A ceramic powder hydraulic press is a type of hydraulic press for powder molding. It’s a hydraulic device designed explicitly for compacting ceramic powders. During compaction, multiple, staged degassing operations eliminate air trapped in the blank, reduce porosity, and achieve the desired density. Depending on the characteristics of the ceramic powder, commonly available capacities include 200-ton, 315-ton, 400-ton, 500-ton, 630-ton, 800-ton, and 1000-ton capacities.

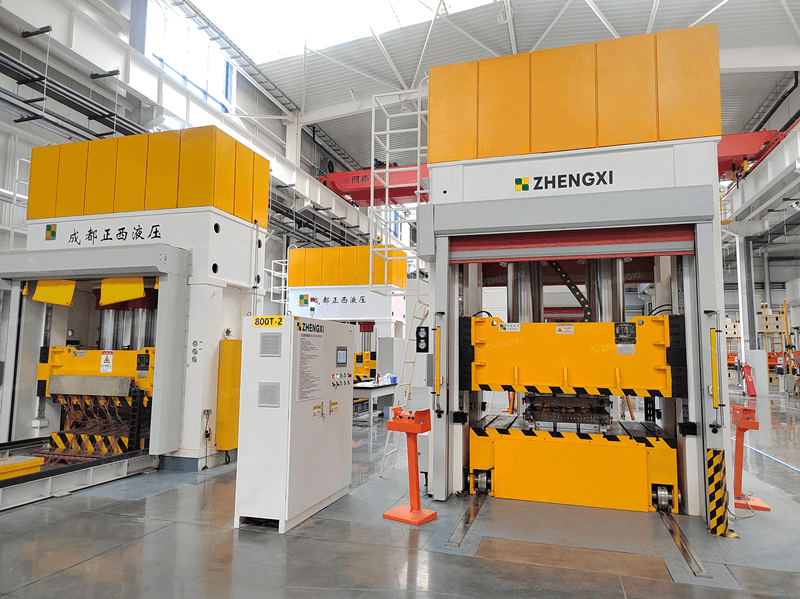

Zhengxi‘s 1000-ton ceramic powder hydraulic press features a three-beam, four-column structure and an electronic control system equipped with servo and industrial touchscreen PLC automation. It can handle pre-pressing, floating pressing, bidirectional pressing, post-pressing, and ejection processes, ensuring automated production and high efficiency. Our 1000-ton ceramic powder hydraulic press offers customizable degassing times for high compaction efficiency. A multi-stage hydraulic system ensures smooth demolding and a high crucible density. It provides advantages such as zero vibration, low noise, uniform density, and minimal porosity.

Features of the 1,000-ton Ceramic Powder Molding Hydraulic Press:

- The 1,000-ton Ceramic Powder Molding Hydraulic Press adopts a three-beam, four-column design, making it economical and practical.

- The lower ejector cylinder offers high ejection force and bidirectional pressurization. A core-pulling cylinder is built into the lower section of the cylinder. The core-pulling stroke can be customized according to customer product requirements.

- The electronic control system is equipped with a servo and an industrial touchscreen PLC automation. A wire gauge displacement sensor is installed on one side of the crossbeam. The system features a position-controlled exhaust function, which adjusts the exhaust stroke position based on the compression ratio and working stroke of the powder molded product. All signals and data can be set via the touchscreen.

- The electronic control system of the 1,000-ton Ceramic Powder Molding Hydraulic Press is integrated into the power cabinet and connected to a removable operating table. Aviation plugs are used for connection, making it aesthetically pleasing, easy to maintain, and convenient to use.

- All pressure oil line connections utilize SAE flanges for enhanced security and reduced oil leakage.

- Equipped with a safety grating and emergency stop button, it offers enhanced safety. 5. High productivity. A continuously variable top-pressing method ensures uniform compact density, high demolding pressure, and quick and accurate adjustment of all pressing operations.

- The hydraulic system of the 1000-ton ceramic powder molding hydraulic press utilizes an advanced combined stacking valve block to ensure continuous, stable, and reproducible operation. Mechanical stops at the three positions of loading, molding, and demolding ensure stable and adjustable product geometry. The advanced, optimized hydraulic transmission system enables automated molding, reducing labor intensity and significantly improving production efficiency.

- The equipment requires no manual operation, reducing the risk of safety accidents and ensuring operator safety. It boasts a high degree of automation.

- The pressure, exhaust times, and dwell time of the 1000-ton ceramic powder molding hydraulic press can be adjusted according to the characteristics of the raw material, enabling direct molding even with relatively fine raw materials.

Precautions for Use with a 1000-ton Hydraulic Press for Ceramic Powder Molding:

- The 1000-ton hydraulic press must be adequately grounded, preferably with a separate ground connection.

- Do not adjust the mold while the machine is running.

- Use No. 46 anti-wear hydraulic oil or No. N46 low-viscosity hydraulic oil, filtered through an 80-100 mesh molybdenum filter.

- After 200 hours of operation, check the oil cleanliness of the hydraulic press for odor-free operation. Place a drop of oil on a white piece of filter paper. If there is no black stain within the center of the oil stain, change the oil.

- Do not overload the 1000-ton three-beam four-column hydraulic press.

- If the system leaks unexpectedly, refill the hydraulic oil after the fault.

- Regularly check the pump station and oil tank for cleanliness. Water, dust, and foreign matter must not enter the oil tank.

- When switching functions, exhaust all air from the system before operation.

- If any abnormalities occur during testing or operation, stop the machine immediately for inspection.

- Maintain pressure for 10 minutes, then allow a 2.5 MPa pressure drop.

Powder-forming hydraulic presses are suitable for compacting ceramic powder products of various specifications and for forming powders of different materials. A 1,000-ton hydraulic press for ceramic powder forming is custom-made and priced between 400,000 and 800,000 RMB. Specific pricing should be determined directly by the hydraulic press manufacturer, depending on the work surface, opening, stroke, and configuration of the press. Please contact us if you require any information.