Common faults and solutions for die-forging hydraulic presses when producing metal parts are as follows:

1. Hydraulic System Failures

1) Insufficient or Fluctuating Pressure

Causes: Improper pressure/flow adjustment, wear, or internal leakage in the hydraulic pump (e.g., gear pump, plunger pump); malfunction of control valves such as the relief valve and unloading valve; clogged hydraulic oil filter or oil contamination.

Solution: Readjust the pump’s pressure and flow parameters to ensure they meet process requirements.

Replace worn internal pump parts (e.g., plunger, manifold plate) or seals.

Clean or replace the hydraulic oil filter, and regularly replace hydraulic oil that meets specifications.

2) System Overheating

Causes: Frictional heating of the hydraulic oil within the pipeline, internal friction caused by uneven oil flow, or cooling system failure.

Solution: Improve the cooling system to ensure efficient heat dissipation.

Use high-quality hydraulic oil to reduce internal friction.

Optimize the pipeline layout, avoiding sharp bends or narrow sections to reduce flow resistance.

3) Hydraulic Cylinder Failure

Symptoms: Hydraulic cylinder inoperative, abnormal speed, creeping, or vibrating.

Cause: Leakage due to damaged seals; blockage in the hydraulic oil line; air ingress into the cylinder.

Solution: Replace the hydraulic cylinder seals and inspect and clean the oil lines.

System Ventilation Procedure: Slightly loosen the pipe joint while applying pressure to bleed air.

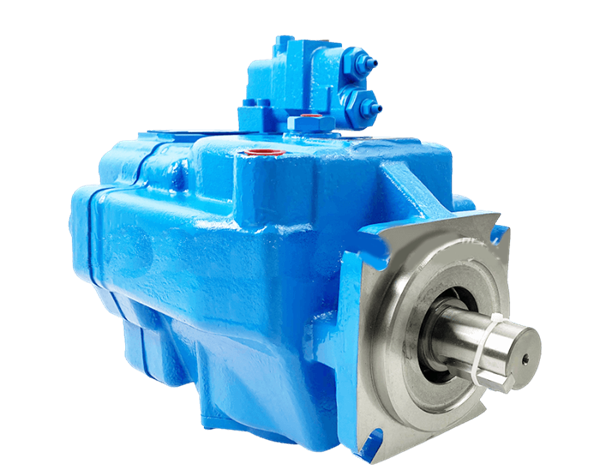

2. Hydraulic Pump Failure

1) Pump Fails to Suction or Outputs Insufficiently

Causes: Pump ingests air (e.g., suction pipe leak); internal pump wear (e.g., excessive clearance between plunger and cylinder); motor speed mismatch or bearing damage.

Solution: Check the suction pipe seal and eliminate leaks.

Replace worn pump parts (e.g., plunger, distribution plate) and adjust motor speed.

2) Excessive Pump Noise or Vibration

Causes: Plunger wear, poor lubrication, distribution plate failure, improper drive shaft tension.

Solution: Inspect and maintain the plunger and distribution plate to ensure adequate lubrication.

Adjust the drive system tension to the appropriate level.

3. Control Valve Failure

1) Directional Control Valve Failure

Symptoms: Incorrect shifting, slow main valve operation, or stuck main valve.

Causes: Worn pilot valve push rod; valve core stuck by debris; loose solenoid mounting screws.

Solution: Replace the worn pilot valve push rod and clean the valve core of debris.

Tighten the solenoid screws and adjust the solenoid position.

2) Pressure Control Valve Failure

Symptoms: Unstable pressure, inability to maintain pressure.

Cause: Deformed or leaking relief valve or unloading valve springs; pressure regulating valve failure.

Solution: Replace the spring or seal, and repair the pressure regulating valve.

4. Electrical Control System Failure

1) Motor Failure

Symptoms: Motor tripping, overheating, or failure to start.

Cause: Reverse motor phase wiring, malfunctioning thermal relay, bearing damage.

Solution: Correct the motor phase wiring sequence and reset the thermal relay.

Replace the bearing or the entire motor.

2) PLC or Sensor Failure

Symptoms: System malfunction or abnormal data.

Cause: Sensor damage, PLC program error, or network communication failure.

Solution: Replace the faulty sensor, check the PLC program, and correct any logic errors.

Check the network connection to ensure stable communication.

5. Mechanical Component Failure

1) Seal Damage

Symptoms: Hydraulic oil leakage or pressure drop.

Cause: Deterioration of the seal, improper installation, or contamination of the hydraulic oil.

Solution: Replace the seal and ensure proper installation.

Replace the hydraulic oil regularly to keep it clean.

2) Plunger Scratches

Symptoms: Scratches and leakage on the plunger surface.

Cause: A bolt has fallen off and into the hydraulic cylinder, scratching the plunger wall.

Solution: On-site repair using polymer composite materials: sand down the scratched area, apply the repair material, and grind it smooth after curing.

Auxiliary System Malfunction

1) Low Fuel Tank Level

Symptoms: Insufficient pump oil intake, system vibration.

Cause: Clogged fuel tank filter; inadequate oil replenishment.

Solution: Clean the fuel tank filter and add sufficient hydraulic oil.

2) Pressure Gauge Malfunction

Symptoms: Fluctuating needle, no display.

Cause: Clogged pressure gauge seat; damaged pressure gauge.

Solution: Clean the pressure gauge seat and replace the faulty pressure gauge.

As a professional forging press manufacturer in China, ZHENGXI provides not only high-quality die forging machines but also professional maintenance plans. If you have any needs, please contact us!