The production efficiency of composite hot press molding machines is influenced by equipment performance, process parameters, and material properties. Overall efficiency is high, but there is still significant room for improvement.

1. The Impact of Equipment Performance on Production Efficiency

1) Pressure and Temperature Control

Hot press molding machines typically operate at pressures ranging from 100T to 500T. Using a servo closed-loop control system and segmented temperature control technology, temperature tolerances are kept within ±3°C. This high-precision control ensures stable hot press temperatures, significantly improving product yields while shortening molding cycles.

Heating and pressurizing machines utilize a mold temperature controller for heating and a PLC-controlled, multi-stage pressurization process. Both the heating and pressurization processes can be configured with multiple stages, enabling more precise temperature and pressure control. This segmented control method not only improves molding quality but also shortens production time.

2) Level of Automation

Modern hot press machines are generally equipped with a fully automatic PLC control system, which supports flexible settings for multiple pressure and stroke stages. The number and sequence of stroke and pressure stages can be adjusted at any time. This flexibility enables the machine to adapt to the production needs of diverse products quickly, significantly improving production efficiency.

2. The Impact of Process Parameters on Production Efficiency

1) Temperature Control

Temperature is a key factor affecting hot press molding efficiency. Precise temperature control ensures that the resin flows and solidifies within the appropriate range, avoiding material defects caused by excessively high or low temperatures. For example, excessively high temperatures may cause the resin to prematurely solidify or decompose, while excessively low temperatures prevent the resin from fully flowing, resulting in voids and cracks within the material.

2) Pressure Control

The role of pressure is to fully bond the carbon fiber and resin, remove excess resin and air, and improve the density of the product. Proper pressure control can shorten molding time while improving the mechanical properties of the product.

3) Time Control

Time includes heating time, holding time, and cooling time. The duration of each stage must be precisely set according to the resin type and product design requirements. Too short a processing time may result in insufficient resin flow or curing, while too long a processing time may cause the resin to overcure or degrade.

3. Impact of Material Properties on Production Efficiency

1) Carbon Fiber Properties

Carbon fiber offers advantages such as high tensile strength, excellent corrosion resistance, shock and vibration resistance, and impact resistance, as well as light weight and excellent flexibility. These properties enable carbon fiber to better bond with the resin during the hot press molding process, forming a high-strength composite material. Furthermore, the lightweight nature of carbon fiber reduces energy consumption during the molding process, improving production efficiency.

2) Resin Matrix

The choice of resin matrix also has a significant impact on hot press molding efficiency. A suitable resin matrix should exhibit good flowability and curing properties to ensure that the interstices between fibers are fully filled during the molding process, forming a dense composite structure.

4. Actual Production Efficiency Performance

1) Production Cycle

By optimizing process parameters and equipment performance, the production cycle of a thermoforming machine can be significantly shortened. For example, one model of thermoforming machine utilizes rapid vacuum and slow multi-stage pressurization technology, reducing the production cycle to less than 10 minutes, achieving highly efficient production.

2) Yield Rate

High-precision temperature and pressure control, along with optimal process parameter settings, ensure consistent product quality and performance, thereby improving yield rate. This increased yield rate not only reduces scrap loss but also enhances overall production efficiency.

3) Automation and Intelligence

Modern hot press machines are often equipped with automated and intelligent control systems, allowing for the full automation of the entire production process, from raw material input to finished product output. This production method not only improves production efficiency but also reduces labor costs and operational complexity.

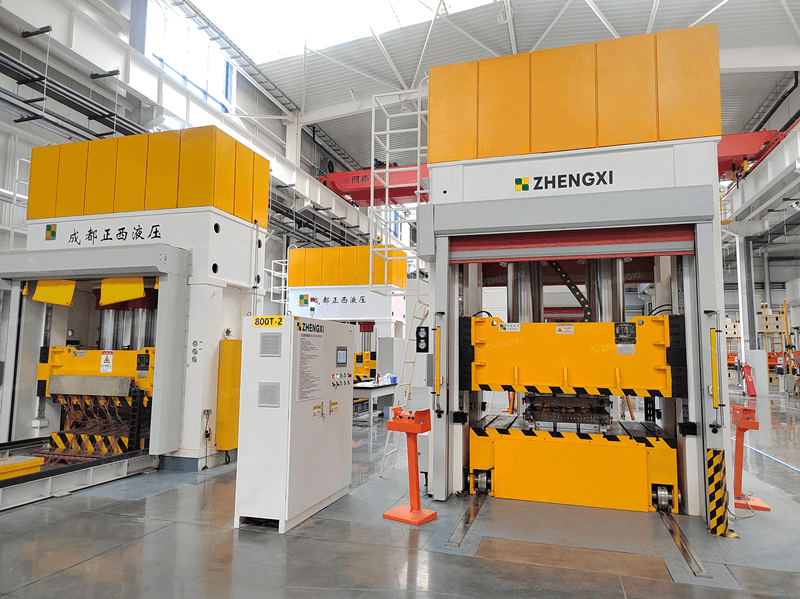

ZHENGXI is a professional hydraulic press machine factory that provides high-quality hot press machines with high production efficiency. If you have any needs, please contact us!