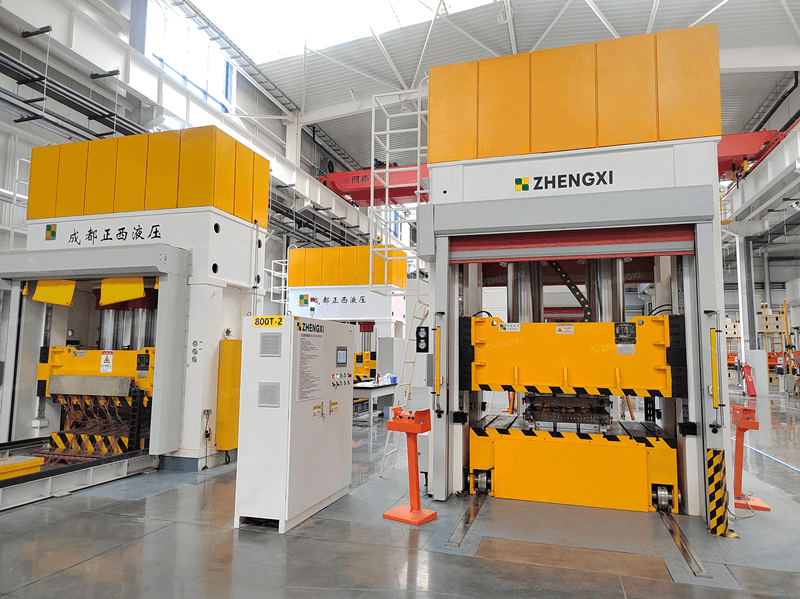

Rapid metal cold extrusion hydraulic press equipment implements the extrusion molding process, primarily used for extruding and forging metal materials, including roughing, stretching, drilling, bending, coining, and plastics. Chengdu Zhengxi Hydraulics produces vertical extrusion equipment powered by high-pressure liquid, with a maximum operating pressure of 22 MPa in the main cylinder. It features high-dimensional accuracy, high material utilization, high production efficiency, and high product strength. Customized frame or four-column (cold or hot) extrusion equipment is available.

Extrusion molding technology not only places a metal blank into the extrusion die cavity but also applies pressure to the blank at a specified temperature through a punch mounted on a metal cold extrusion hydraulic press, causing the blank to plastically deform and form the part. Based on the processing technology, it can be divided into cold extrusion and hot extrusion equipment. Based on the equipment structure, it can be divided into frame equipment and four-column equipment.

Performance and Features of the Metal Cold Extrusion Hydraulic Press:

1) The cylinder is integrally cast, ensuring high structural strength. Precision-ground to a high-gloss surface, the cylinder offers high reliability and impact resistance under high-pressure conditions. It is particularly suitable for metal extrusion, fully meeting the extrusion process’s pressure requirements. The master cylinder is available in a range of nominal forces from 1,000 kN to 10,000 kN.

2) The maximum operating pressure of the master cylinder fluid can be maintained at 22 MPa. This reduces oil pump load, extends pump life, reduces hydraulic vibration, lowers oil temperature, and maximizes equipment stability.

3) The machine utilizes a dual-speed mechanism. The master cylinder uses a piston-type design, with the master cylinder embedded in the slave cylinder. This reduces the cross-sectional area, enabling rapid lowering of the master cylinder even when oil levels are low. When the main cylinder approaches the product, the slave cylinder stops, allowing the mother cylinder to quickly form the part. This system features low no-load power consumption, fast mold clamping, and minimal power consumption for rapid deepening. Equipped with an intelligent sensing system and adaptive mode, it supports dual-speed, rapid control modes, including single-motor dual-system, single-motor single-system, dual-motor dual-system, and multiple-system.

4) The metal cold extrusion hydraulic press utilizes a large-diameter, internally inserted control valve, offering strong oil flow capacity, high flow rate, minimal pressure loss, and high reliability.

5) The three-beam plate is typically formed through a single-step CNC precision machining process. Through additional processing, the guide posts of the movable beam plate are twice as long as those of conventional guide posts, providing strong resistance to side loads and excellent rigidity.

6) The contactless relay control output ensures fast system response time and long service life, eliminating the lag in electrical component response caused by residual magnetism in traditional relays.

7) The actuator PLC is selected to adjust the loading path and control the molding process through an intelligent human-machine interface.

8) Two options are available: with a draft and without a draft. The main cylinder with the ejector has a significant return force, which is convenient for separation from deep extrusion workpieces. The return stroke is fast after ejection, saving space and time.

Applications of Metal Cold Extrusion Hydraulic Presses:

Metal cold extrusion hydraulic presses are suitable for extruding metal materials such as stepped shafts, disks, and gear parts, adjusting thickness, length, drilling, and bending. They are particularly well-suited for the extrusion and casting of aluminum products. They can also be used for printing, forming, shallow drawing, and plastic surgery of metal and non-metal parts.

Applicable industries include: aerospace plastic positioning, automotive parts, motorcycle parts, photo frames, transmission parts, tableware, signs, locks, hardware parts and tools, agricultural machinery parts, and other manufacturing industries.