products

composite hydraulic press

The composite hydraulic press mainly undertakes the molding process in the production process. It uses various special-shaped molds to form through high pressure and thermosetting. According to different molds and product formulas, composite material products of various shapes, colors and strengths can be manufactured by using a composite press machine.

deep drawing hydraulic press

The hydraulic deep drawing press is the basic hydraulic machine for sheet metal forming. It is a hydraulic press machine specially designed and manufactured for the industries of aluminum, copper products, stainless steel, and thin iron products, especially suitable for deep drawing of thin plates and press forming of stainless steel and thin plates.

powder compacting hydraulic press

Powder compacting hydraulic press, as the name suggests, is to aggregate various powdery substances into solids of a certain shape (group, ball, block, cake, etc.) through the cooperation of the mold and under the pressure of the hydraulic press. It is mainly suitable for the molding process of powder, granules, fiber, and other materials, including the compression molding of cattle and sheep salt bricks, metal powder, ceramic powder, fish bait, nutrient soil, bath salt balls, medicinal powder, tea, seaweed, etc.

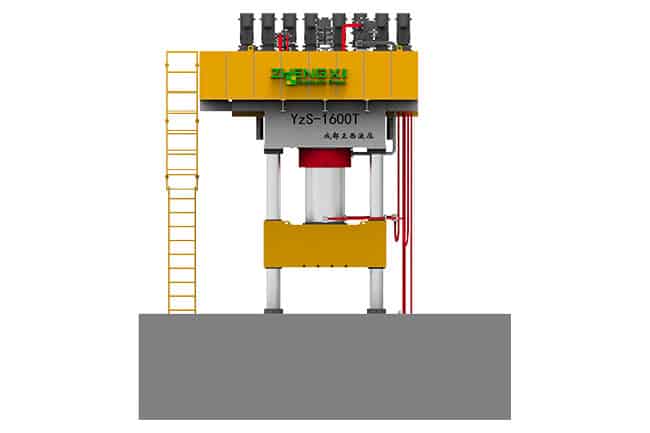

forging hydraulic press - hot/ cold/die

Forging hydraulic press is a forging equipment that can complete various free forging processes, and is one of the most widely used equipment in the forging industry. It is divided into four prestressed combined frame type and two-column brake prestressed combined frame type. It has the advantages of fast speed, high precision, energy saving and environmental protection, and high degree of automation.

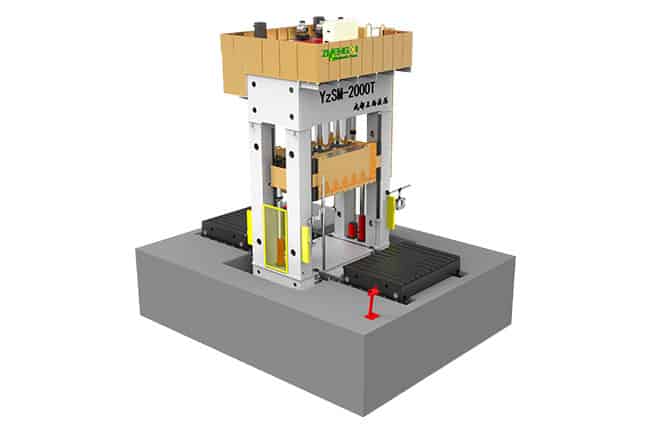

four-column hydraulic press

Four-column hydraulic press is a kind of mechanical equipment that uses the static pressure of hydraulic oil delivered by the oil pump to process metal, plastic, rubber, wood, powder and other products. It is often used in pressing process and pressing forming process, such as: forging, stamping, cold extrusion, straightening, bending, flanging, sheet drawing, powder metallurgy, press fitting, etc.

c frame hydraulic press

C frame hydraulic press is also called single-column hydraulic press. The fuselage structure of this machine is a C-shaped single-arm structure. The whole machine is welded by CO2 of all steel plates. After welding, it is tempered and aged to ensure that the fuselage will never deform. This hydraulic press machine has high strength, stable precision, and long-term retention.

h frame hydraulic press

The H-frame press is a smaller type of press, which is more convenient to carry and use. It adopts a double-column structure, which is simple, economical, and practical. The H-frame hydraulic press machine is equipped with a hand pump and is generally used for small-batch production.

Press Line Automation

With many years of experience in the field of hydraulic press, Zhengxi provides dozens of press line automation for customers and is well accepted by all customers. In the press system, the real-time synchronous control system developed by Zhengxi, realizes synchronous control, real-time position monitoring, and following, and safe interlock between the robot and the press, robot and robot, thus maximizing the production efficiency.