulic presses, frame hydraulic presses, universal hydraulic presses, etc. According to the application, it is mainly divided into metal forming, bending, stretching, punching, powder (metal, non-metal) forming, pressing, extrusion, etc.

Different products use hydraulic presses with different structural tonnages. The same hydraulic press can also change the mold to complete the processing of different styles of products. The hydraulic press machine is a multifunctional forging machine tool. It is widely used in aerospace, nuclear power, petrochemical, auto parts, bicycle parts, hardware products, instruments, medical equipment, household appliances, household utensils, sanitary kitchen utensils and other manufacturing industries.

This article will introduce in detail the uses of hydraulic presses in various industries.

Table of Content:

- Automobile Industry

- Appliance Industry

- Agriculture

- Rubber Industry

- Metal Parts Industry

- Ceramic Industry

- High Tech Industry

Automobile Industry

1) Body panels and brake pads

At this stage, steel plates are the most widely used material for car bodies, and different steel plates are used for different parts of the car body. For body surface parts, steel materials with good extensibility, corrosion resistance and dent resistance are used, and for structural parts, materials with good energy absorption, certain rigidity, and good corrosion resistance are used.

Most of the body panels are composed of inner and outer panels, and the outer panel is usually the A side, which requires high surface quality. At present, due to the relative maturity of stamping technology, the improvement of stamping equipment, and the improvement of mold production equipment, stamping is still the most common forming process for body panels. Generally, the stamping and stretching operation of the body panel is performed using a deep drawing hydraulic press to complete the manufacture of the car shell.

2) Automotive Interior

Automotive interior decoration products include headlining, carpets, heat insulation materials, door panels, door inserts, door pillars, sun visors, roof panels, rear window panels, trunk side panels, door storage boxes, Driver’s seat rear walls, dashboard panels, steering wheel, seat cover, pre-canopy, inner door panel, trunk lining, engine hood lining, the interior roof, rear wall, etc. The production of car interiors can use specialized hydraulic presses for automotive interiors, which are suitable for press molding, edge cutting, and cutting of interior products.

The process of hydraulic press molding automotive interior parts is divided into feeding, mold clamping, forming, demolding, and mold cleaning. The compression molding process is to heat the sheet to reach a temperature above the softening temperature (for example, the PU board for the ceiling should be heated to 220-240 degrees Celsius). It is then quickly moved over the forming die to secure the sheet to the edge of the die. The sheet is formed by mold pressure (forming time is about the 90s). There is an internal circulating cooling water device in the forming mold, which is closely attached to the outer contour of the mold. After cooling and shaping, the product is water-cut and trimmed to obtain a thin shell-shaped open product.

3) Auto parts

the processing technology of auto parts includes casting, forging, stamping, welding, powder metallurgy, plastic molding, etc.

Forgings are the result of plastic deformation of materials, so the grains of forgings are finer, without the coarse structure and internal defects of castings. Some important parts that require high strength, impact resistance, and fatigue resistance mostly use forging hydraulic presses to forge blanks, such as various Gears, various shafts, camshafts, connecting rods, upper and lower suspension arms, steering knuckles, steering knuckle arms, etc.

Appliance Industry

Plastic is a synthetic or natural polymer. Compared with metal, stone, and wood, plastic products have the advantages of low cost and strong plasticity. The plastics industry occupies an extremely important position in the world today. It is widely used in home appliances, especially small home appliances. Composite hydraulic presses are ideal for forming sheet materials and are a great way to press housings for various household appliances.

Agriculture

Farming probably wasn’t the first industry that needed a hydraulic press since farmers worked with plants. However, they need a lot of big farm equipment to run their business. They use hydraulic presses to perform repair tasks such as the separation of rusted parts, the straightening of bent parts, and the compression of unwanted materials. They also use it to press out bearings for equipment.

Rubber Industry

Rubber products are widely used and there are many varieties. According to the use, it is usually divided into two categories: industrial use and civil use. Industrial rubber products mainly include tires, tapes, hoses, offset plates, tapes and tape products, seals, shock absorbers, latex products, hard rubber products, rubber insulation products, rubber rollers, and rubber linings.

In the production process of rubber products, the molding method is used to manufacture some rubber products with complex shapes (such as leather cups and sealing rings). With the help of formed female and male molds, the rubber is placed in the mold and heated for molding. The whole process uses a composite material hydraulic press.

Metal Parts Industry

The commonly used metal material forming process is the process method of producing parts, which is cold and hot forming.

Forging is a processing method that uses hydraulic forging machinery to apply pressure to metal blanks to cause plastic deformation to obtain forgings with certain mechanical properties, certain shapes, and sizes. Forging can eliminate defects such as as-cast porosity produced in the metal smelting process and optimize the microstructure. At the same time, due to the preservation of complete metal flow lines, the mechanical properties of forgings are generally better than castings of the same material.

Powder metallurgy is a process technology that uses metal powder (or a mixture of metal powder and non-metal powder) as raw material, after forming and sintering, to manufacture metal materials. Powder compaction uses a hydraulic powder compacting press to compact parts with complex shapes, such as various oil-impregnated bearings, mechanical structural parts, etc. The degree of mechanization and automation is higher.

Ceramic Industry

Common molding methods for ceramics include dry pressing, casting, and injection. Among them, dry pressing molding is the most widely used molding process, and it is also one of the mainstream molding processes for mobile phone ceramic backplanes.

Dry pressing, also known as compression molding, is one of the most commonly used molding methods. The powder-forming hydraulic press uses the dry-pressing forming process. Put the granulated powder with good fluidity and suitable particle size into the metal mold cavity. The pressure is applied by the indenter, the indenter is displaced in the mold cavity, and the pressure is transmitted, so that the powder particles in the mold cavity are rearranged and deformed to be compacted, forming a ceramic green body with a certain strength and shape.

High Tech Industry

Some high-tech industries apply new materials, such as graphene. Compress hundreds of thousands of graphene films into a composite material, which is used in aviation, mobile phones, computers, and high-tech fields. These industries are inseparable from the use of composite hydraulic presses.

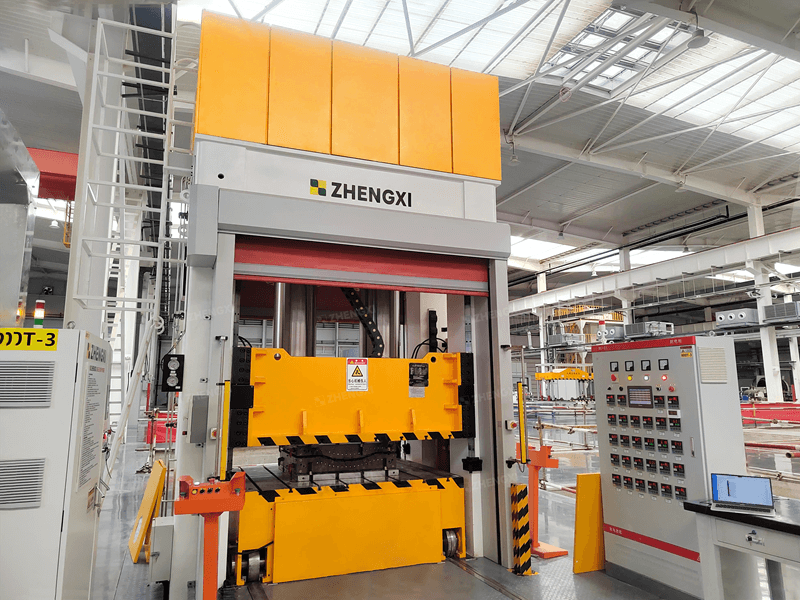

In short, hydraulic presses are widely used in our lives. From household appliances used in daily life to parts in the industry, hydraulic press machines are required to complete the forming process. Zhengxi Hydraulic Equipment Co., Ltd. is a professional hydraulic press manufacturer, with various types of hydraulic equipment, including composite hydraulic presses, forging hydraulic presses, deep drawing hydraulic presses, powder compacting hydraulic presses, etc. If you have any needs, please contact us. Our sales will provide you with the perfect hydraulic press solution.