Plate heat exchanger hydraulic press is used for high-density corrugated shallow drawing and forming, such as stainless steel, and titanium plate heat exchanger plates. The frame and main oil cylinder of the equipment adopt high-strength steel wire prestressed winding technology, and the structural design has a high safety factor.

The hydraulic system of the hydraulic plate heat exchanger presses is mainly composed of the main system, the ultra-high pressure control system, and the auxiliary control system. Various special ultra-high pressure valve groups are adopted through reasonable system design and configuration. It can maximize energy utilization and achieve low consumption and high efficiency. The electrical system controls each working state of the press through an independent PLC, including the operating system, safety system, and status self-inspection system.

Our hydraulic presses are widely used in the press forming of large heat exchanger plates. It mainly adopts a prestressed steel wire winding structure, with an independent electrical control system and hydraulic system. The electrical control system adopts PLC control and is equipped with a touch-mode display screen. Both manual and semi-automatic operating procedures can be realized. Zhengxi’s heat exchanger plates forming hydraulic press can realize blanking and punching at one time. Its production line is domestically and internationally advanced press-forming equipment for heat exchanger plates and thin plates.

Zhengxi‘s heat exchanger plate hydraulic press production line is easy to operate, saves manpower, and has precise pressing. It can greatly improve the plate pressing efficiency.

Characteristics of Hydraulic Plate Heat Exchanger Presses

- This machine is a large-tonnage steel wire winding hydraulic machine, which adopts an upper and lower pressure structure of the oil cylinder. The main oil cylinder and frame adopt a prestressed steel wire winding structure, which has the characteristics of high fuselage strength, high-pressure bearing, and good fatigue life. It is mainly used in the pressing, embossing, and pressing of metal sheets.

- Hydraulic control adopts a cartridge valve integrated system. Reliable action, long service life, small hydraulic shock, less connecting pipelines, and leakage points.

- Centralized control with buttons, with two control modes of adjustment and a single-hand cycle.

- Independent electrical control system, reliable operation, intuitive action, and convenient maintenance.

- By selecting the operation mode, two forming processes of fixed distance and constant pressure can be realized, and it has the performance of maintaining pressure and delaying time.

- The working pressure and stroke can be adjusted within the specified range according to the process requirements

Advantages of Zhengxi Plate Heat Exchanger Hydraulic Press

- The prestressed steel wire winding technology makes the large tonnage press small in size.

- High fatigue resistance, long service life, and high pressing precision of the press.

- Zhengxi has more than 20 years of experience and history in the use of prestressed winding technology and ultra-high pressure technology, which are applied to precision molding in various fields.

Application of Stamping Hydraulic Press for Heat Exchanger Plates

The plate is the core component of the plate heat exchanger. In order to make the fluid evenly flow through the plate surface, increase the heat transfer area, and promote the turbulence of the fluid, the plate surface is often punched into a concave-convex corrugated shape. There are dozens of corrugation shapes, and the commonly used corrugation shapes include horizontal corrugation, herringbone corrugation, and circular arc corrugation. The heat exchanger plate hydraulic press is specially designed for the production of heat exchanger plates.

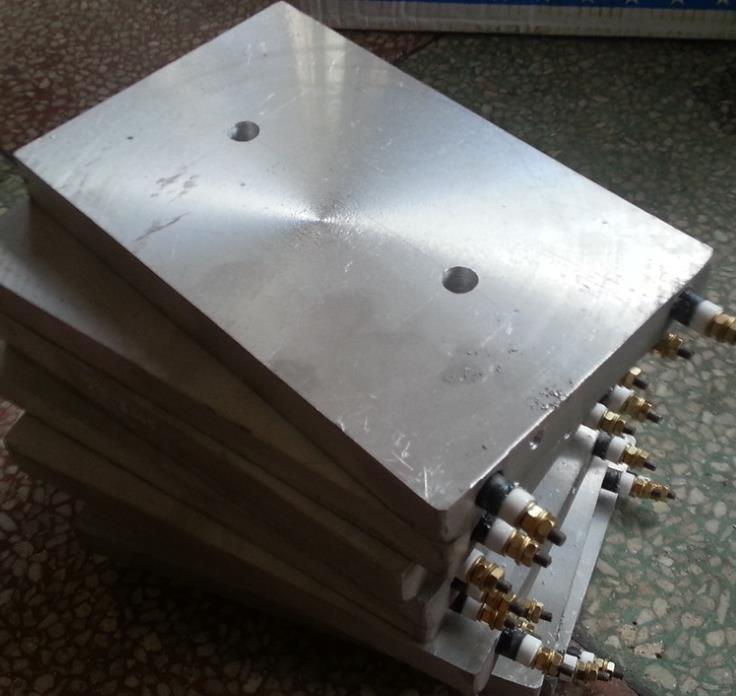

Our heat exchanger plates forming hydraulic presses are mainly used for high-pressure pressing of large metal and non-metal plates, such as titanium plates, stainless steel heat exchanger plates, etc. They are mainly suitable for shallow stretching and shaping processes of plate heat exchangers. Zhengxi can customize 1000-20000 tons of super large tonnage heat exchanger plate hydraulic press.

Optional Accessories

- Servo motor drive, oil heating or cooling device

- Displacement sensing device

- Touch industrial display screen

- PLC programmable controller

- Floating guide rail and rolling bracket for mold change

- Mold lighting

- Mold quick clamping mechanism

- Light curtain safety protection device

Technical Parameters of the Plate Heat Exchanger Hydraulic Press

| Model | Unit | KR-3000 | KR-4000 | KR-6000 | KR-10000 | KR-20000 |

| Nominal force of master cylinder | Ton | 3000 | 4000 | 6000 | 10000 | 20000 |

| MAX liquid pressure | Mpa | 90 | 90 | 90 | 90 | 90 |

| MAX master cylinder stroke | mm | 250 | 250 | 250 | 300 | 300 |

| Master cylinder quick down speed | mm/s | 30 | 30 | 40 | 60 | 60 |

| Master cylinder working speed | mm/s | 0.4-0.8 | 0.4-0.8 | 0.4-0.8 | 0.4-0.8 | 0.4-0.8 |

| Master cylinder return speed | mm/s | 30 | 30 | 40 | 60 | 60 |

| Workbench opening height | mm | 500 | 550 | 550 | 600 | 600 |

| Workbench (effective area) left and right * front and rear | mm | 1000*1600 | 1100*1800 | 1300*2300 | 1600*2500 | 1700*3200 |

| Machine dimensions(left-right) | mm | 1750 | 1800 | 2100 | 2500 | 3000 |

| Machine dimensions(before-after) | mm | 1600 | 1800 | 2500 | 2500 | 3200 |

| Machine dimensions(height) | mm | 3900 | 3900 | 4300 | 5200 | 6100 |

| Motor power | kw | 18.5 | 22 | 45 | 55 | 60 |