The stainless steel plate pressing hydraulic press is a device specially used to press stainless steel plates into the desired shape. It uses a hydraulic system as its power source and applies pressure through a hydraulic cylinder to shape and size the stainless steel plate as required.

This deep drawing press machine features a three-beam, four-column structure, made of overall 45# cast steel, tempered and aged. The hydraulic control adopts a cartridge valve integrated system to reduce leakage points and ensure more reliable action. It occupies a small area, is simpler than the original slide valve structure, and is easier to maintain. The service life is greatly extended.

Features of Stainless Steel Partition Plate Press Machine

- High pressing force: The hydraulic system provides sufficient pressure. Assemble the mold and place it on a stainless steel plate, which can effectively press the plate into the shape of a dinner plate.

- Large workbench size: To accommodate stainless steel dinner plates of varying sizes, hydraulic presses typically feature larger workbenches, providing sufficient space for pressing operations.

- Accurate pressing control: The hydraulic press is equipped with an advanced control system, which enables accurate pressing control to ensure the consistency of size and shape of the stainless steel dinner plates.

- Automated operation: The hydraulic press can be equipped with automation devices, such as PLC control systems and touch-screen interfaces, to achieve automated operation and control, improving work efficiency and accuracy.

- Safety protection devices: Hydraulic presses are typically equipped with various safety protection devices, including overload protection, emergency stop buttons, and protective covers, to ensure the safety of both operators and equipment.

- High quality and reliability: The key components of the hydraulic press are made of high-quality materials and undergo advanced processes, ensuring high quality and reliability. It can operate stably for a long time.

Stainless Steel Dinner Plate Hydraulic Press Application Areas:

This series of hydraulic presses is a general-purpose hydraulic press, also known as a universal hydraulic press. Suitable for metal material stretching, bending, flanging, cold extrusion, punching, and other processes, and also suitable for correction, press fitting, powder products, abrasive products pressing and forming, and plastic products, insulating materials pressing and forming.

Optional Accessories of the Hydraulic Press for Pressing the Stainless Steel Plate:

- Blanking buffer device;

- Mobile workbench light curtain safety protection device;

- Cooling device, floating guide rails, and rolling brackets for mold change.

A stainless steel partition plate forming press is a type of equipment used specifically to press stainless steel plates into the desired shape. It has the characteristics and functions of high pressing force, large workbench size, precise pressing control, automatic operation, safety protection device, high quality, and reliability. It plays a crucial role in the stainless steel plate manufacturing industry, improving production efficiency and product quality.

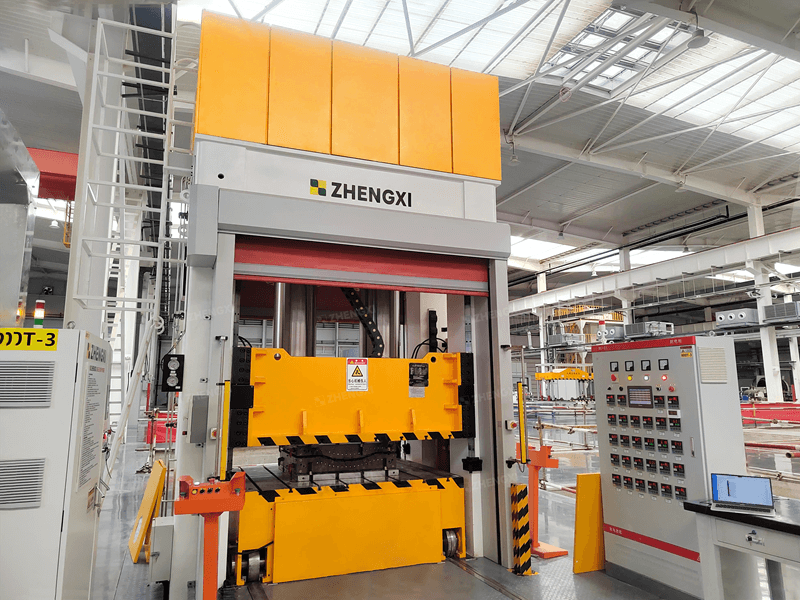

As a professional hydraulic press factory, Zhengxi provides high-quality stainless steel plate hydraulic presses to help you increase production and increase benefits. If you have any needs, contact us immediately.