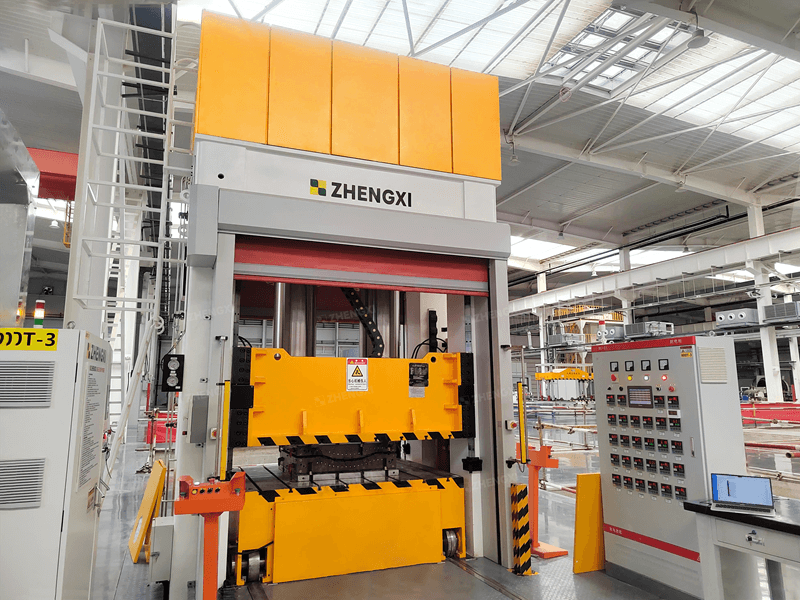

The stainless steel pot stretching hydraulic press is also known as the stainless steel product stretching machine, hydraulic stretching machine, metal deep drawing hydraulic press, etc. This machine is a conventional 400-ton frame hydraulic press produced by Chengdu Zhengxi Hydraulic Press Factory for customers. The oil circuit of the equipment is controlled by a cartridge valve. It has a simple, compact structure, sensitive and stable action, and can realize a cycle of automatic process actions.

The 400-ton stainless steel pot forming hydraulic press consists of two major parts: the main machine and the control mechanism. It is connected to form a whole through pipelines and electrical devices. The main machine part includes the fuselage, main cylinder, limiter, etc. The control mechanism includes a hydraulic pump station (power system), an electrical box, a mobile console, etc. It is widely used in fastener factories, automobile repairs, the hardware industry, auto parts companies, mining, electronic components, watch straps, jewelry, lighting, lighting, mobile phone housings, pumps, electrical equipment and other industries.

Stainless steel deep drawing hydraulic press generally adopts a three-beam four-column structure, and there are two types: deep stretching and shallow stretching.

Shallow stretching is suitable for stretching and forming stainless steel dinner plates, shallow stainless steel ladles, and other similar products; hydraulic pads are not required.

Deep stretching is suitable for: buckets, rice cooker liner, etc.

Structural Features of 400-ton Stainless Steel Pot Forming Hydraulic Press

1. Body

The 400-ton hydraulic press uses a galvanized sheet as the base plate. The workbench and slider are integral 45# cast steel. The galvanized sheet is the base plate, and high-quality environmentally friendly polyester paint is used as the topcoat.

2. Main cylinder

The hydraulic press cylinder is made of 45# steel, which is processed after forging to extend the machine’s service life.

3. Hydraulic system

The 400-ton stainless steel pot forming hydraulic press adopts a large flow cartridge valve. An oil suction filter is set at the oil inlet of the pump to prevent impurities from entering the hydraulic system to ensure the normal operation of the oil circuit. The system has oil temperature and oil level display, air filter and other devices. The oil tank is a steel plate welding structure, and the bottom is equipped with a screw plug for draining oil and sewage. Plug-in hydraulic special motor reduces workshop noise.

4. Electrical system

The four-column hydraulic press has an independent electrical control box that centrally controls its operation. It also has a photoelectric protection device and an emergency stop button to ensure the safety of personnel and equipment during operation.

5. Operating system

The 400-ton hydraulic press adopts a PLC programming system to achieve free switching between automatic and semi-automatic operation modes, which is convenient for equipment maintenance. The equipment operation speed and main cylinder pressure can be adjusted arbitrarily. It meets the process requirements of fixed stroke and fixed pressure during production.

Working Mode of Stainless Steel Pot Forming Hydraulic Press

- Inching: Press the corresponding button to produce the corresponding action, and release it to stop the action

- Manual: Press the corresponding button to produce the corresponding action until the limit position

- Semi-automatic:

(1) Constant pressure control: the sliding beam descends quickly, descends slowly, pressurizes to the upper limit of the electric contact pressure gauge DJ, then maintains the pressure for a delay, releases the pressure, and returns (then stops)

(2) Constant stroke control: the sliding beam descends quickly, descends slowly, pressurizes (when the sliding beam touches the proximity switch XK, a signal is sent to start the pressure maintenance delay), releases the pressure, and returns (then stops)

Applicable Fields of 400T Stainless Steel Pot Forming Hydraulic Press

400-ton stainless steel pot hydraulic press is suitable for various plastic material pressing processes, such as stamping, bending, flanging, thin plate stretching, forming, punching, bending, etc. It can also be used for correction, press fitting, grinding wheel forming, and pressing and forming of plastic products and powder products.

- Auto parts: body panels, brake pads, fuel tanks, chassis, bridge housings, bumpers.

- Household appliances: washing machines, rice cookers, televisions, refrigerators, air conditioners and other parts.

- Kitchen appliances: sinks, pots, and other containers.

Optional Accessories for Stainless Steel Stretching Hydraulic Press

- Mobile workbench;

- Punching buffer device;

- Photoelectric protection device;

- Stroke, pressure, speed digital display, CNC device;

- Touch-type industrial display screen;

- Hydraulic system heating and cooling device;

- Punching device;

- Slider safety bolt;

- Mold heating and temperature control device;

- PLC programmable controller

A customized deep-drawing hydraulic press requires users to provide us with the size, material and special requirements of the workpiece to be processed so that we can calculate the tonnage of the required hydraulic press more accurately. Choose Chengdu Zhengxi Intelligent Equipment Co., Ltd. for a customized stainless steel deep drawing press.