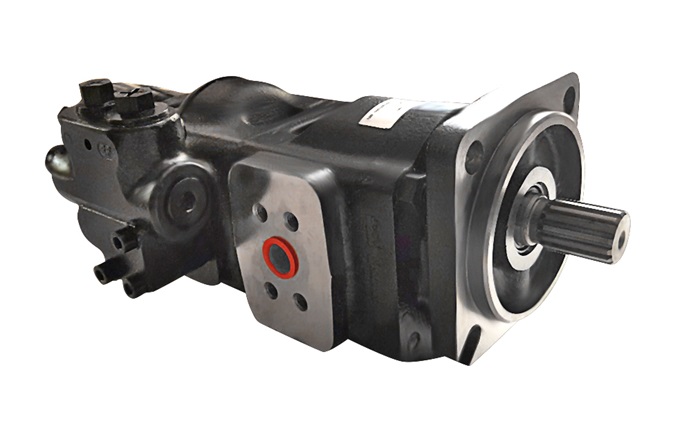

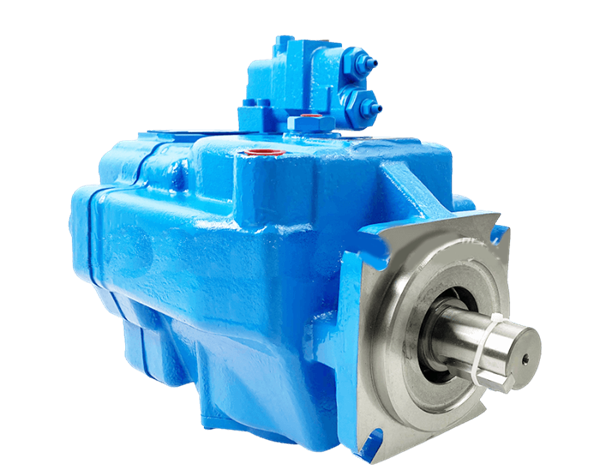

The hydraulic pump is an energy conversion device whose function is to convert the prime mover’s mechanical energy into the hydraulic oil’s pressure energy, thereby providing the hydraulic system with hydraulic oil with a constant pressure and flow rate.

As the power source of the hydraulic system, the normal operation of the hydraulic pump is crucial, and its performance directly affects the reliability and stability of the hydraulic system.

However, due to the large workload, high speed, and various control methods of the hydraulic pump, it is prone to various failures. If the hydraulic pump does not work properly, the entire hydraulic system cannot operate.

This article mainly analyzes the common types and causes of hydraulic pump failures. It explores solutions to common hydraulic pump failures to provide help for the efficient use and rapid maintenance of hydraulic pumps.

1)Hydraulic pump oil discharge failure

If the hydraulic pump does not discharge oil or the amount of oil discharged is insufficient, it will affect the operating speed of the actuator. There are 5 common causes of failure.

- The inlet and outlet of the hydraulic pump are installed in reverse, or the direction of the pump is inconsistent with the direction of the external motor.

- Insufficient oil in the oil tank. The oil level is too low, resulting in discontinuous oil suction.

- The oil suction pipeline’s oil filter is blocked, or the oil filter hole is too small, resulting in a large oil suction resistance.

- The hydraulic pump is poorly sealed, air enters, causing oil suction difficulties, or the connection between the hydraulic pump and other components is loose, resulting in increased leakage.

- The oil temperature is unsuitable, resulting in difficulty in pumping oil. The oil viscosity decreases when the temperature is too high, resulting in serious internal leakage. When the oil temperature is too low, the oil viscosity is too high, resulting in the hydraulic pump being unable to suck out the oil.

In response to the above problems, the following solutions are proposed.

- Reinstall the hydraulic pump and check whether the motor direction is consistent with the direction requirements on the hydraulic pump nameplate. If not, adjust as required.

- Add hydraulic oil in time to ensure the tank’s amount meets the requirements.

- Clean the oil filter on time or select an oil filter with a strong passing capacity to meet the work needs.

- Check the sealing performance of the hydraulic pump, replace severely worn parts, check the joints between the hydraulic pump and other components, and ensure that all fasteners are connected normally.

- Select hydraulic oil with appropriate viscosity or add a device to control the oil temperature in the hydraulic circuit.

2)Hydraulic pump pressure failure

Insufficient oil delivery pressure of the hydraulic pump will cause the actuator to operate weakly. Common reasons are:

- The pressure gauge is not open or faulty.

- The hydraulic pump parts are seriously worn, resulting in aggravated internal leakage.

- The hydraulic oil temperature is too high, resulting in low oil viscosity and increased leakage;

- The safety valve setting value is too low, or the valve core is stuck in the open overflow position.

- The motor speed is not enough.

In response to the above problems, the following solutions are proposed:

- Check and confirm whether the pressure gauge can work normally.

- Repair the hydraulic pump, replace and repair the worn parts, or send it directly to the factory for inspection.

- Select hydraulic oil with appropriate viscosity or add a device to control the oil temperature in the circuit.

- Check the safety valve and reset its pressure value.

- Adjust the motor so that its speed is within the working requirements of the hydraulic pump.

3)Hydraulic pump noise or vibration is abnormal

When the hydraulic pump is working, there is noise or severe vibration. The reasons may be as follows:

There is air inside the hydraulic pump, or the liquid level in the oil tank is low, causing the pump to inhale air.

The pump shaft is not concentric with the external motor shaft.

There are many impurities in the oil, which is seriously polluted.

The internal parts of the hydraulic pump are damaged or worn.

The diameter of the hydraulic pump suction pipeline is too small. The pipeline is too bent, there are too many dead corners, or the oil filter is blocked, resulting in insufficient oil suction.

In response to the above problems, the following solutions are proposed:

Check whether the hydraulic pump and the pump are connected with other components normally to prevent the fasteners from loosening and inhaling air. At the same time, check the height of the oil tank liquid level to avoid the oil level in the oil tank being too low.

Adjust the coaxiality of the pump shaft and the motor shaft as required.

Check the cleanliness of the oil on time and replace clean hydraulic oil on time.

Repair the hydraulic pump, replace worn parts, or send it directly to the factory for inspection.

Select the appropriate suction pipe diameter according to the requirements, try to reduce the bends during installation, and clean the oil filter in time.

4)Hydraulic pump heating failure

Common reasons for abnormal heating of the hydraulic pump or excessive oil temperature are as follows:

- The installation clearance of the hydraulic pump components is too small, resulting in severe friction and heating. The clearance of some sliding surfaces of the hydraulic pump is ample, the internal leakage increases and the lost pressure and flow are converted into heat energy and heat.

- The pump has been working for a long time under conditions close to or exceeding the rated pressure, or the pressure control valve fails, failing to unload and heat.

- The return oil is sucked into the hydraulic pump without being cooled by the oil tank.

- Air or moisture is mixed in the oil. When the hydraulic pump absorbs or discharges oil, air, and moisture, it will cause the oil temperature to rise rapidly.

- The oil is contaminated and seriously deteriorates, resulting in the pump’s large oil suction resistance.

In response to the above problems, the following solutions are proposed:

- Measure the size of the assembly clearance of each part during assembly to ensure that the matching clearance is within the specified range.

- In each working cycle of the hydraulic pump, the working condition exceeding the rated pressure should not exceed 6s as much as possible.

- Separate the return oil port from the pump inlet by a distance and set a baffle in the oil tank.

- Check the relevant sealing parts and seal them strictly according to the requirements.

- Replace the clean hydraulic oil.

5)Severe oil leakage in the hydraulic pump

Common causes of oil leakage are:

- Loose connection of hydraulic pump inlet and outlet.

- Severe wear of hydraulic pump parts or improper installation leads to increased clearance.

- Aging, damage, deterioration, or incorrect seal specifications of seals in pipeline connection parts lead to poor sealing, which increases leakage.

- The oil temperature is too high, and the oil viscosity is reduced.

- Pipeline stress is not eliminated, and the seal has poor contact.

In response to the above problems, the following solutions are proposed:

- Tighten the pipe joints or screws to ensure that the inlet and outlet are tightly connected.

- Repair the worn parts or directly replace the damaged parts to ensure that the clearance of the hydraulic pump is normal.

- Check and replace suitable seals to ensure good sealing.

- Replace oil with high viscosity or add an oil temperature control device to ensure that the oil viscosity meets the requirements.

- Eliminate pipeline stress and replace parts with good sealing.

As a professional hydraulic press manufacturer in China, Zhengxi provides high-quality hydraulic press machines and related knowledge. If you have any needs, contact us!