Forging Press Line

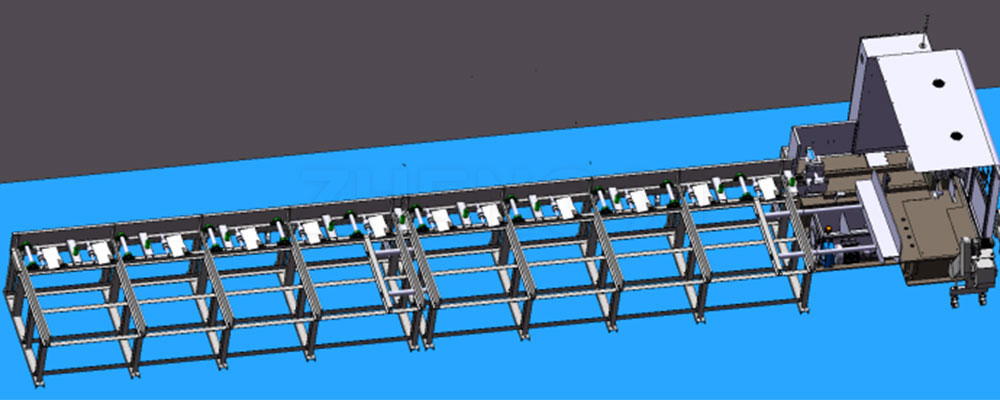

1.Raw Material Cutting

This cutting system adopts automatic cutting. Automatically cut square raw material to nominal length. The production of this project uses AISI9260 hot-rolled square steel. Maximum cutting speed, 20-30 seconds for one piece.

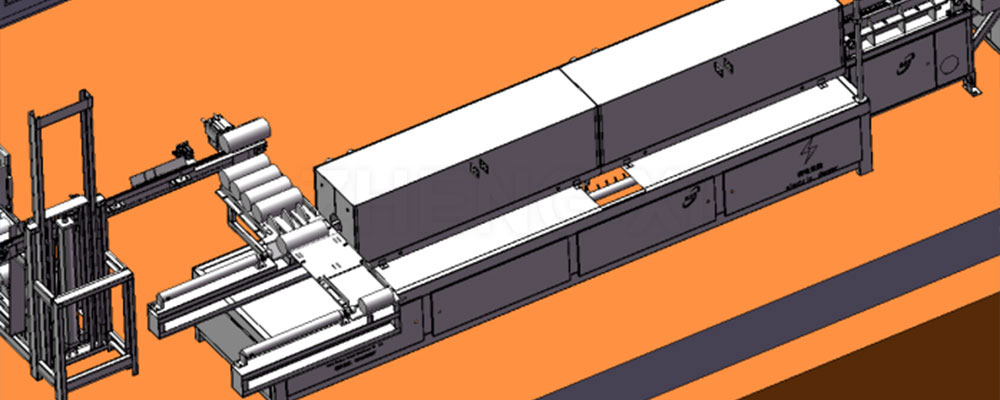

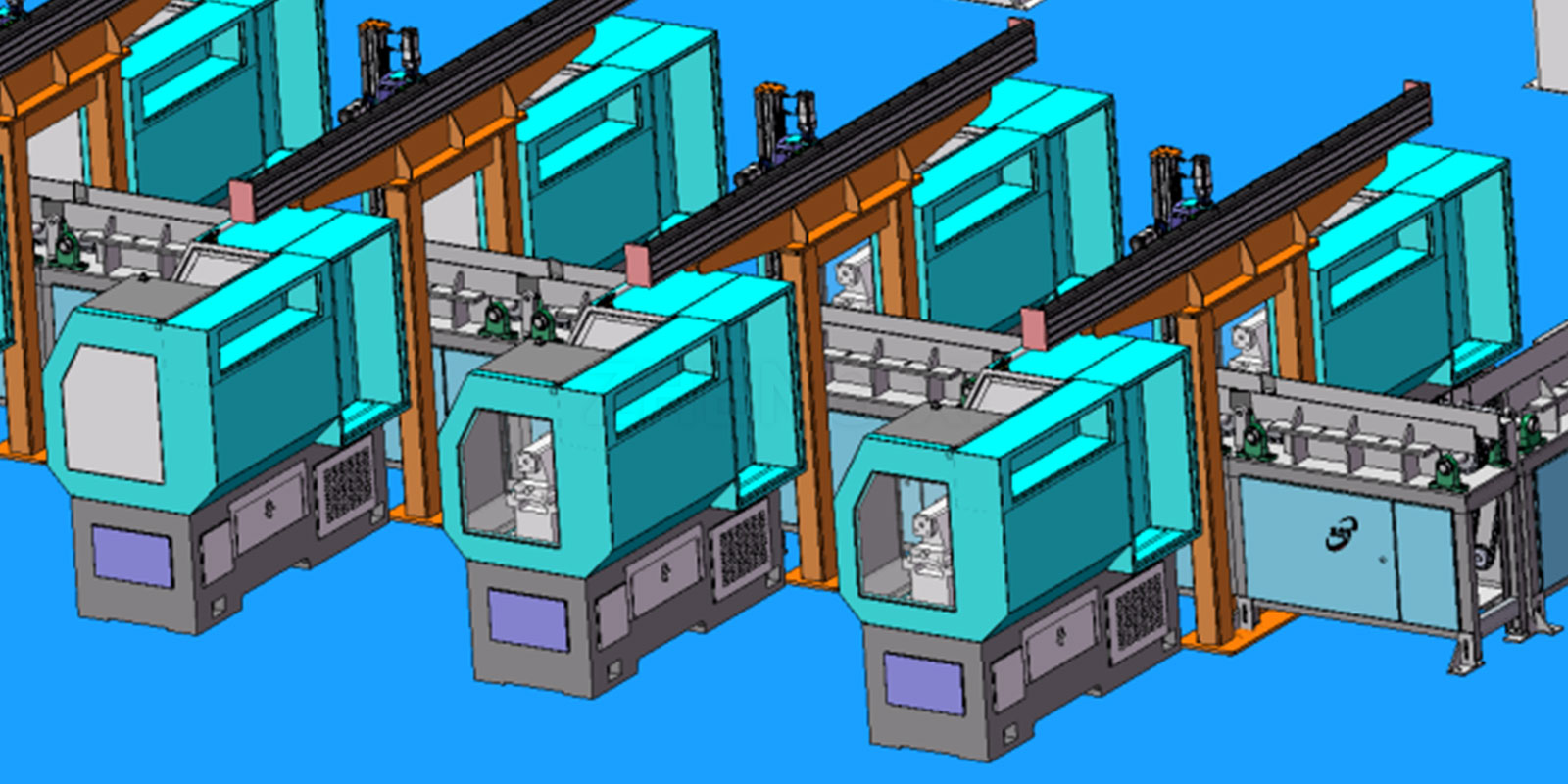

2.Feeding and Heating

Use the elevator to transport the raw materials to the predetermined location, and then transfer the raw materials to the entrance of the heating equipment through the chain.

The raw material is pushed into a furnace by an air cylinder and then heated up by the furnace.

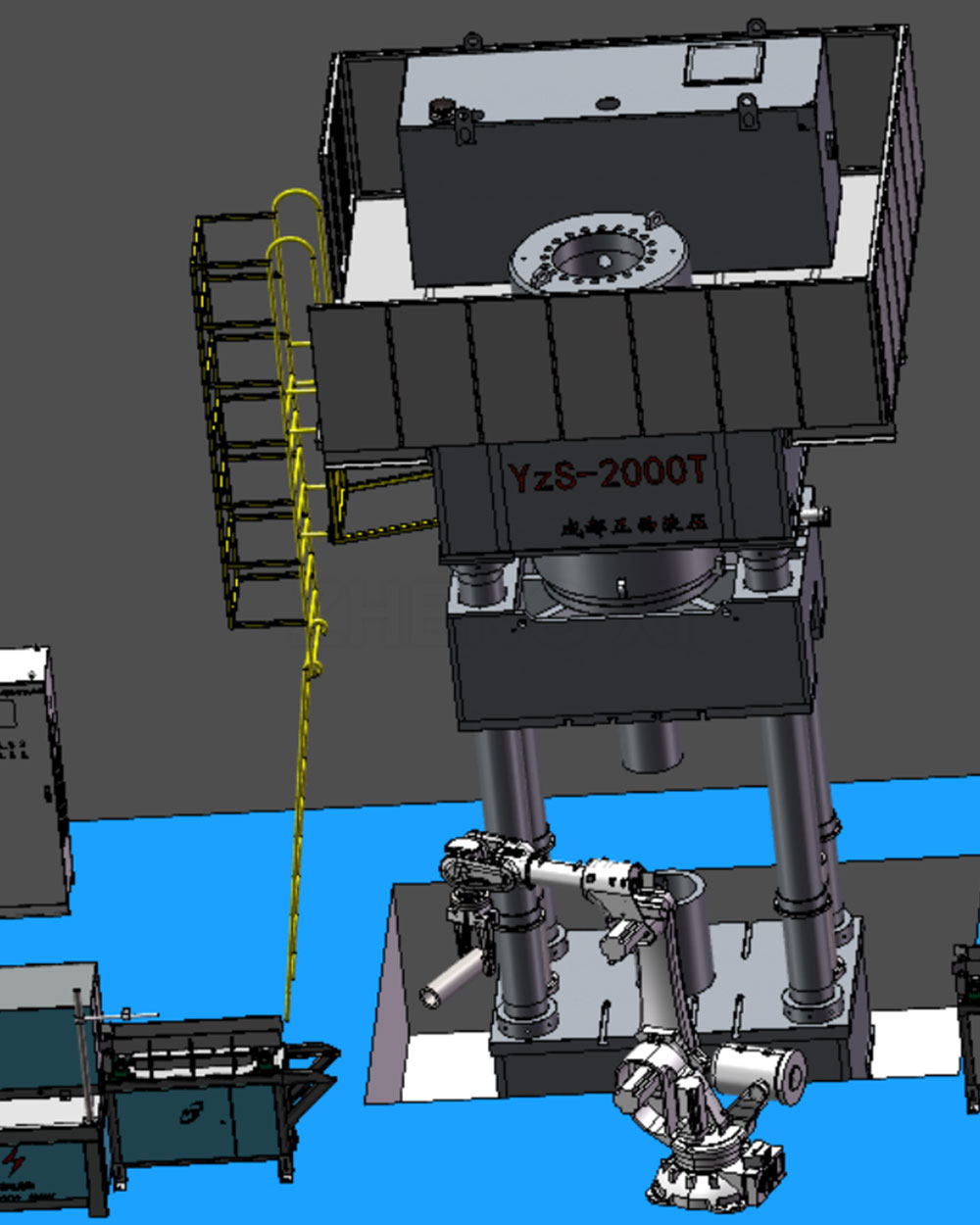

3.Forging Hydraulic Press

Our 2000-ton forging press has the advantages of fast forging speed, high forging precision, strong anti-eccentric load capacity, and a high degree of automation. The company can design and customize the four-column and frame structures as needed.

Parameter of 2000T hot forging press

| NO | Item | Unit | Technical parameter | |

| 1. | Model | / | YzS-2000T | |

| 2. | Nominal force | KN | 20000 | |

| 3. | Max. liquid pressure | MPa | 25 | |

| 4. | Structure type | / | 4 column | |

| 5. | Daylight | mm | 2900 | |

| 6. | Max. ram stroke | mm | 1800 | |

| 7. | Ram speed | Down | mm/s | 300 |

| 8. | Worktable size | Pressing | mm/s | 6-120 |

| Return | mm/s | 250 | ||

| LR | mm | 1600 | ||

| FB | mm | 1600 | ||

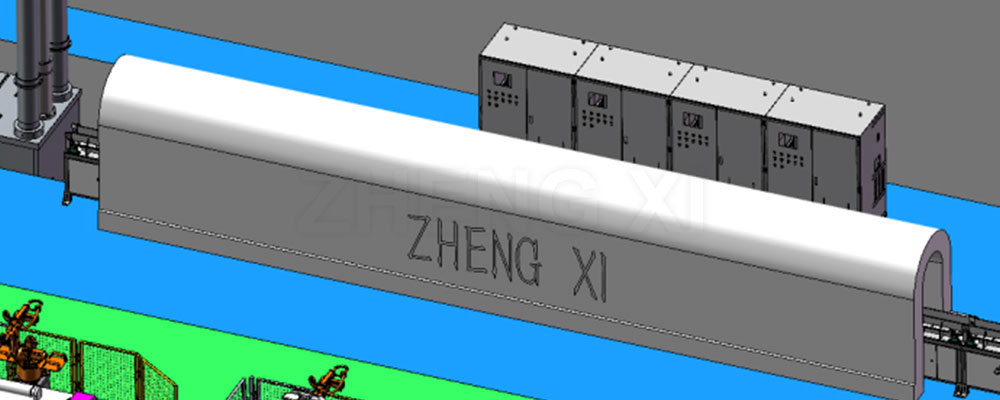

4.Cooling Room

After the rough forging is completed, the high-temperature parts are sent into the cooling room by the robot. After the cooling is completed, the robotic arm grabs the parts for the next process.

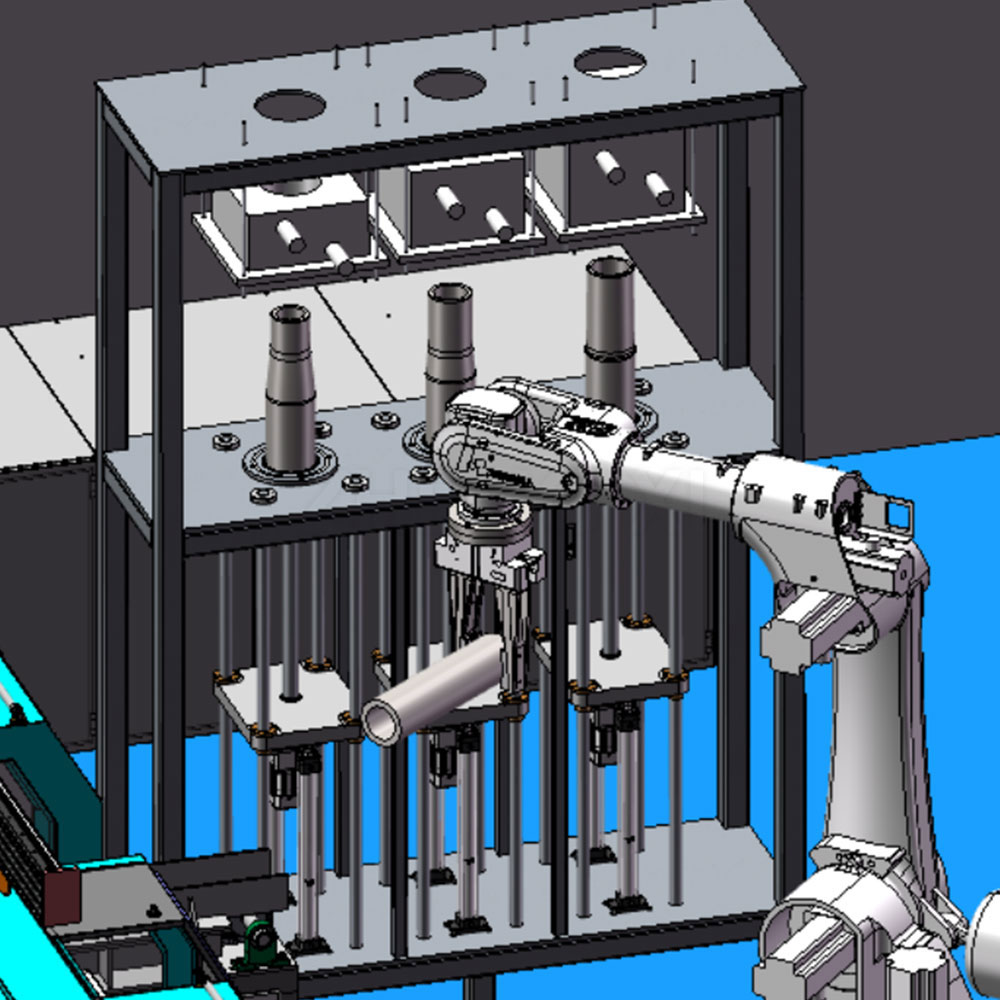

5.Induction Heating Unit

This is an induction heating station for heating parts of the blank. Then it is grabbed by a robot and put into an 800T forging machine.

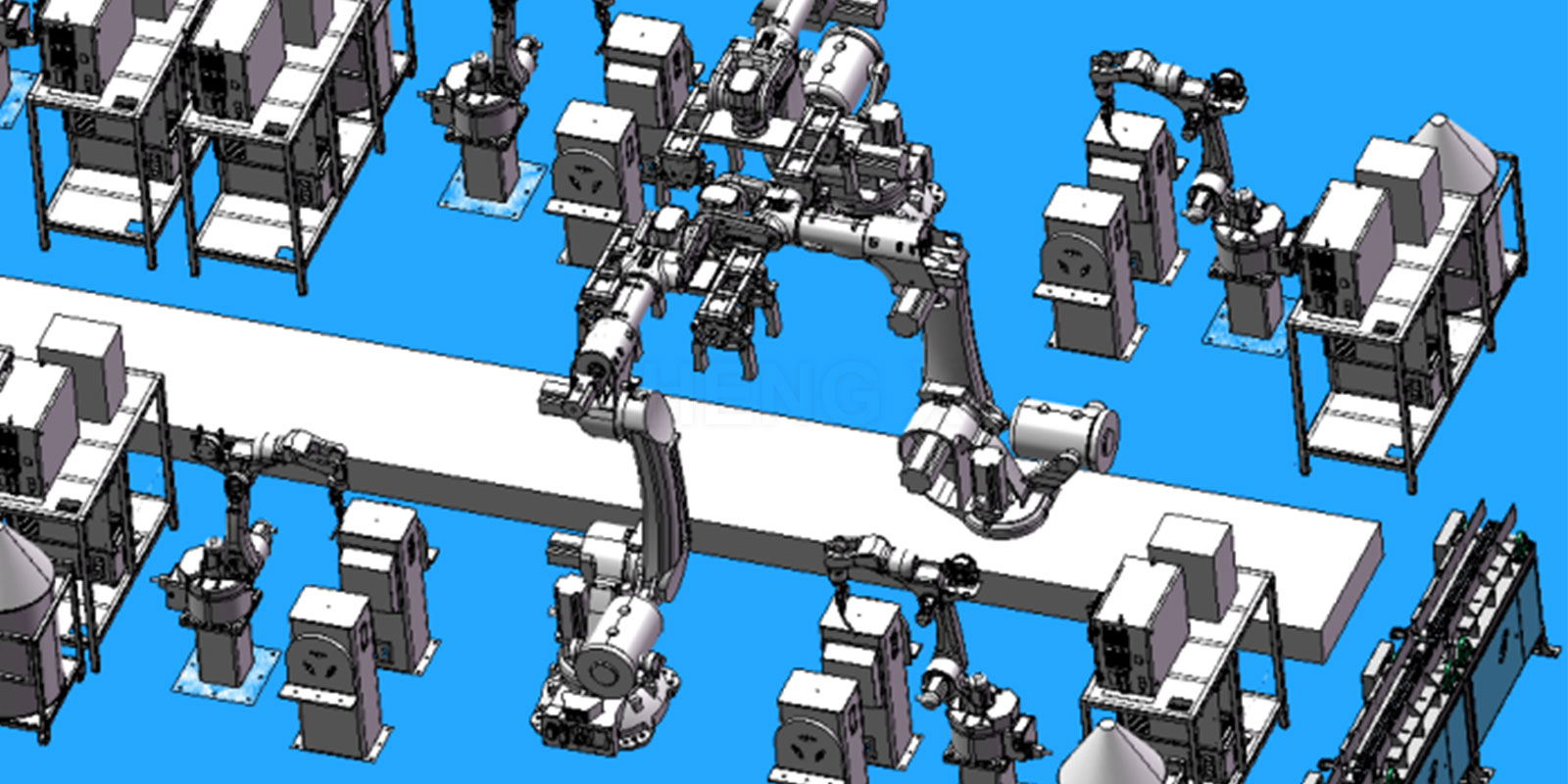

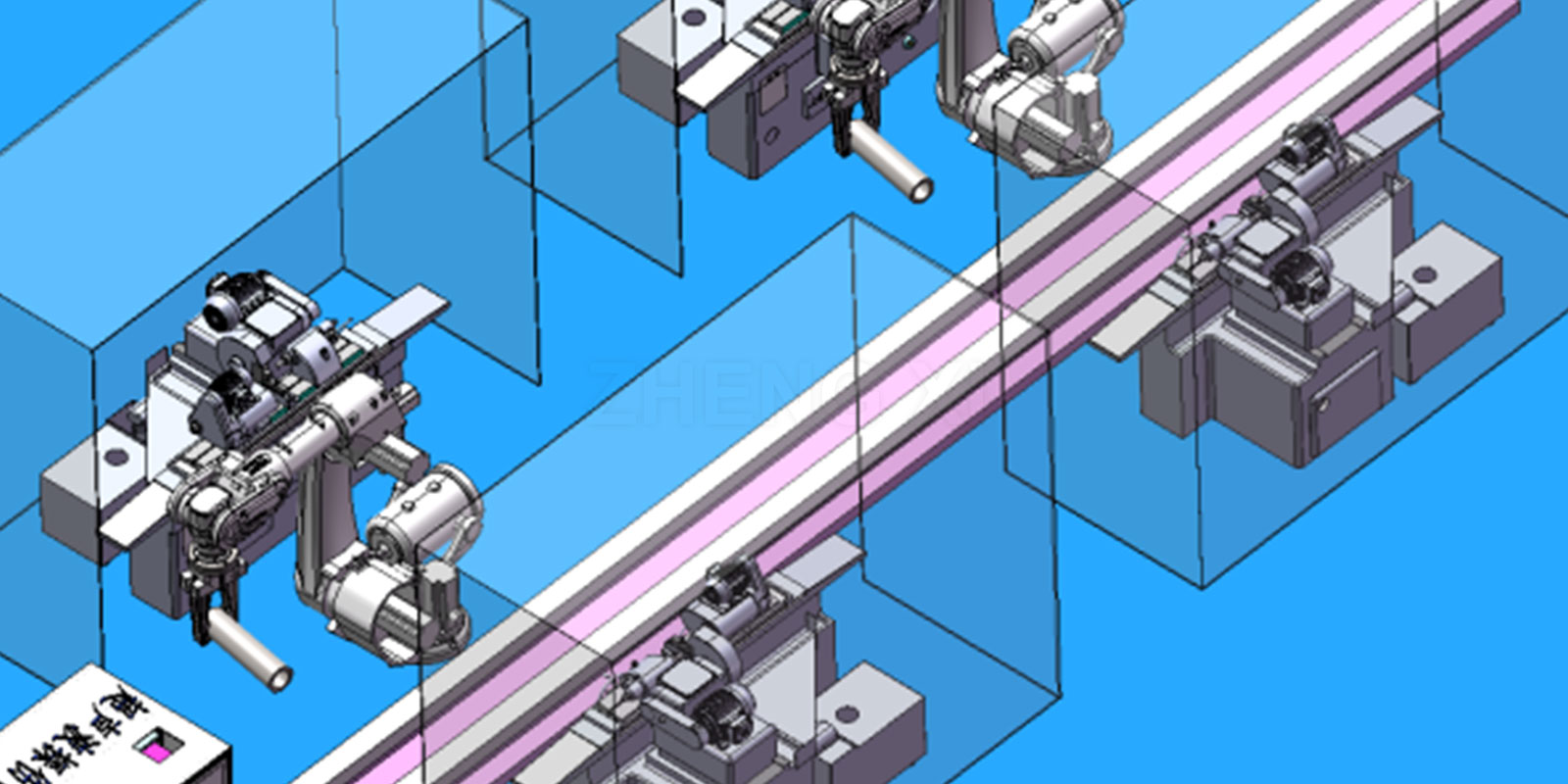

Fully automatic welding system, including two 210KG KUKA manipulators, ground rails, and 16 welding robots. The estimated welding speed is about 20 minutes for one piece/each welding machine. This welding line includes the structure to store the welding wire.

This is a fully automatic polishing system. It includes 4 sets of polishing stations and 2 sets of KUKA robots with 210 KG loading capacity. One station can make one pcs 8 minutes.

After the dimensions are checked, the shell will be moved to a hardness tester, to check the hardness of each part. And the hardness test area according to the drawing from the buyer.

Request A Quote

Learn more details about this forging press line. Please fill out the form below to contact us now.