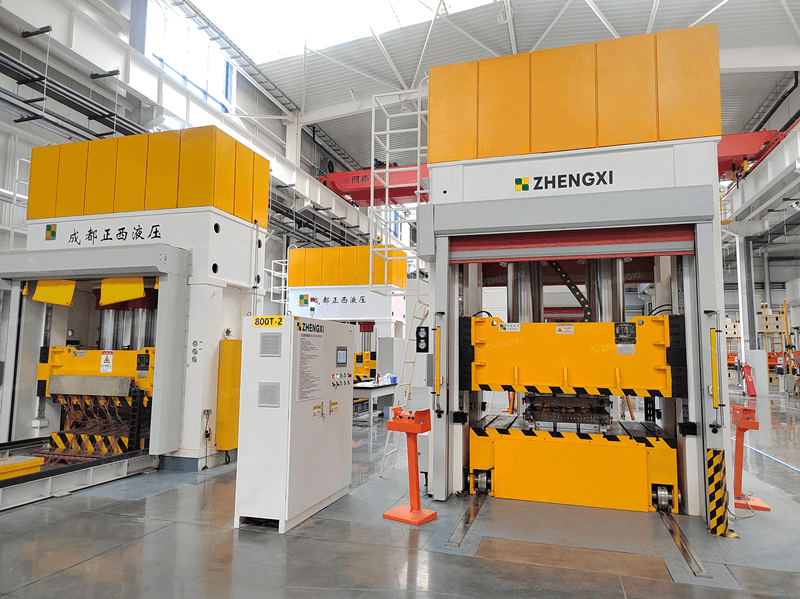

Resin transfer molding (RTM) refers to a composite material molding process in which resin is injected into a preform and solidified together to form an overall structure. This process is increasingly used in low-cost molding technology for advanced composite materials. RTM presses are specially designed for the RTM process.

Our RTM forming press has the advantages of low cost, short cycle time, large batches, and high-quality production (good part surface). It is used in many industries such as automobile manufacturing, shipbuilding, aircraft manufacturing, agricultural machinery, railway transportation, wind power generation, and sporting goods.

Requirements for presses in the RTM process:

- Tonnage to ensure clamping force.

- Ensure the overall rigidity of the fuselage.

- Automated integrated control of injection machines, mold temperature controllers, etc.

Zhengxi Hydraulic Equipment Co., Ltd. provides high-quality RTM presses that can adapt to RTM, HP-RTM, and C-RTM processes.

Resin Transfer Molding Press Production Process

Features of RTM Press

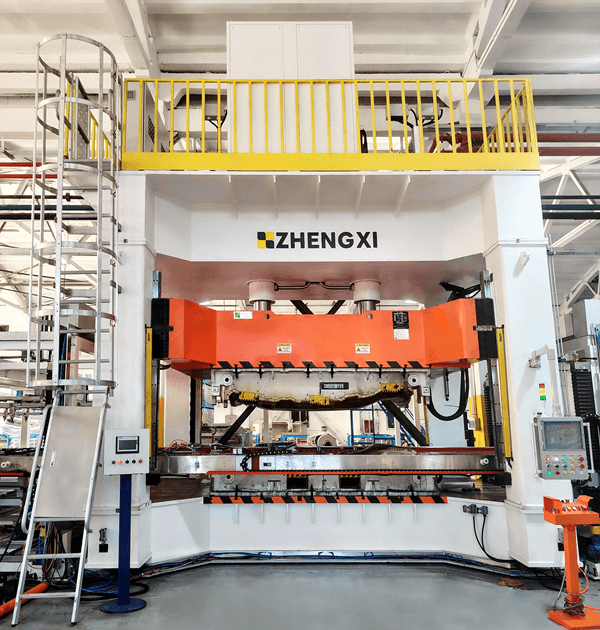

- Fast movement speed, short pressure building time, and active slider balance control. High-quality parts with very thin walls can be produced.

- The speed profile in the stamping process is controllable. Greater flexibility in component production.

- Press configuration features optimized deflection for uniform wall thickness

- The roller guide of the slide has a closing function to ensure free movement of the slide during the stamping process.

- Independent cylinder. Used for double slider balance control and smooth opening of the mold to avoid damage to parts.

- The accumulator drive enables efficient energy utilization and shortens pressure build-up time.

Advantages of Resin Transfer Molding Machine

- The fuselage is welded with Q355B high-quality carbon steel material, which has higher strength.

- When welding the fuselage, the welding thickness should not be less than 75% of the plate thickness, and high-temperature annealing after welding should eliminate stress.

- The guide contact surface of the slider is made of copper-based composite material, which has good wear resistance.

- It adopts imported PLC and touchscreen control and is equipped with a Zhengxi cloud platform data management system.

- Large-diameter pipelines are connected using SAE flanges to reduce the amount of welding as much as possible.

- Major electrical appliances use Schneider and other high-quality components to improve overall quality.

Technical Parameters of RTM Presses

| Main parameters | YP78-2000 | YP78-2500 | YP78-3000 | YP78-3500 | YP78-4000 | YP78-5000 |

| Nominal force / KN | 20000 | 25000 | 30000 | 35000 | 40000 | 50000 |

| Liquid max pressure / Mpa | 25 | 25 | 25 | 25 | 25 | 25 |

| Opening / mm | 2600 | 3000 | 3200 | 3400 | 3600 | 4000 |

| Stroke / mm | 2200 | 2600 | 2800 | 2800 | 3000 | 3200 |

| Workbench (left and right) / mm | 3000 | 3500 | 3600 | 4000 | 4000 | 4200 |

| Workbench (front and rear) / mm | 2000 | 2500 | 2500 | 3500 | 3500 | 3500 |

| Overall height of equipment / mm | 8200 | 11000 | 11800 | 1200 | 12500 | 14000 |

| Fast down speed / mm/s | 800 | 800 | 800 | 600 | 600 | 600 |

| Pressing speed / mm/s | 1-80 | 1-80 | 1-80 | 1-80 | 1-80 | 1-80 |

| Fast return speed / mm/s | 700 | 700 | 600 | 500 | 500 | 500 |

| Power / KW | 168 | 270 | 300 | 350 | 380 | 500 |

Product Details of Resin Transfer Moulding (RTM) Press

1. Hydraulic cylinder

Standardized design, full plunger cylinder structure, reliable operation.

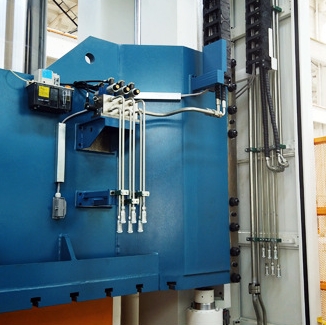

2. Hydraulic system

Fully imported servo system control, integrated hydraulic system, no welding pipe connection, no leakage.

3. Electrical control

Siemens PLC and touch screen control system runs fast and operates quickly.

4. Spare oil line

Standardized oil circuit design, quick connector one-click pressure relief, enabling quick mold change.

Terminal Products