Titanium sponge is the main raw material for industrial titanium alloys. It has a loose, porous sponge appearance and needs to be melted and cast into titanium ingots and rods before it can be used. It can replace some steel materials and metallurgical steel. The processing of titanium sponges is inseparable from hydraulic press equipment. Titanium sponge can be pressed into the desired shape using a large titanium sponge hydraulic press.

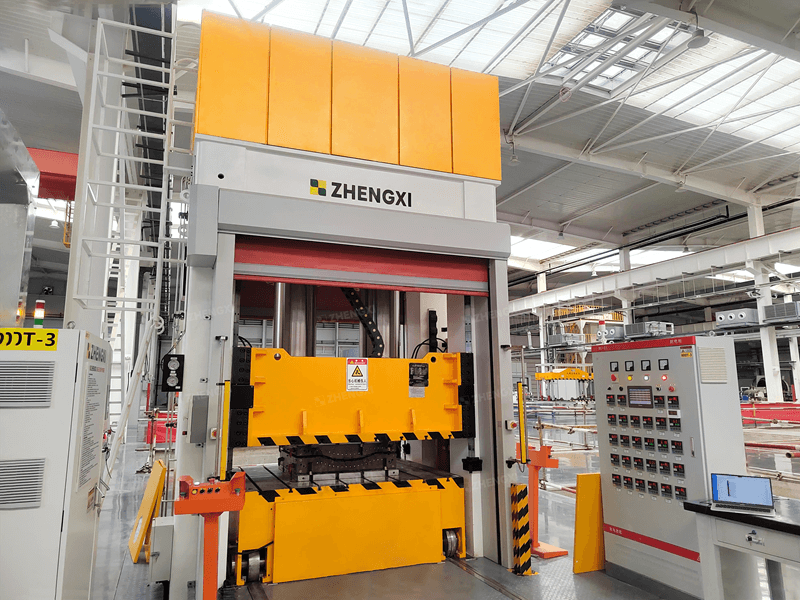

The titanium sponge hydraulic press adopts a four-column or frame structure. According to the specifications, density, process, etc. of titanium sponge products, Zhengxi Hydraulic can customize and produce titanium sponge compacting presses of various tonnages such as 2,000 tons, 5,000 tons, 8,000 tons, 10,000 tons, etc. for customers. The equipment’s opening, stroke, work surface size, etc. can be customized and produced according to customer needs.

Our 8,000-ton titanium sponge hydraulic press is easy to operate and maintain. In order to improve the machine’s anti-eccentric load capability and ensure the machine’s pressing accuracy, the slider guide adopts a large-section X-shaped guide rail guide. The operator can complete fully automatic pressing with one click through the fully automated design of the press. This large-scale forging equipment has reached an advanced level at home and abroad. It is an ideal large-scale hydraulic press equipment for pressing and forming sponge titanium electrodes.

The sponge titanium electrode extrusion forming automated production line independently developed by Zhengxi Hydraulics is currently one of the dedicated cold-forming extrusion production lines with the highest degree of automation and the most comprehensive application of CNC technology in the industry. The operator can use the fully automated operating system of the press to complete raw material input, particle size screening, color difference selection, multi-specification metering and proportioning, total quantity review, mixing, material receiving and feeding, electrode pressing, automatic discharging, and automatic palletizing and other operations. No manual intervention is required, effectively saving manpower.

Sponge Titanium Electrode Block Production Process

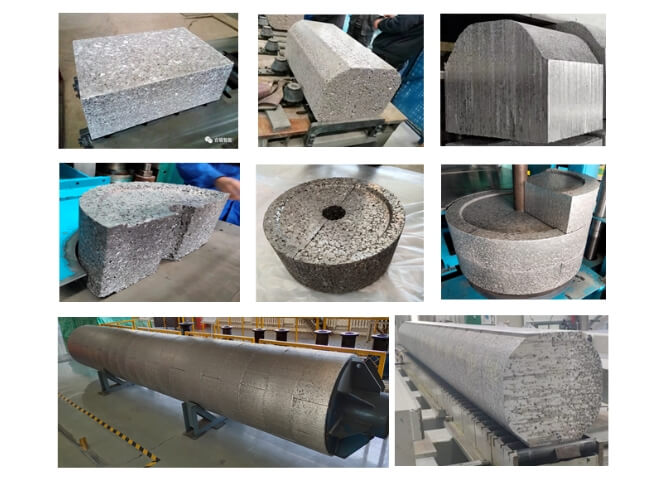

According to the melting characteristics of consumable furnaces, the forming process of titanium sponge electrodes is divided into axial pressing (such as fan-shaped, which can be clamped into a cylinder) and radial pressing (such as waist-drum type, rectangular parallelepiped, which can be clamped into an eight-sided imitation cylinder). Its production process mainly consists of raw material cloth, loading, pressing, unloading, palletizing, and other parts.

Features of Titanium Sponge Hydraulic Press

- The press body adopts a prestressed frame structure, and its strength and stiffness are calculated through finite element analysis.

- The entire set of equipment has achieved a standardized design and has a high degree of modularity. It is reliable and efficient.

- The main power drive of the equipment is equipped with a servo motor and servo control system. Servo motors greatly save electrical energy consumed during equipment production. The motor makes little noise. The pressure is controlled by servo monitoring in a closed loop, with high control accuracy.

- The hydraulic system uses imported high-quality components. Action control is convenient, flexible, safe, and reliable.

- The electronic control system is equipped with a Siemens PLC touchscreen centralized control panel. Equipped with pressure display, pressure curve, displacement display, oil temperature alarm, temperature curve, filter element alarm, and emergency stop device.

- Adopt a servo CNC high-speed feeding device. The granular titanium sponge and master alloy are automatically and completely fed into the mold cavity. Smooth operation and high conveying efficiency.

- Adopt an automatic discharging and palletizing system. The formed electrode blocks are fully automatically discharged and stacked according to subsequent production needs. It has a high degree of automation.

- Automated control system integrates process optimization, equipment monitoring, and fault diagnosis, and can perform data exchange.

Technical Parameters of Titanium Sponge Compacting Hydraulic Press

| Main parameters | Unit | |||

| Nominal force | T | 4500 | 7000 | 10000 |

| Slider stroke | mm | 1000 | 1300 | 1500 |

| Slider Speed – Fast Down | mm/s | 80 | 80 | 80 |

| Slider Speed – Return | mm/s | 80 | 80 | 80 |

| Maximum closed height | mm | 2500 | 3000 | 4000 |

| Effective area of workbench (left and right x front and back) | mm | 1300×1300 | 1500×1500 | 1800×1800 |

Application of Titanium Compacting Press

The titanium sponge hydraulic press is used for pressing and forming electrodes of sponge and granular rare metals such as titanium sponge and zirconium sponge. The pressed electrodes are used to produce titanium and titanium alloys, zirconium and zirconium alloys. It is widely used in aerospace, nuclear power, and other fields.

The titanium sponge compacting hydraulic press designed and produced by Zhengxi Hydraulic has the characteristics of stable pressure, reliable mechanical performance, and high machine pressing accuracy. We are a professional hydraulic press factory that provides highly matching hydraulic press solutions for titanium sponge compaction. If you have any needs, please contact us.