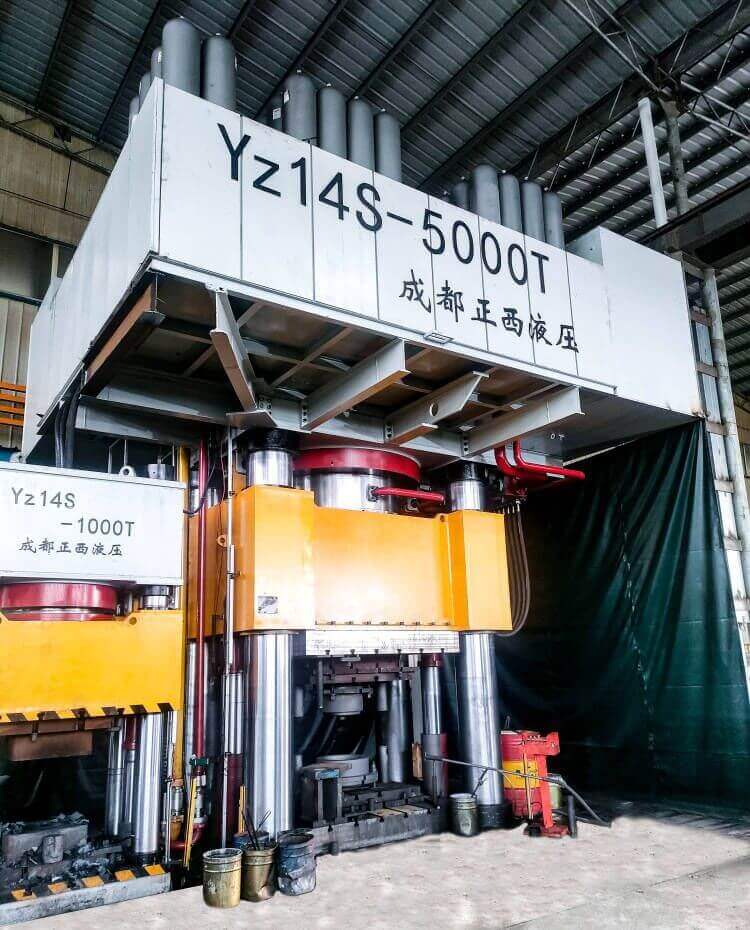

Hot Forging Hydraulic Press

Hot Forging Press for Sale

Hot forging hydraulic press is a hydraulic press for forging hot metal. It adopts a forging method in which the metal blank is heated to a temperature above 1000°C, and then the metal is plastically formed into the shape and size of the forging by using a mold. There are four-column and frame styles.

- Realize multiple functions such as fast forging, constant forging, and pressure holding.

- Meets the requirements of forging processes such as upsetting, elongating, punching, horse bar reaming, and shifting.

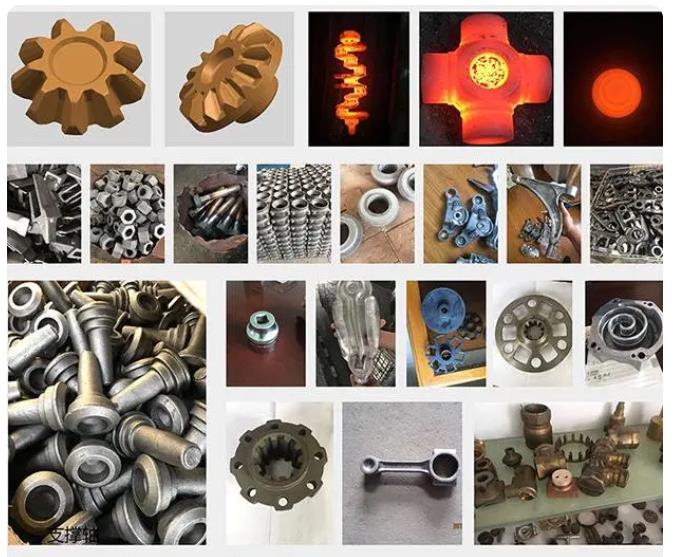

- Mainly suitable for the forging production of all kinds of special-size forgings, shafts, discs, and special-shaped parts, such as bearing inner rings, flanges, half shafts, joints, crossheads, hubs, train wheels, etc.

Video

Watch the video below to learn more details.

Hot Forging Press Features

1. Stable performance, strong rigidity, accurate positioning. Four-column structure, compact structure, small footprint, convenient hoisting and transportation, economical and practical.

2. High-quality steel castings and high-toughness columns can ensure long-term work without deformation and fracture.

3. The hydraulic system adopts the integral cartridge valve integrated system, which has a small impact, no noise, stable quality, and improves the service life of the equipment.

4. The hydraulic cylinders, hydraulic valves, and hydraulic pumps of the 5,000-ton hot forging press machine adopt well-known brands to ensure long-term trouble-free production.

5. The electrical system adopts a CNC PLC program controller, which is simple and convenient to operate. And the system pressure, pressure holding time, and working mode can be adjusted according to the production process.

6. The hydraulic system is perfectly integrated with the electrical system, and safety devices are installed. If any link fails, the hot forging hydraulic machine will be shut down immediately without causing loss.

7. Regardless of press fitting, pressure forming, or calibration, it can be done with one piece of equipment. And the working pressure can be achieved by simply changing the mold and without purchasing equipment again.

Application of Hydraulic Hot Forging Press

Hot forging hydraulic presses can produce a large number of solid metal parts of aluminum alloys, copper alloys, steel, or superalloys with irregular shapes and good mechanical properties, such as piston rods, universal joint forks, excavator forged buckets teeth, forged gear transmission parts, forged blanks for transmission machinery, transmission forgings, electric power fittings blanks, sprocket blanks, mining machinery forgings, valve body blanks, gear blanks, shafts Blanks, flange blanks, bolt and nut forgings, locks. Zhengxi is a professional forging press manufacturer in China that provides high-quality hot forging machines. Contact us to know more!

Four-column Types Parameter

Model |

Unit | Specification model | ||||||

800T | 1000T | 1600T | 2000T | 2500T | 3150T | |||

Nominal force | KN | 8000 | 10000 | 16000 | 20000 | 25000 | 31500 | |

Max.liquid Working pressure | Mpa | 25.0 | 25.0 | 25.0 | 25.0 | 25.0 | 25.0 | |

Pressure Classification | KN | 8000 | 10000 | 8000/16000 | 10000/20000 | 10000/5000/25000 | 1000/2000/31500 | |

Max.Open Height | mm | 2500 | 2600 | 2800 | 2800 | 3200 | 3600 | |

slider stroke | mm | 1200 | 1400 | 1600 | 1600 | 2000 | 2000 | |

Centre Distance Of Columns | mm | 2200*1100 | 2200*1100 | 2500*1200 | 2500*1200 | 3300*1600 | 3400*1600 | |

Distance Of Columns | mm | 240 | 260 | 340 | 200 | 420 | 440 | |

Moving Table Size | L-R | mm | 1500 | 1500 | 1800 | 1800 | 2000 | 2000 |

F-B | mm | 3000 | 3000 | 3600 | 3600 | 5000 | 6000 | |

Height | mm | 220 | 250 | 520 | 250 | 300 | 300 | |

Moving Table Procedural Place | mm | 3 | 3 | 3 | 3 | 3 | 3 | |

Foring Eccentricity | mm | 100*60 | 100*60 | 140*70 | 140*70 | 150*100 | 200*120 | |

Slider speed | Down | mm/s | 400 | 400 | 400 | 400 | 400 | 400 |

Pressing | mm/s | 60 | 60 | 120/60 | 120/60 | 140/100/60 | 140/100/60 | |

Return | mm/s | 250-400 | 250-400 | 250-400 | 250-400 | 250-400 | 250-400 | |

Moving table speed | mm/s | 200 | 250 | 200 | 200 | 200 | 200 | |

Times of quick-forging | once/min | 50-60 | 50-60 | 50-60 | 50-60 | 50-60 | 50-60 | |

Main motor power | KW | 440 | 380 | 850 | 1000 | 1350 | 1650 | |