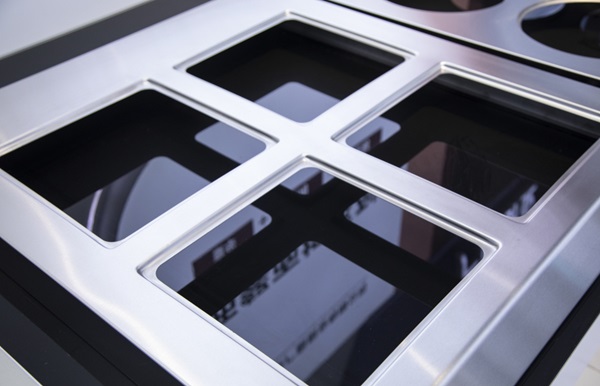

This hydraulic press is a highly efficient equipment designed to produce gas stove bodies. It is widely praised in the industry for its excellent performance and stable quality. It not only uses the most advanced hydraulic technology but also combines a sophisticated control system to ensure that the manufacturing of each gas stove body meets the highest standards. Whether it is production efficiency or product quality, our hydraulic press for gas stove body can meet and exceed your expectations.

Our 500-ton gas stove body hydraulic press adopts a three-beam and four-column structure. The body consists of an upper beam, a sliding beam, a workbench, a hydraulic pad, a push rod, a cylinder, a column, a liquid filling tank, a limit mechanism, etc. A servo system controls the hydraulic press for the gas stove body, and the stretching pressure, speed, and displacement accuracy are well-controlled to ensure that the stretched product is highly consistent. The hydraulic press has a PLC programmable controller and a touch screen, which can intuitively view some data and make adjustments on time. The operating buttons of the deep drawing hydraulic press are integrated into a movable button operating table, and its position can be moved at will within a certain distance range for easy operation.

The 500-ton hydraulic press to make a gas stove body is equipped with a hydraulic pad device, which is particularly suitable for various deep and shallow stretching processes. It can effectively prevent wrinkles or cracks caused by too fast material flow during sheet forming, and improve the tensile quality of the workpiece. It is especially good for aluminum sheet stretching and aluminum product pressing in stainless steel product factories, as well as the positive and negative stretching of stainless steel products.

Features of the Hydraulic Press for Gas Stove Body:

- The body is a four-column structure, and the load-bearing parts are optimized and designed, with a beautiful appearance and economical applicability.

- The volume of the hydraulic press filling tank is increased to ensure fast filling and reduce the pressing time. Increase the heat dissipation area and reduce the oil temperature.

- The end modulus of the three beams of the main engine is large, which improves the rigidity of the three beams and greatly prolongs the service life.

- The main cylinder and piston rod of the hydraulic press are made of high-quality forgings, which improves reliability.

- The main rod adopts a four-nut structure, which improves the pre-tightening performance and can maintain the stability of accuracy for a long time.

- The surface of the piston rod and the column is quenched and hard chrome-plated to improve wear resistance and prevent surface corrosion and scratches.

- The advanced cartridge valve is adopted, with a compact structure, reduced pipeline connections, improved system sealing, and reduced leakage.

- The power system adopts an oil-immersed vertical pump group to reduce noise, good oil absorption effect, and increase the life of the pump.

- The pressure gauge adopts a seismic pressure gauge and is equipped with a pressure gauge valve for easy maintenance.

- The electrical control system has two control schemes: relay and PLC. The electrical system controlled by PLC is sensitive, reliable and flexible. The operation buttons are concentrated on the panel and equipped with a movable button station for easy operation. It has two operation modes: adjustment and two-hand single cycle.

Technical Parameters of Hydraulic Press for Gas Stove Body

| Item | Unit | Product Specifications | |||||

| YzS-150T | YzS-200T | YzS-250T | YzS-350T | YzS-500T | |||

| Nominal Force | kN | 1500 | 2000 | 2500 | 3500 | 5000 | |

| Max.Working Pressure | Mpa | 20 | 21 | 22 | 22 | 20 | |

| Master Cylinder Nominal Force | kN | 1000 | 1500 | 1750 | 2500 | 3000 | |

| Max.Stroke of Ram | mm | 550 | 550 | 600 | 650 | 750 | |

| Daylight (Max.Open Height) | mm | 850 | 900 | 1000 | 1100 | 1300 | |

| Lower Cylinder Nominal Force | kN | 500 | 500 | 750 | 1000 | 2000 | |

| Stroke of Lower Cylinder | mm | 250 | 250 | 250 | 300 | 350 | |

| Upper Ejection Cylinder Force | kN | 30 | 30 | 30 | 50 | 50 | |

| Stroke of Upper Ejection Cylinder | mm | 230 | 230 | 230 | 280 | 320 | |

| Speed of Ram | Down No Load | mm/s | 350 | 380 | 320 | 380 | 290 |

| Pressing | mm/s | 2~40 | 2~40 | 2~40 | 2~40 | 2~40 | |

| Return | mm/s | 340 | 360 | 320 | 300 | 290 | |

| Effective Area of Working Table | RL(Inside Column) | mm | 620 | 700 | 800 | 950 | 1200 |

| FB(Edge) | mm | 750 | 850 | 900 | 1100 | 1400 | |

| Overall Dimension | L.R | mm | 1940 | 2140 | 1650 | 2430 | 2780 |

| F.B | mm | 1380 | 1820 | 1890 | 2000 | 2400 | |

| H | mm | 3250 | 3440 | 3890 | 4250 | 4750 | |

| The Distance Between the Working Table and the Ground | mm | 1120 | 1120 | 1300 | 1340 | 1700 | |

| Servo Motor Power | kW | 16.4 | 24.5 | 24.5 | 31 | 49.6 | |

| Total Weight(Approx) | Ton | 5.1 | 6.3 | 9.2 | 11 | 20.9 | |

| Oil Quantity(Approx) | L | 500 | 650 | 700 | 800 | 900 | |

Application of Hydraulic Press for Gas Stove Body

Zhengxi‘s 500-ton hydraulic press for the gas stove body can be used in production processes such as deep drawing, stamping, cutting, bending, and metal plate folding. In addition to aluminum sheet stretching and stainless steel tableware forming production, it is also suitable for the following industries:

Containers: stainless steel aluminum, copper hot pot, enamel bath, pressure vessel, stainless steel sink, utensils, rice, pot stainless steel liner, aluminum liner, bathtub, etc.

Automobile industry spare parts: diesel engine spare parts, tractor parts, motorcycle spare parts, aerospace, shipbuilding, automobile covering parts (battery cover, body, chassis, bushing, fuel tank, door, trolley tray), etc.

Daily utensils: sheet stretching, stainless steel cup, aluminum pot cover, stainless steel kettle, copper spoon, barbecue outdoor products, plate, etc.

Kitchenware industry: stainless steel utensils, liquefied petroleum gas cylinders, cooking tables, aluminum cookware.

Metal products: metal product shell, air conditioner shell, water heater shell, heater stretching, boiler head, etc.

Furniture: stretching of hardware furniture, stretching of daily industrial products, stretching of lamp housings, gas stove housings, household appliance parts, air conditioners, refrigerators, washing machines, microwave ovens, rice cookers, etc.