Deep drawing is a stamping method that uses a deep drawing die to press the punched flat wool into hollow parts with various openings, or to process the made hollow parts with openings into hollow parts of other shapes. Deep drawing technology is widely used in production processes, such as the production of automotive parts. In addition, it can also be used to make household products, such as stainless steel kitchen sinks and so on.

Table of Content:

Definition of Deep Drawing

Deep Drawing Principle

Deep Drawing Method

Classification of Deep Drawing

Features of Deep Draw

The Structure of the Deep Drawing

Deep Draw Die

Application of Deep Drawing Process

1. Definition of Deep Drawing

Deep drawing, also known as drawing, stretching, calendaring, etc., refers to the process of stamping a flat blank of a certain shape obtained after punching into various open hollow parts by using a mold, or reducing the diameter of the open hollow blank and increasing the height.

The deep drawing process can be used to manufacture cylindrical, stepped, conical, spherical, box-shaped, and other irregularly shaped thin-walled parts. Cooperating with other stamping forming processes such as flanging, bulging, flaring, and shrinking, it can also manufacture parts with extremely complex shapes. Therefore, in the production process of automobiles, aircraft, tractors, electrical appliances, instruments, electronics, and other industrial sectors, the deep drawing process occupies a very important position.

The deep drawing equipment is mainly a press. During the deep drawing of cylindrical workpieces, the slab is reduced from its initial diameter to the cylindrical diameter of the stamping. The size of the deep drawing deformation is called the degree of deep drawing deformation. When the degree of deformation is large, the deformation force required for deep drawing may be greater than the strength of the side wall of the formed part, thus breaking the workpiece. In order to increase the degree of deep drawing deformation to produce satisfactory workpieces, the deep drawing with a large degree of deformation is often divided into two or more forming steps, gradually reducing the diameter and increasing the height.

2. Deep Drawing Principle

Due to the different geometrical characteristics of the drawn parts, there are considerable differences in the position of the deformation zone, the nature of the deformation, the distribution of the deformation, and the stress state and distribution law of each part of the blank during the drawing process.

Taking the straight wall rotary cylindrical part as an example, the working principle of the deep drawing process is explained.

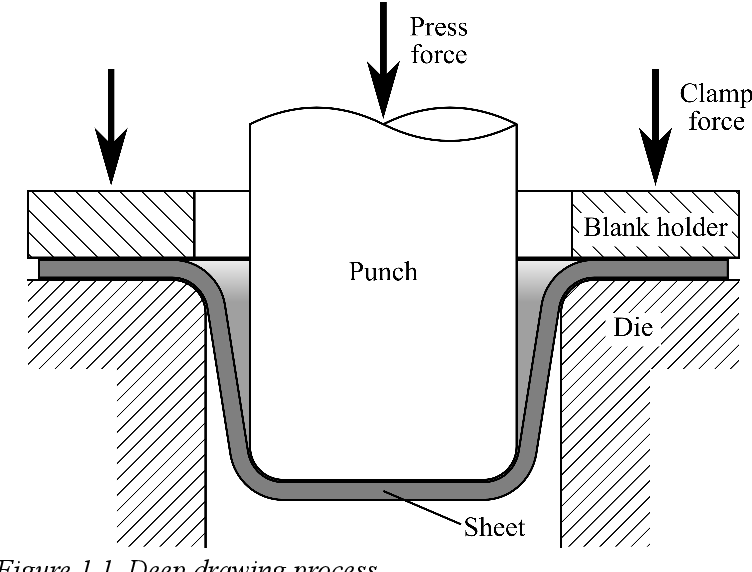

Under the action of the punch, the flat or hollow blank is plastically deformed in the annular part of the blank placed between the die and the blank holder and is continuously pulled into the gap between the punch and the die by the punch to form a part. The process of drawing a flat blank into a hollow part is called the first deep drawing, and drawing a hollow blank with a larger diameter into a hollow part with a smaller diameter is called deep drawing again.

The deformation of the first drawing process occurs in the annular part, which is called the flange deformation zone. The deformation circumferential direction (tangential direction) of the blank in the deformation zone is compression deformation, and the radial direction is elongation deformation. The redrawn deformation zone is also an annular zone. The width of the deformation zone remains unchanged for a long period of time, and only when the height of the deformation zone decreases continuously, the deformed zone continues to increase. When the height of the deformation zone is zero, the width of the deformation zone gradually decreases until the deformation ends. The deformation properties in the deformation zone are similar to those of the first deep drawing, with compression deformation in the tangential direction and elongation deformation in the radial direction.

3. Deep Drawing Method

Deep drawing of low cylindrical parts

For shallower drawn parts, generally use blanking dies for drawing or drawing methods with edge-extruded drawing dies.

Deep drawing, shape correction, and trimming methods can be used for deep-drawn parts with high requirements on surface quality.

Or swing trimming or lathe trimming after deep drawing.

Deep drawing of tall cylindrical parts

For high cylindrical deep-drawn parts, multiple re-drawing methods are generally used, including re-drawing methods without flanges, re-drawing methods with small flanges, and reverse-drawing methods after re-drawing.

4. Classification of Deep Drawing

Deep drawing comes in many forms. According to the shape of the parts, deep drawing can be divided into cylindrical parts, conical parts, hemispherical parts, stepped parts, box parts, and complex shape parts. According to the number of processes, deep drawing can be divided into single and multiple deep drawings. According to the material deformation, deep drawing can be divided into positive deep drawing, reverse deep drawing, thinning deep drawing, and special deep drawing. Deep drawing of cylindrical parts is the most basic deep drawing method in various deep drawing forming processes.

5. Features of Deep Draw

The deep drawing process has high productivity and high material utilization.

It has certain dimensional accuracy and low surface roughness. It can manufacture deep-drawn parts as small as a few millimeters (such as hollow rivets) and as large as several meters (such as automobile panels) and thin-walled and complex parts that are not easily formed by other processing methods.

It occupies a very important position in the production of machinery, electronics, electrical appliances, instruments, automobiles, aviation, military products, and people’s daily necessities.

6. The Structure of the Deep Drawing

The geometric shape of deep-drawing parts can be divided into three categories: deep-drawing of rotating body parts, deep-drawing of box-shaped parts, and deep-drawing of complex-shaped parts. Among them, the rotating body drawing parts can be divided into flangeless cylindrical parts, flanged cylindrical parts, hemispherical parts, conical parts, parabolic parts, stepped parts, complex rotating body drawing parts, etc.

7. Deep Draw Die

The tool used to realize the deep drawing process is called a deep drawing die. Compared with the blanking die, the structure of the drawing die is relatively simple, the working part has a large rounded corner, the surface quality is high, and the gap between the convex and concave dies is slightly larger than the thickness of the sheet.

According to the equipment used in the drawing die, it can be divided into:

- single action press

- double action press

- Three-action press

Divided by process combination:

- Single process drawing die

- Progressive drawing die

- Composite mold

8. Application of Deep Drawing Process

Common deep-drawing products in daily life include rotating body parts: such as enamel washbasins and aluminum pots.

Square parts: such as lunch boxes, and automobile fuel tanks.

Complex parts: such as automotive panels.

Automobile bodies, fuel tanks, pots, cups, and boiler heads are all deep-drawing parts.

Zhengxi is a famous hydraulic press manufacturing company with professional stamping knowledge. Follow us to know more information.