The steel door panel embossing press machine is a leading equipment used in aluminum and steel door production. Generally, there are 2000T, 2400T, 2500T, 3000T, 3600T, 4500T, 5000T and other specifications. This hydraulic press is suitable for pressing door panels such as steel doors, anti-theft doors, interior doors, large iron doors, fire doors, etc. It is also suitable for levelling, flattening, stretching and other processes of steel plates.

The embossed forming of security doors is used for the front and back panels. Its main function is to increase the anti-theft strength and aesthetics of the door. The dimensions (length & width) of the parts that the hydraulic press can process for manufacturing aluminum and steel door skin are 2200mm & 520mm; the material is ordinary carbon steel, and the plate thickness is 0.4~0.8mm. The dimensions (length & width) of the forming mold are about 2400mm & 1450mm, and the thickness of the parts is 5~25mm, etc.

Our steel door embossing hydraulic press machine adopts an eight-column and three-beam structure with good anisotropic performance and precision retention. It is usually customized for users with non-standard, special-shaped, large-tonnage hydraulic press equipment. It is equipped with a PLC and servo system and has three operating modes: automatic/semi-automatic/manual, which can be set and adjusted through the touch screen. The cylinder adopts a double-cylinder or triple-cylinder layout to make the workpiece evenly stressed. Hydraulic pads and other components can be configured according to user needs.

Our stainless steel door embossing press machine can be used for pattern pressing and forming security doors, interior doors, large iron doors, aluminum doors, and stainless steel door panels. The 3000-ton steel door embossing hydraulic press machine can press door panels with iron plates less than 1.8mm and stainless steel door panels less than 1.2mm. At the same time, the pressure used also needs to be determined according to the complexity of the pattern. If the pattern is simple, the pressure is smaller; if the pattern is complex, the pressure required is larger.

1. The Structure of Steel Door Panel Embossing Press Machine

1) Main machine:

The machine body consists of an upper crossbeam, a movable crossbeam, a lower crossbeam, and eight columns. The main oil cylinder adopts a six-cylinder structure.

2) Hydraulic control system and electrical control system

This machine has an independent power mechanism and electrical system, centrally controlled by buttons and equipped with inching and semi-automatic working systems. This machine’s working pressure, pressing speed and stroke range can be adjusted arbitrarily within the specified range according to needs. It can also complete two process modes: fixed pressure forming and fixed stroke forming. Both process modes have a pressure-holding delay in semi-automatic operation after pressing and automatic return action. When the oil cylinder selection switch “inching/automatic” is turned to the “automatic” gear, press the “edge pressing cylinder down” button and the machine can realize: “edge pressing cylinder down-pressing-pressure holding—main oil cylinder down—-pressing to limit—main oil cylinder return to upper limit-edge pressing cylinder return, return to limit oil cylinder stop action, ejection cylinder ejects the workpiece and stops automatically.”

3) Cooling system

Our company provides two cooling systems: air cooling and water cooling.

◆ Air cooling uses a combination of finned radiators and axial fans. The oil flows through the finned radiator to dissipate heat. The axial fan drives the airflow to take away the heat, achieving the effect of heat dissipation.

◆ The water-cooled radiator uses circulating water to cool the oil. The water pipe is a tubular copper structure with good corrosion resistance and high thermal conductivity.

From the heat dissipation effect, the water-cooled radiator has a better heat dissipation effect than the air-cooled radiator, and users can choose it according to actual use. (If the user has higher heat dissipation requirements, air conditioning refrigeration can also be selected)

4) Safety protection system

To ensure users’ safe use of the press, extend the service life of user equipment and molds, and improve the quality of products. The machine is equipped with protection functions in hydraulic, mechanical and electrical procedures:

◆ The two-way hydraulic lock, ball valve, safety valve, etc., of the main cylinder’s lower chamber system ensures no upward movement of the movable crossbeam.

◆ The controllable main cylinder upper chamber pressure relief oil circuit ensures the qualified rate of user products.

◆ Multi-level pressure protection ensures the safe use of system pressure.

2. Advantages of Zhengxi’s Door Panel Embossing Hydraulic Press:

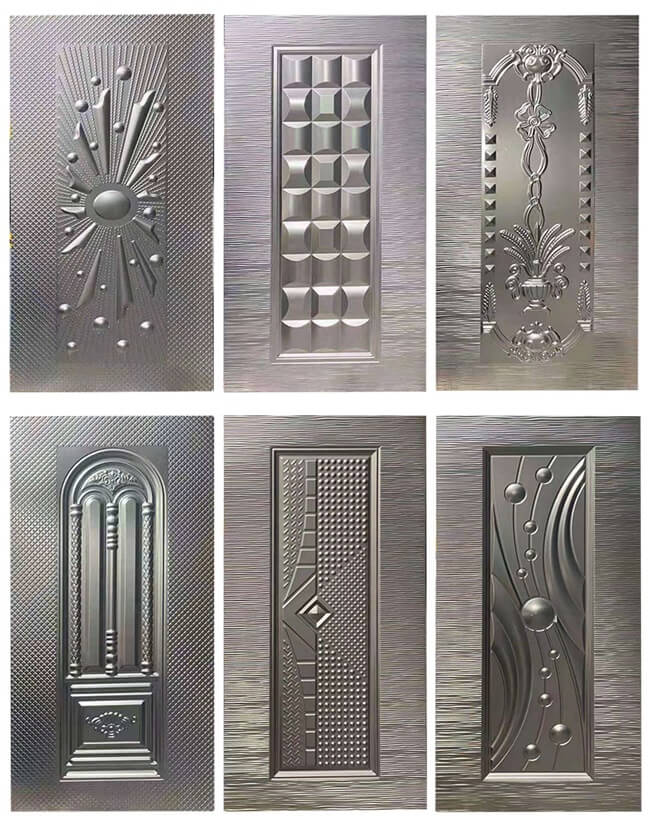

(1) Support customized matching standard molds. We have experience processing hundreds of anti-theft door facade patterns and moulds with wide varieties. We can also customize molds according to customer design requirements.

(2) The door panel embossing machine mold is divided into two parts: mold frame and mold core. When replacing, you only need to replace the mold core. The forklift mold change process only takes about 15 minutes, which is convenient and fast.

(3) You can choose an industrial touchscreen PLC control and servo system to improve production efficiency, save energy and reduce noise.

(4) The system pressure is adjustable. The pressure can be adjusted at any time according to the customer’s plate thickness and pattern to achieve the desired embossing effect.

(5) The hydraulic press for manufacturing aluminum and steel door skin can effectively reduce the harm of noise to operating employees.

3. Main Technical Parameters of 3000T Door Panel Embossing Press Machine

1) Nominal force: 30000KN

2) Return force: 435KN

3) Slider stroke: 500mm

4) Maximum working pressure of hydraulic system: 25MPa

5) Maximum distance between the lower plane of the slider and the working surface: 600mm

6) Slider stroke speed

◆ Fast down: 100-120mm/s

◆ Slow down: 7-12mm/s

◆ Return speed: 100-120mm/s

7) Workbench area: 2500 X 1500mm

8) Total power: 30KW+30KW=60KW

9) Plunger cylinder diameter: ZSG500 X500 X 6

10) Column diameter: 265mm X 4 pcs 195mm X 4 pcs

4. Optional Configurations for Door Panel Embossing Hydraulic Press:

✔ Touch screen industrial display

✔ Mobile workbench

✔ Hydraulic system heating and cooling device

✔ Photoelectric protection device

✔ Material punching device

✔ Mold heating and temperature control device

✔ Displacement sensor, pressure sensor

5. Key Points for Purchasing Hydraulic Press for Manufacturing of Aluminium and Steel Door Skin:

(1) Understand the size of the workbench and the actual working mode during the working process.

(2) Understand the equipment parameters. The parameters of the hydraulic press include the following aspects: hydraulic press workbench (note that it is the effective area where you place the mold), hydraulic press stroke, hydraulic press opening height, and span.

(3) It is necessary to consider whether the product design is reasonable, whether there is a pressure gauge, whether the pressure gauge switch design is reasonable, whether the overflow valve, motor, and oil pump are matched, etc.

(4) The appearance of the embossing machine for stainless steel door panels should be smooth and flat, and there should be no unspecified protrusions, depressions, rough surfaces, or other damage. The edges of the joint surfaces of the parts should be neat and symmetrical, and there should be no obvious misalignment. There should be no obvious gap between the door, cover, and joint surface. Exposed welds should be trimmed straight and even.

6. Operation Steps of Hydraulic Press for Door Panel Embossing

The embossing machine for stainless steel door panels is a specific direction equipment. It is designed for pressing and forming anti-theft doors and is highly efficient and targeted. It can also be applied to the pressing, bending, flanging, extrusion and other processes of plastic materials. This hydraulic press usually has high pressure and stroke, which can meet the door panel embossing process requirements. The operation steps of the hydraulic press for door panel embossing are as follows:

- Place the door panel to be embossed on the workbench and adjust its position to align it with the mold.

- Select the appropriate mold. According to the material and requirements of the door panel, select the appropriate mold for embossing.

- Adjust the pressure and stroke of the hydraulic press. According to the material and requirements of the door panel, adjust the pressure and stroke of the hydraulic press to ensure the quality and efficiency of embossing.

- Perform pre-pressing operation. Before formal embossing, the pre-pressing operation can be performed to check the fit between the mould and the door panel and adjust the pressure and stroke.

- Perform formal embossing operation. Follow the operating steps of the hydraulic press and perform formal embossing operations until the desired pattern effect is achieved.

- Stop the machine for cleaning. After the embossing operation is completed, stop the machine and clean the work area to ensure the safety of the machine and the work area.

It should be noted that when operating the door panel embossing hydraulic press, the hydraulic press should be operated according to the instructions for use, and attention should be paid to the maintenance and care of the machine to ensure its performance and life. In addition, when selecting the mold, the appropriate mold should be selected according to the material and requirements of the door panel to ensure the quality and efficiency of embossing.

As a hydraulic press manufacturer with over 20 years of industry manufacturing experience, Chengdu Zhengxi has always insisted on independent research development and design and can customize various hydraulic presses according to requirements. We are committed to providing customers with high-quality products and comprehensive after-sales guarantees. Welcome to visit our factory!